Two-phase carbon dioxide collecting device

A carbon dioxide, circulating pump technology, applied in inorganic chemistry, carbon compounds, chemical instruments and methods, etc., can solve the problem of high energy consumption, achieve the effect of strong absorption capacity and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

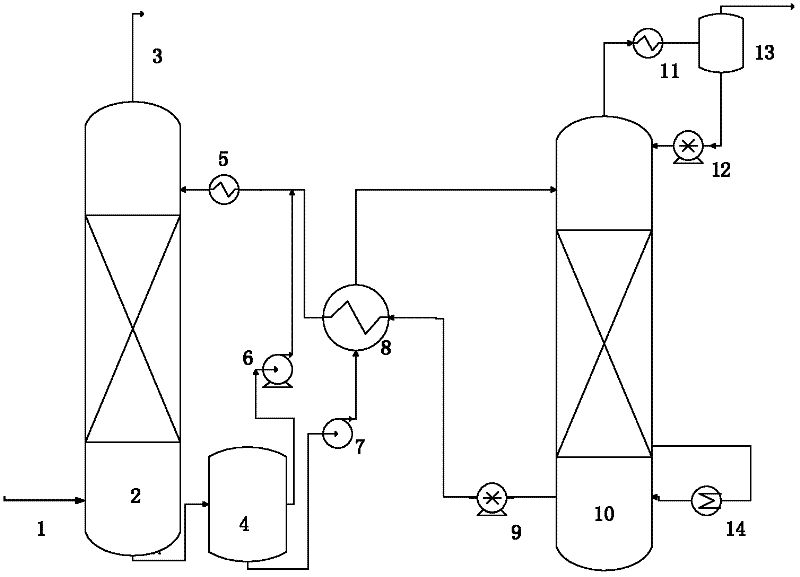

[0019] A two-phase carbon dioxide capture device (such as figure 1 shown), the bottom of the absorption tower 2 is connected with the separator 4, the middle or upper part of the separator 4 is connected with the first circulating pump 6, the bottom of the separator 4 is connected with the second circulating pump 7, and the first circulating pump 6 is connected with the The first heat exchanger 5 is connected to the top of the absorption tower 2, the second circulating pump 7 is connected to the poor-rich liquid heat exchanger 8, and the rich liquid heat exchanger 8 is respectively connected to the first heat exchanger 5, the top of the desorption tower 10, The third circulating pump 9 is connected, the third circulating pump 9 is connected with the bottom of the desorption tower 10, the regeneration device 14 is connected with the bottom of the desorption tower 10, and the top of the desorption tower 10 is connected with the second heat exchanger 11 and the fourth circulation ...

Embodiment 2

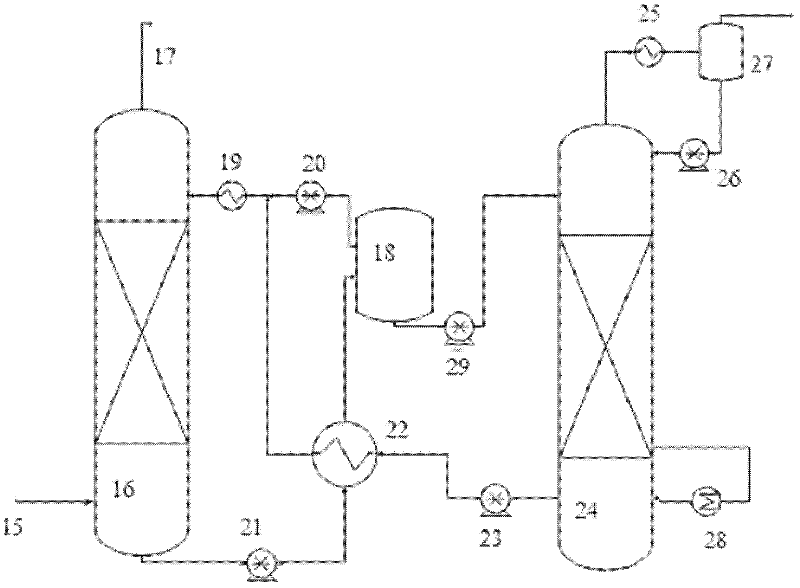

[0023] A two-phase carbon dioxide capture device (such as figure 2shown), the bottom of the absorption tower 16 is sequentially connected with the first circulation pump 21 and the lean-rich liquid heat exchanger 22, and the lean-rich liquid heat exchanger 22 is respectively connected with the first heat exchanger 19, the separator 18, and the second circulation pump 23 is connected, the third circulation pump 20 is connected with the first heat exchanger 19, the separator 18 is connected with the third circulation pump 20 and the fourth circulation pump 29 respectively, the second circulation pump 23 is connected with the bottom of the desorption tower 24, and the fourth Circulation pump 29 links to each other with the top of desorption tower 24, and regeneration unit 28 is connected at the bottom of desorption tower 24, and the top of desorption tower 24 connects the second heat exchanger 25 and the 5th circulation pump 26 respectively, the second heat exchanger 25 and the 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com