Compression molding method without action of inner rings for integral self-lubricating joint bearings

A joint bearing and molding technology, which is applied in the field of bearing manufacturing, can solve the problems of low reliability, uneven force, uneven force, etc., and achieve the effects of high reliability, long service life, and increased yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

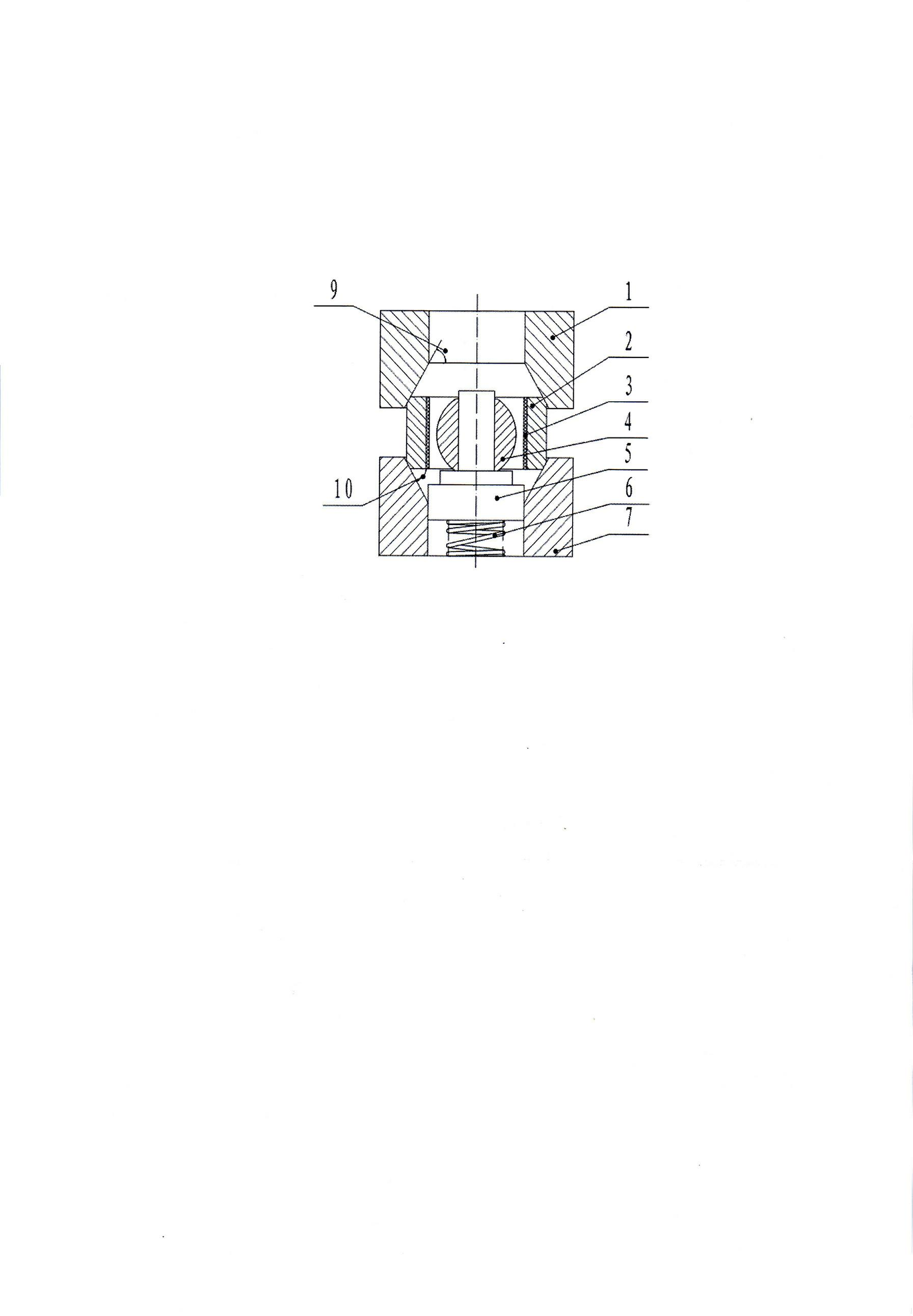

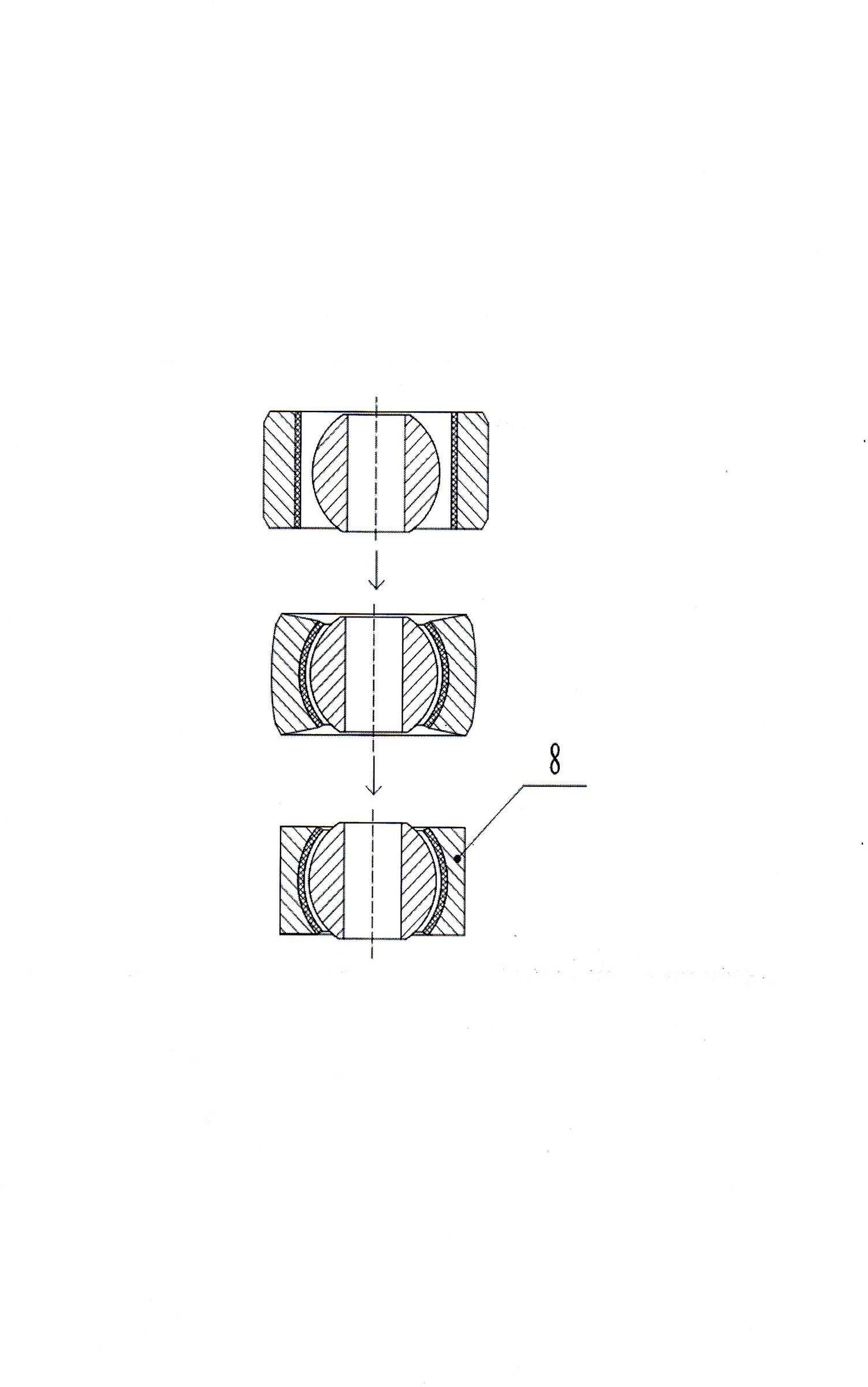

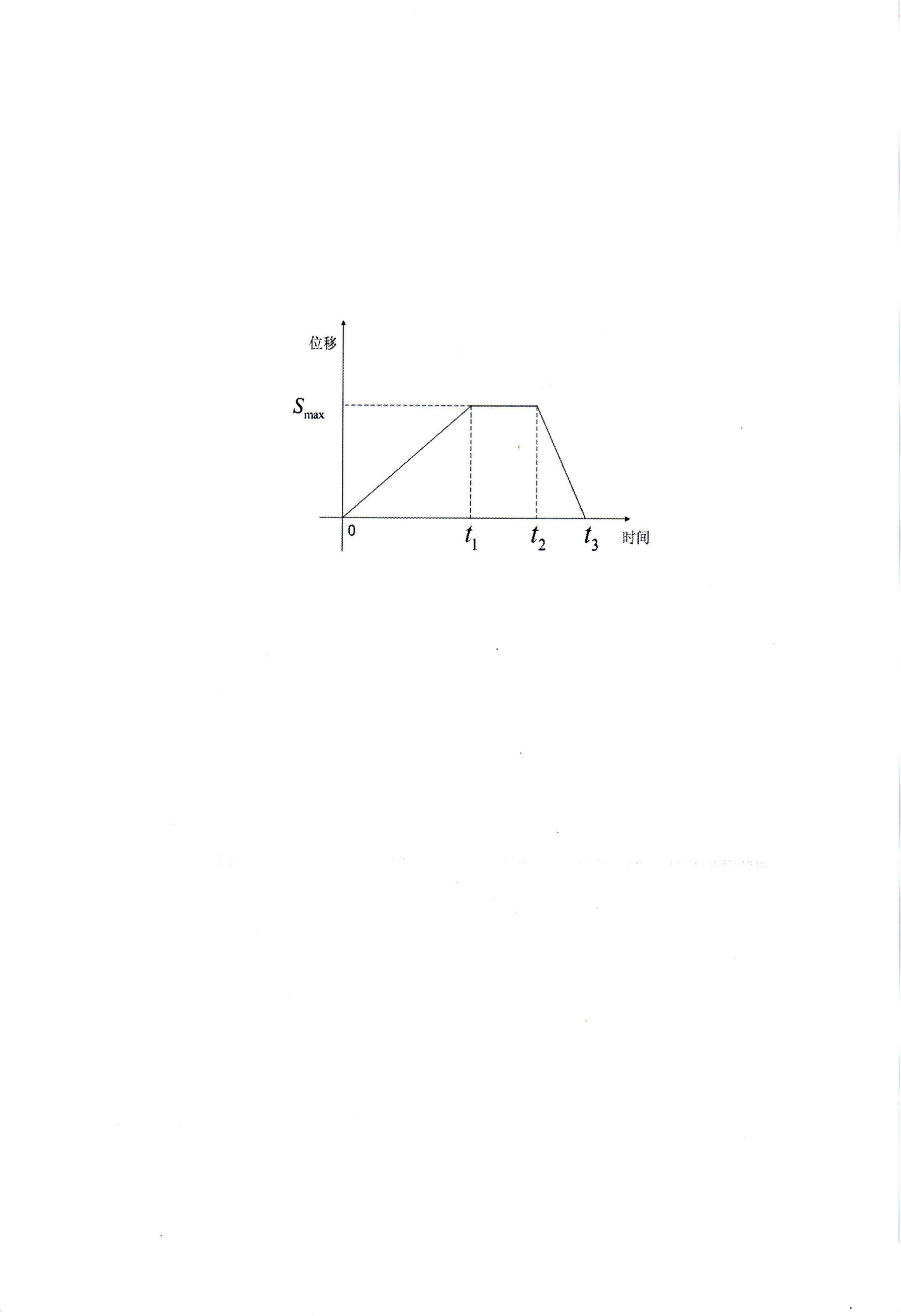

[0012] According to attached figure 1 , 2 , 3, the outer ring blank 2 of the integral self-lubricating spherical plain bearing is a circular cylinder. According to the requirements of different products for the outer ring blank, the outer ring blank is manufactured by turning, and the inner surface of the outer ring blank is polished. , the self-lubricating layer 3 is adhered on the inner surface of the outer ring blank after grinding. Put the bearing inner ring 4 in the outer ring blank adhered with a self-lubricating layer to form a whole bearing blank; the cavities of the upper mold 1 and the lower mold 7 are both conical surfaces, and there is a cylindrical hole in the middle of the mold, and the upper mold The cavity taper angle 9 and the lower mold cavity taper angle 10 are between 20°~70°. The integral bearing blank is placed on the mandrel 5 in the lower mold cavity, and the end surface of the outer ring blank has a width matching the cavity taper surface The chamfer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com