Method for printing stereo concave-convex patterns and product acquired by method

A concave-convex pattern and three-dimensional technology, applied in the field of a method and its obtained products, can solve the problems of inability to form concave-convex patterns, short service life, poor reproducibility, etc., meet aesthetic and decorative requirements, and realize miniaturization and The effect of complexity and low printing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

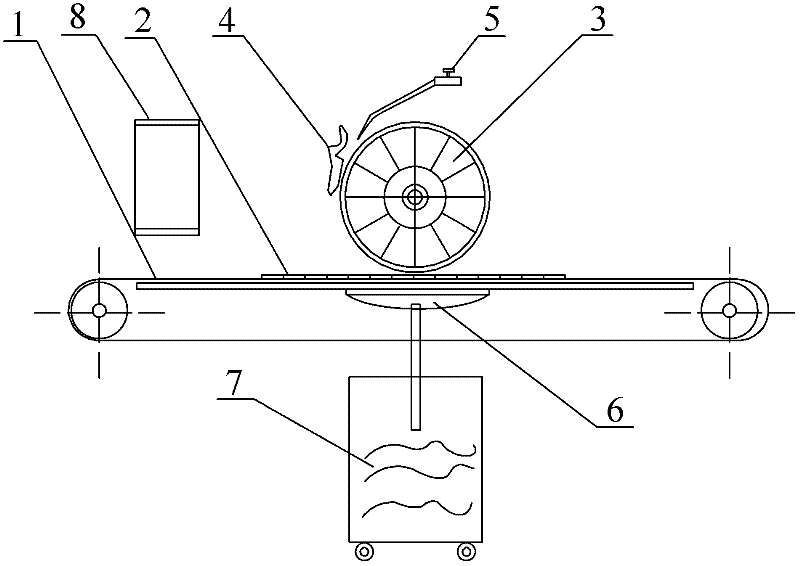

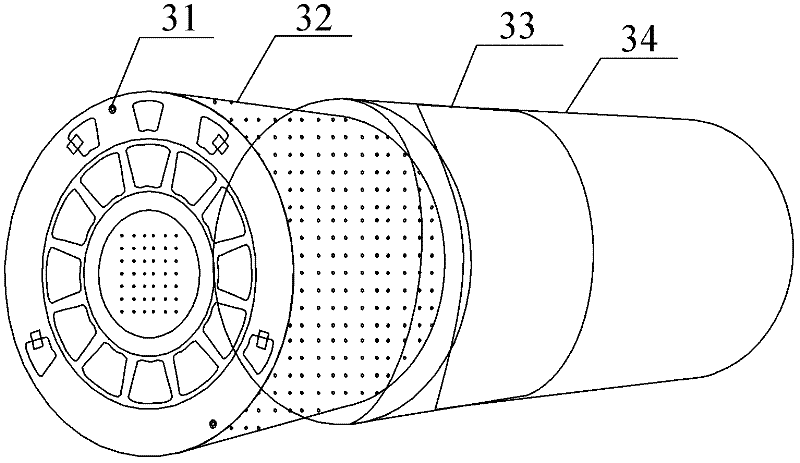

Method used

Image

Examples

Embodiment 1

[0029] After cutting the PVC base material to an appropriate size according to requirements, it is coated and processed. The specific process steps are:

[0030] a) Single-color cartoon pattern printing, using gravure printing equipment;

[0031] b) Use infrared drying at 60°C for 20 minutes;

[0032] c) three-dimensional layer printing of cartoon patterns, using the above-mentioned printing process of the present invention, the maximum film thickness is 2mm;

[0033] d) UV drying, using a three mercury lamp ultraviolet drying, 0.315J / cm 2 、0.362W / cm 2 ;

[0034] e) Apply the primer by spraying, with a film thickness of 20 μm;

[0035] f) Use 6 meters long infrared drying, temperature 60 ℃, 20 minutes;

[0036] g) Sanding, using a sanding machine with 600 mesh sandpaper;

[0037] h) Coating matting topcoat, using spray coating, with a film thickness of 10 μm;

[0038]i) drying in a drying room at a temperature of 80° C. for 60 minutes to obtain a PVC board printed with ...

Embodiment 2

[0040] After the glass substrate is cut to an appropriate size according to requirements, it is coated and processed. The specific process steps are:

[0041] a) Coating the interface paint, using spray coating, with a film thickness of 10 μm;

[0042] b) Use infrared drying at 60°C for 20 minutes;

[0043] c) trademark three-dimensional layer printing, using the above-mentioned printing process described in the present invention, the maximum film thickness is 3mm;

[0044] d) UV drying, using a three mercury lamp ultraviolet drying, 0.315J / cm 2 、0.362W / cm 2 ;

[0045] e) For sanding, use a sanding machine with 1000 mesh sandpaper;

[0046] f) High-gloss finish paint, using spraying, with a film thickness of 10 μm;

[0047] g) drying in a drying room at a temperature of 80° C. for 3 hours to obtain a glass plate printed with a three-dimensional trademark pattern with a raised thickness of 3 mm.

Embodiment 3

[0049] After the aluminum-plastic substrate is cut to an appropriate size according to requirements, it is coated and processed. The specific process steps are:

[0050] a) pickling treatment;

[0051] b) Coating the interface paint, using spray coating, with a film thickness of 10 μm;

[0052] c) drying with infrared rays at a temperature of 60°C for 20 minutes;

[0053] d) The first layer of two-color automobile pattern printing is printed with two-color offset printing equipment;

[0054] e) drying with infrared rays at a temperature of 60°C for 20 minutes;

[0055] f) The second layer of two-color car pattern printing is printed with two-color offset printing equipment;

[0056] g) drying by infrared rays at a temperature of 60°C for 20 minutes;

[0057] h) Three-dimensional layer printing of automobile patterns, using the above-mentioned printing process described in the present invention, with a maximum film thickness of 2.5mm;

[0058] i) UV drying, using a three-m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com