Optical anti-counterfeit element

An optical anti-counterfeiting and component technology, applied in the direction of diffraction gratings, chemical instruments and methods, synthetic resin layered products, etc., can solve the problems of incompatibility with the grating structure, combination, coating color is not rich, etc., to achieve new optical effects, simple structure , rich color effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The optical anti-counterfeiting element according to the present invention will be described in detail below with reference to the accompanying drawings.

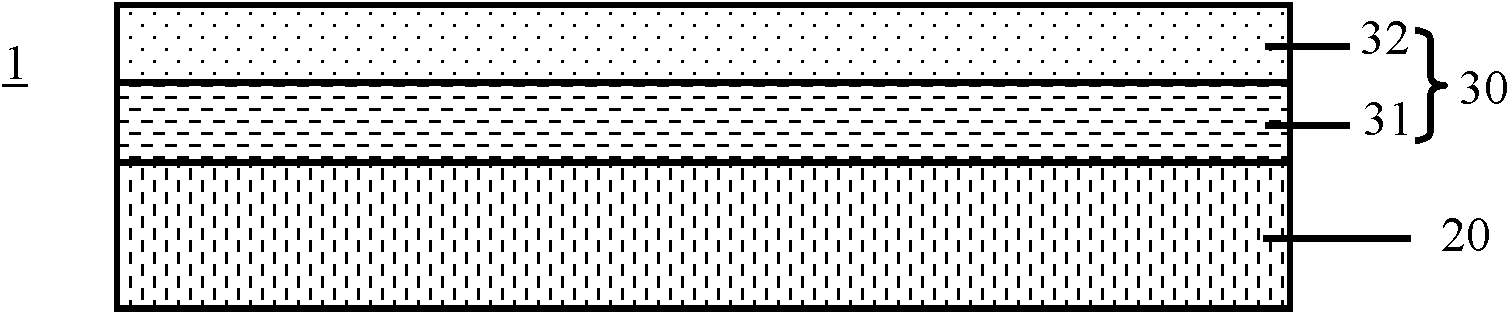

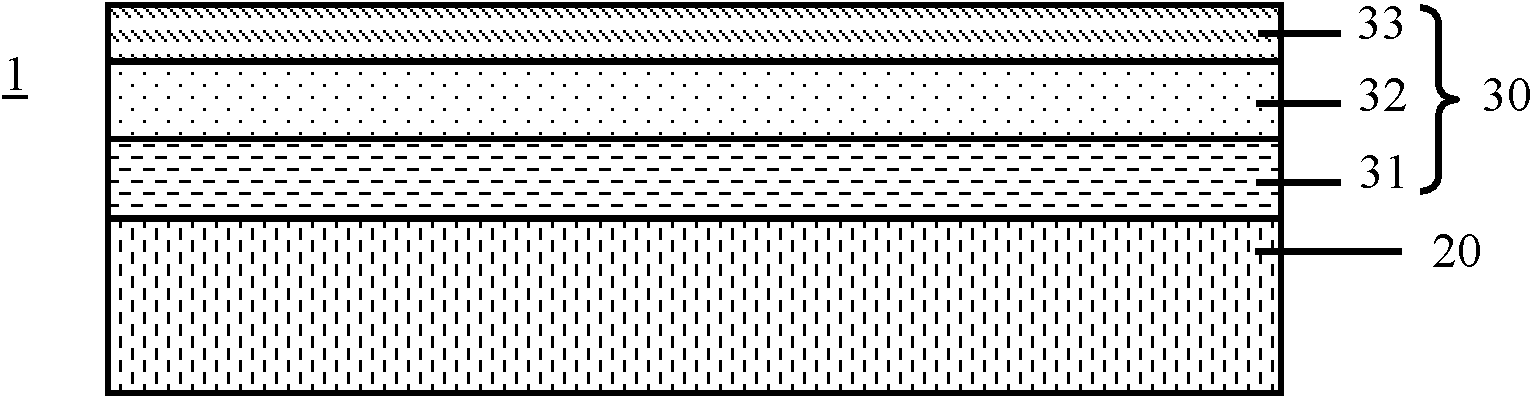

