Preparation method of mesoporous LTA zeolite

A mesoporous and zeolite technology, applied in the field of preparation of mesoporous LTA zeolite, can solve the problems of excessively wide mesopore pore size distribution, large mesopore pore size, poor acid strength and hydrothermal stability, etc. Simple operation and low cost of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

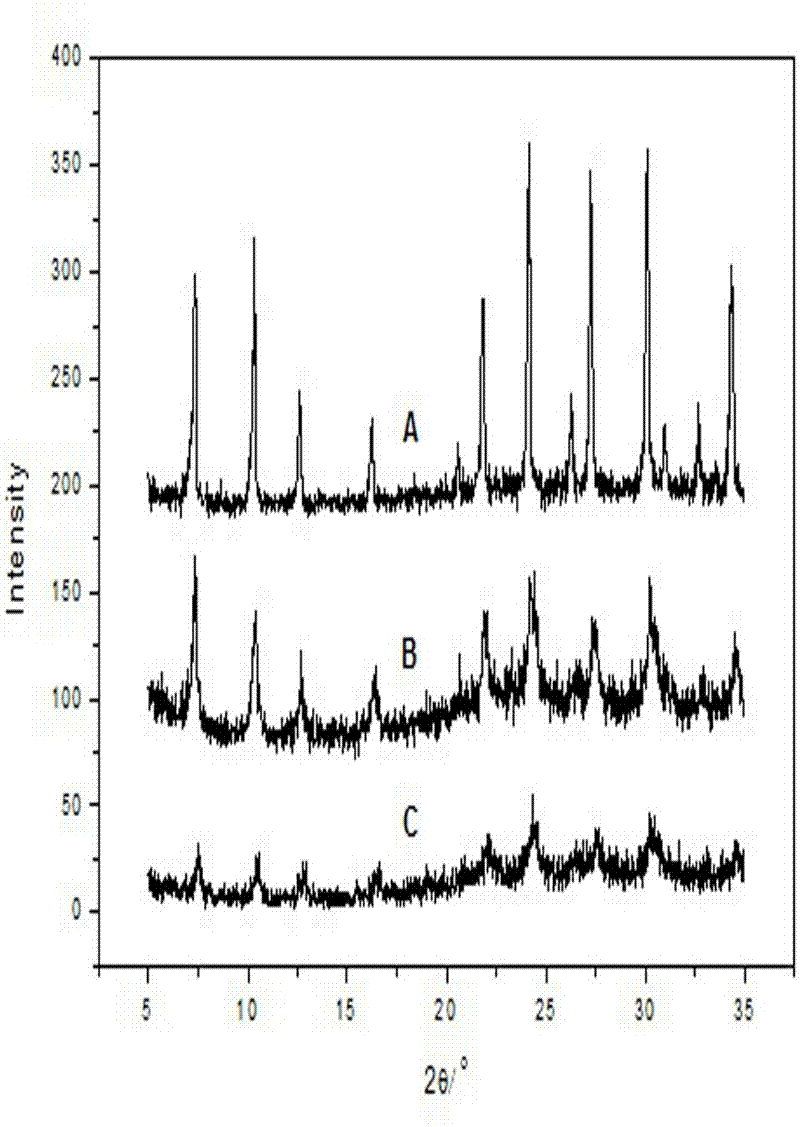

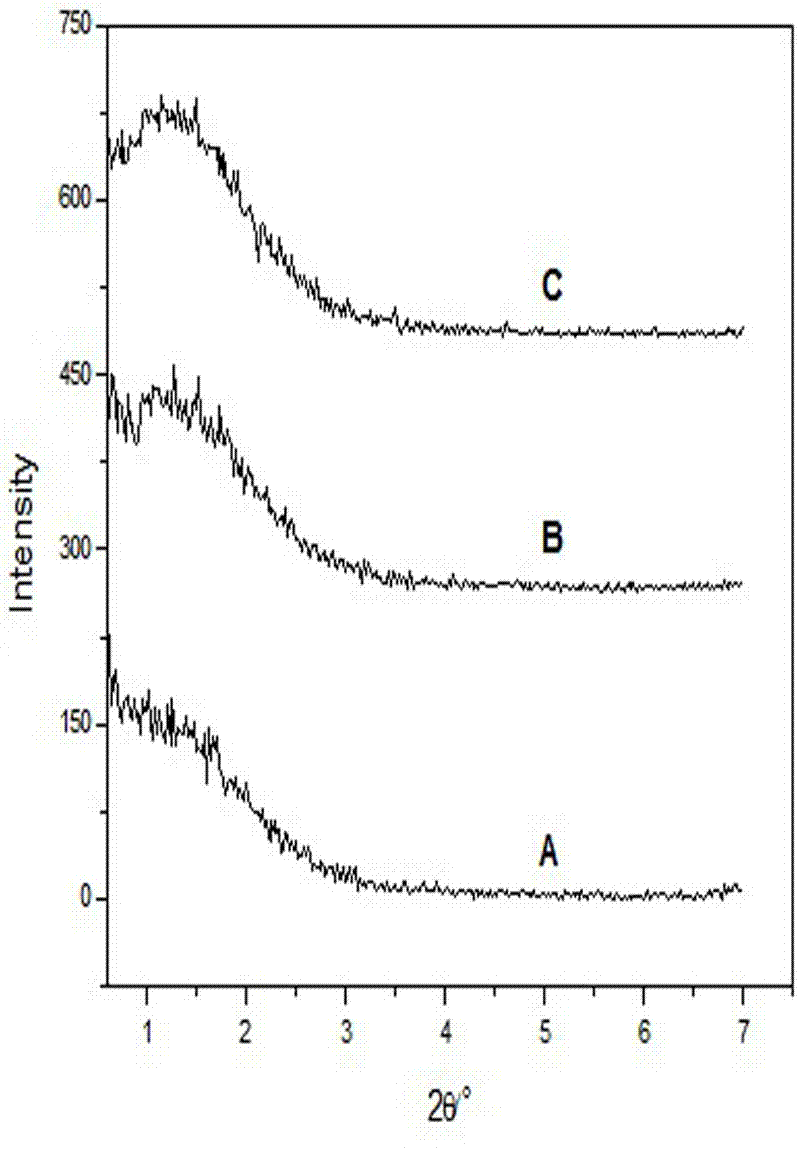

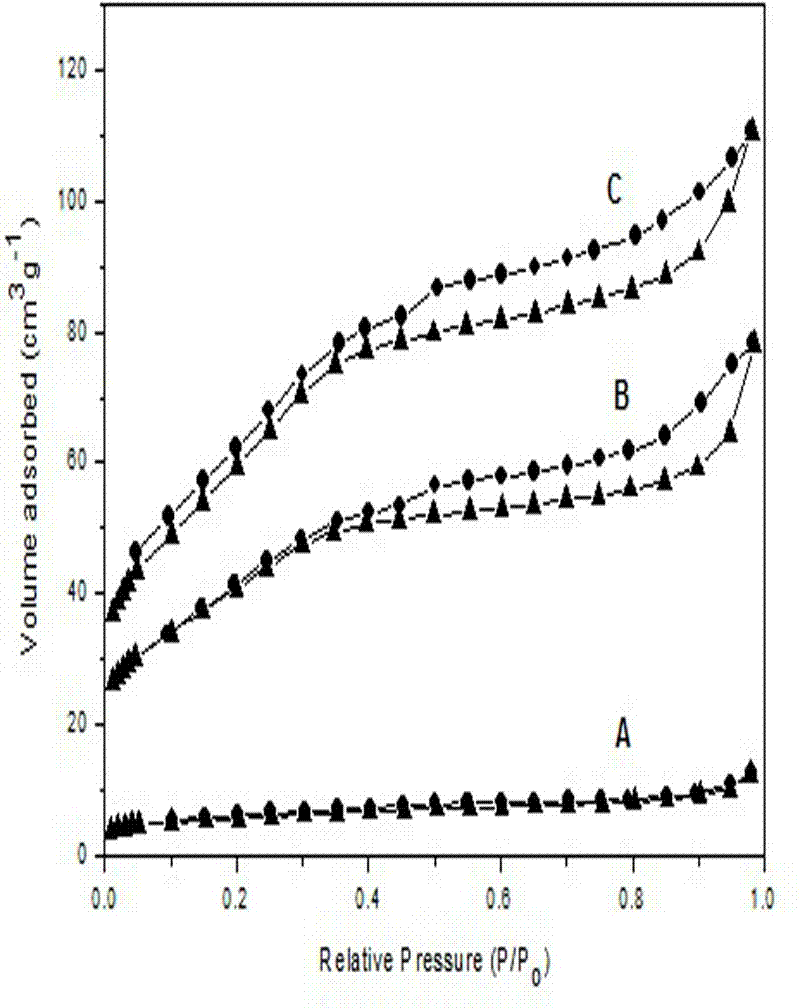

Embodiment 1

[0024] Prepare bridged silsesquioxane (structural formula shown in formula I) by reacting 3-(2,3-glycidoxy)propyltrimethoxysilane and 3-aminopropylmethyldimethoxysilane; Weigh 0.750g of sodium silicate and dissolve it in 4ml of deionized water. At 35°C, take 0.103g of bridged silsesquioxane and add it dropwise to the above sodium silicate solution, and stir well until the solution is clear. Weigh 0.369g of sodium metaaluminate and dissolve it in 4ml of deionized water, then slowly add the above mixed liquid into the sodium metaaluminate solution dropwise, stir at 35°C for 30min, the molar composition of the reaction solution is: 2.173 Na 2 O : Al 2 o 3 : 