Disposable veress needle manufacturing method and veress needle manufactured by same

A manufacturing method and Veress needle technology, applied in the field of medical devices, can solve the problems of inability to judge whether the puncture is in place, damage to internal organs by the puncture needle, and damage to internal organs in the pelvic and abdominal cavity, so as to prevent accidental injury to internal organs and improve safety and effectiveness. sex, and the effect of avoiding cross-infection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

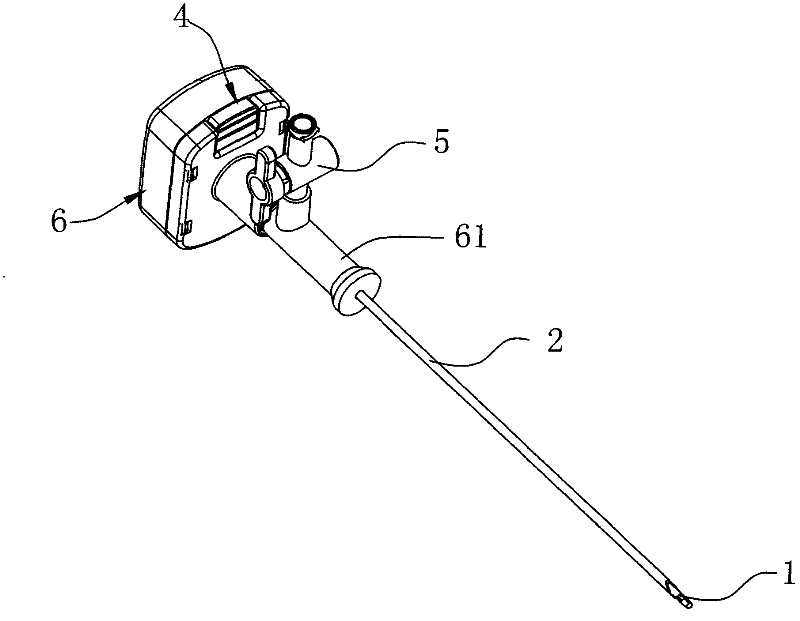

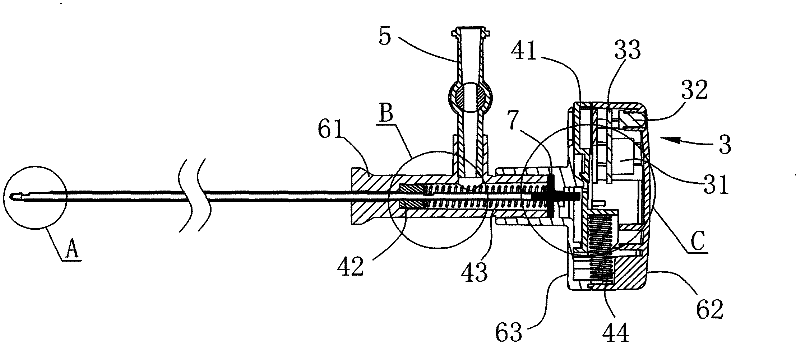

[0052] Example: see Figure 1 to Figure 12 , the embodiment of the present invention provides a disposable Veress needle manufacturing method, which includes the following steps:

[0053] A method for manufacturing a disposable Veress needle, comprising the steps of:

[0054] (1) a handle 6 provided with a control valve 5 is provided;

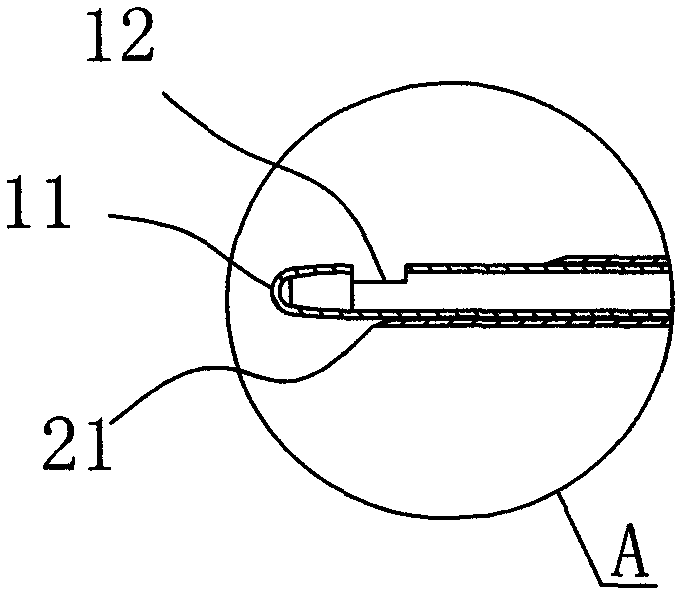

[0055] (2) a needle core 1 is set;

[0056] (3) a puncture needle 2 is set;

[0057] (4) a protective device 4 is set;

[0058] (5) Sound and light warning device 3 is set;

[0059] (6) Fix the puncture needle 2 on the handle 6, insert the needle core 1 into the puncture needle 2, and make the head end of the needle core 1 slightly protrude from the needle point of the puncture needle 2, so that The tail end of the needle core 1 extends into the handle 6 and is connected with the control valve 5, and the protection device 4 is arranged in the handle 6 corresponding to the tail end position of the needle core 1, and the protection device 4 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com