[0021] figure 1 A cross-sectional view of an optical anti-counterfeit element 1 according to an embodiment of the present invention is shown, wherein the optical anti-counterfeit element 1 includes a substrate 20 and a first coating 30, and the substrate 20 includes a first surface and a second surface, so The first coating layer 30 includes a reflective layer 31 formed on the first surface and a dielectric layer 32 formed on the reflective layer 31, and the dielectric layer 32 is formed of a dielectric material with a refractive index greater than 1.8.

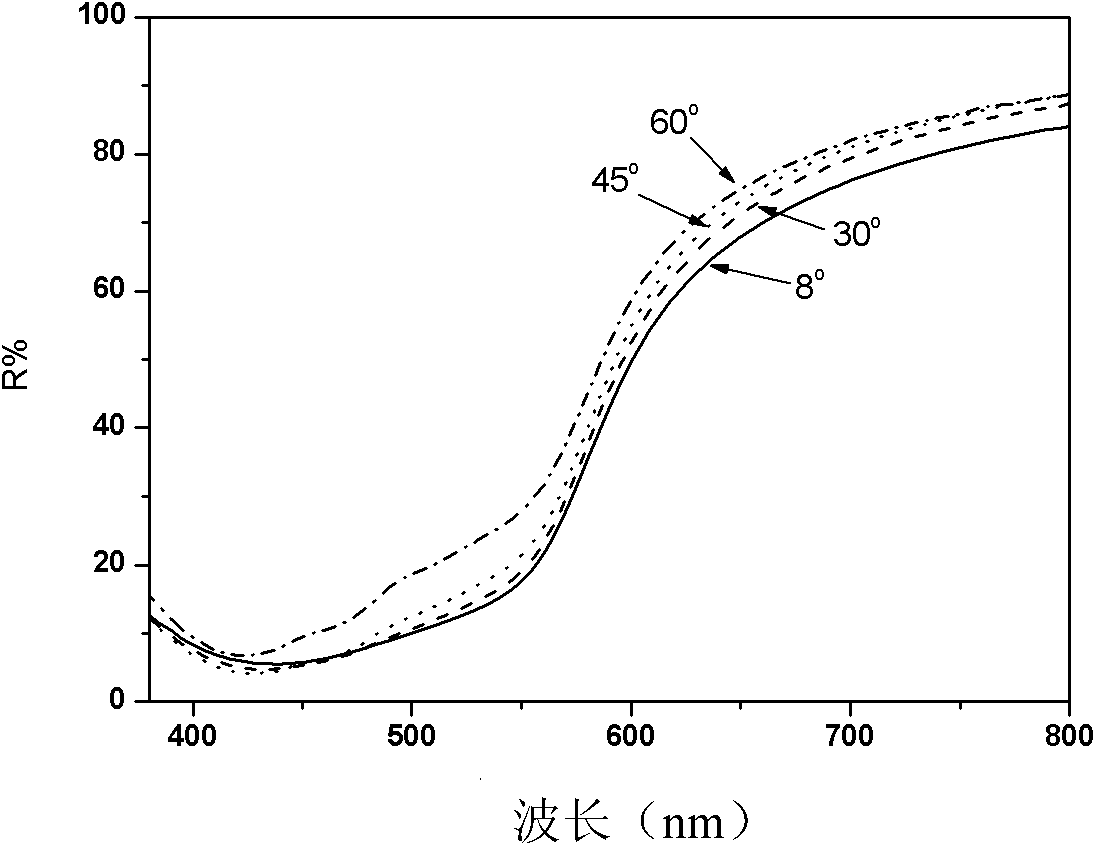

[0022] according to figure 1 In the optical anti-counterfeiting element of the embodiment shown, when the first surface of the substrate 20 is a flat surface, the color of the first coating layer 30 will vary with the material and thickness of the reflective layer ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com