1.173 SiO 2 : 0.0720 Bridged silsesquioxane: 208 H 2 O. The reaction solution was transferred to a stainless steel reaction kettle, crystallized at 100°C for 120 hours, cooled, washed with a large amount of ionized water until neutral, dried at 100°C for 2 hours, then placed in a muffle furnace, and roasted in an air atm...

Embodiment 2

[0029] Prepare bridged silsesquioxane by reacting 3-(2,3-glycidoxy)propyltrimethoxysilane and 3-aminopropylmethyldimethoxysilane (the structural formula is shown in formula II); Weigh 0.750g of sodium silicate and dissolve it in 4ml of deionized water. At 35°C, take 0.184g of bridged silsesquioxane and add it dropwise to the above sodium silicate solution, and stir well until the solution is clear. Weigh 0.369g of sodium metaaluminate and dissolve it in 4ml of deionized water, then slowly add the above mixed liquid into the sodium metaaluminate solution dropwise, stir at 35°C for 30min, the molar composition of the reaction solution is: 2.173 Na 2 O : Al 2 o 3 : 1.173 SiO 2 : 0.129 Bridged silsesquioxane: 208 H 2 O. The reaction solution was transferred to a stainless steel reaction kettle, crystallized at 100°C for 168 hours, cooled, washed with a large amount of ionized water until neutral, dried at 100°C for 2 hours, then placed in a muffle furnace, and roasted in an ...

Embodiment 3

[0035] Prepare bridged silsesquioxane by reacting 3-(2,3-glycidoxy)propyltrimethoxysilane and 3-aminopropylmethyldimethoxysilane (the structural formula is shown in formula III); Weigh 0.750g of sodium silicate and dissolve it in 4ml of deionized water. At 35°C, take 0.220g of bridged silsesquioxane and add it dropwise to the above sodium silicate solution, and stir well until the solution is clear. Weigh 0.369g of sodium metaaluminate and dissolve it in 4ml of deionized water, then slowly add the above mixed liquid into the sodium metaaluminate solution dropwise, stir at 35°C for 30min, the molar composition of the reaction solution is: 2.173 Na 2 O : Al 2 o 3 : 1.173 SiO 2 : 0.154 Bridged silsesquioxane: 208 H 2 O. The reaction solution was transferred to a stainless steel reaction kettle, crystallized at 100°C for 192 hours, cooled, washed with a large amount of ionized water until neutral, dried at 100°C for 2 hours, then placed in a muffle furnace, and roasted in an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com