Machining method of step end face balance hole

A processing method and technology for balancing holes, which are applied in metal processing equipment, metal processing mechanical parts, manufacturing tools, etc., can solve the problems such as the inability to guarantee the dimensional accuracy of the balancing holes and the low precision of the step end face of the steam turbine rotor, and achieve optimal allowance distribution. and cutting parameters, the effect of improving processing efficiency and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

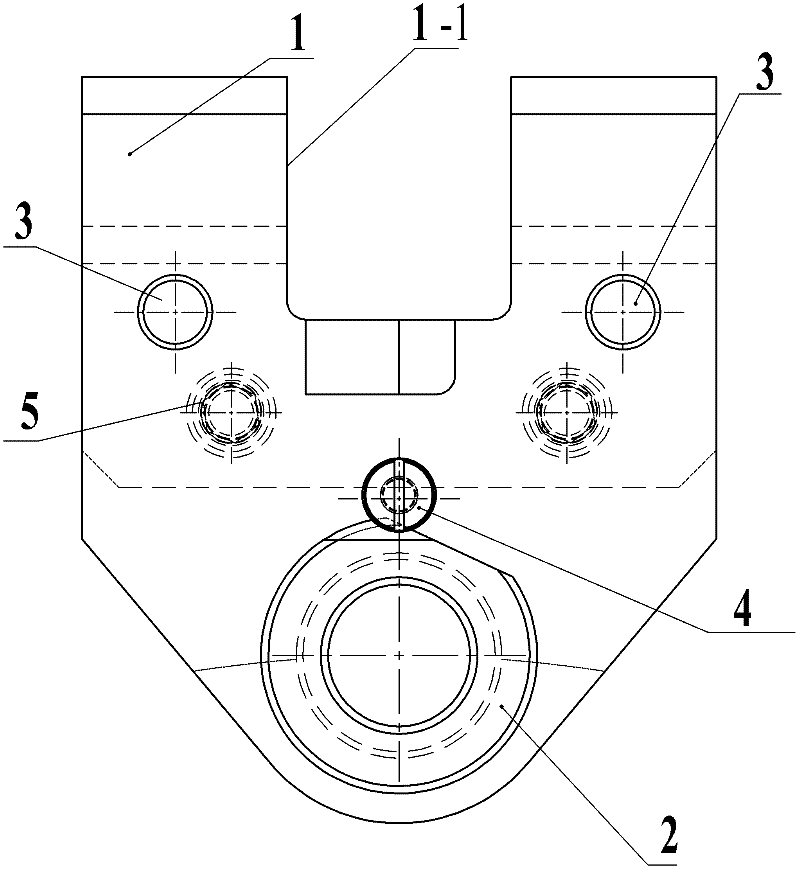

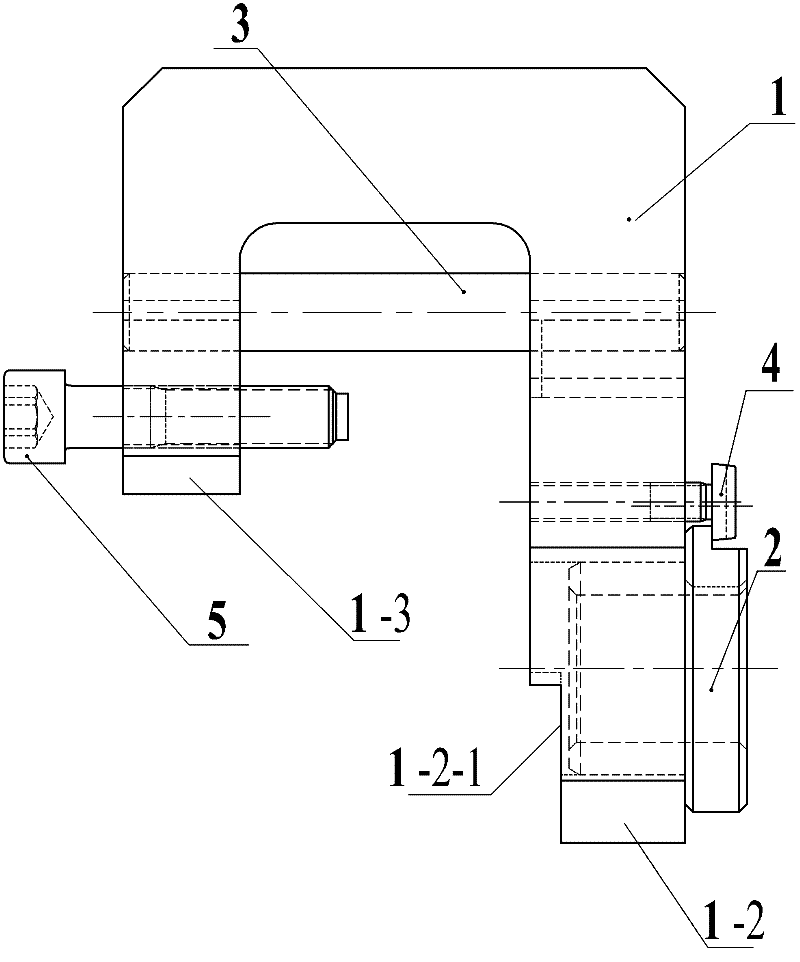

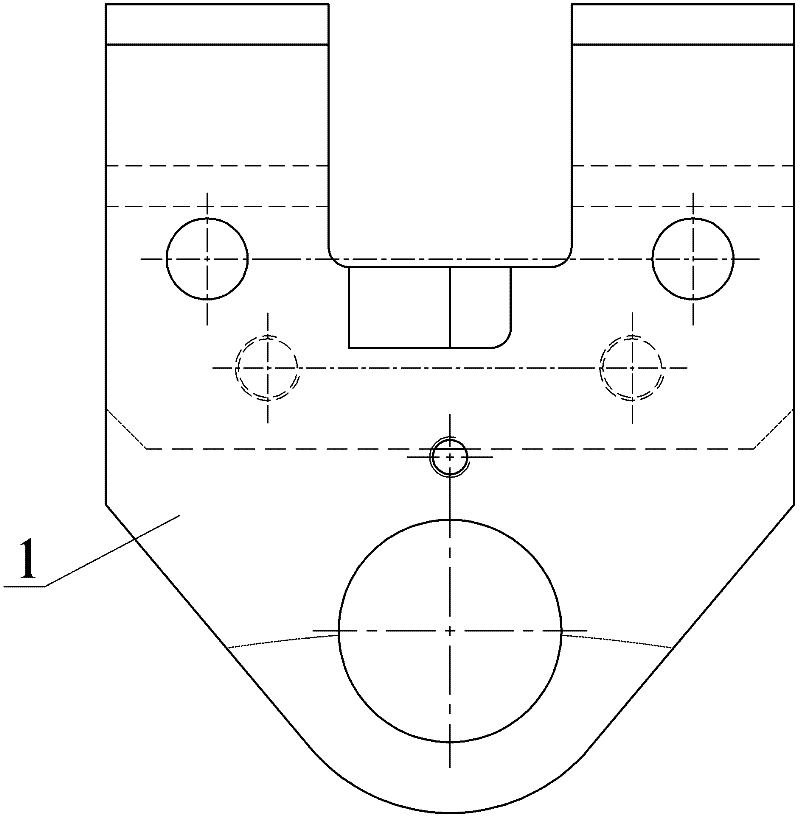

[0009] Embodiment 1: A processing method for the balance hole on the end face of a step is carried out according to the following steps: 1. Drilling: according to the set hole position, the special fixture is positioned and installed on the rotor end face of the pre-drilled hole, and the Φ30 drill sleeve and the drill sleeve are installed. Φ30 drill bit, and clamp the drill sleeve on the clamp body, use the Φ30 drill bit to drill, the cutting parameters are: speed 160-200r / min, feed rate 0.25-0.35mm / r; 2. Reaming: after drilling is completed , remove the Φ30 drill sleeve, install the Φ37.5 drill sleeve and the Φ37.5 reamer, and clamp the drill sleeve on the clamp body, use the Φ37.5 reamer to ream the hole, and the cutting parameters are: speed 125~160r / min, feed rate 0.3~0.4mm / r; 3. Reaming: After reaming, remove the Φ37.5 drill sleeve, install the Φ38 drill sleeve and Φ38 reamer, and clamp the drill sleeve on the clamp body , using a Φ38 reamer for reaming, the cutting para...

specific Embodiment approach 2

[0011] Embodiment 2: This embodiment differs from Embodiment 1 in that the inner side of the long side wall 1-2 of the special fixture is provided with a shoulder 1-2-1.

specific Embodiment approach 3

[0012] Specific embodiment three: the difference between this embodiment and specific embodiment one is that the shaft end of the drill sleeve 2 is provided with a small shoulder 2-1, and the small shoulder 2-1 is used to correspond to the nail cap of the drill sleeve set screw 4 Cooperate, the end face of the shaft end of the drill bushing 2 is in an excellent arc shape.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com