Manufacturing method of ceramic product with crack glaze

A production method and technology of cracked glaze, applied in the field of ceramics, can solve problems such as difficulty in innovation, difficulty in adapting to consumers' innovation and change, and inability to break through the design level.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

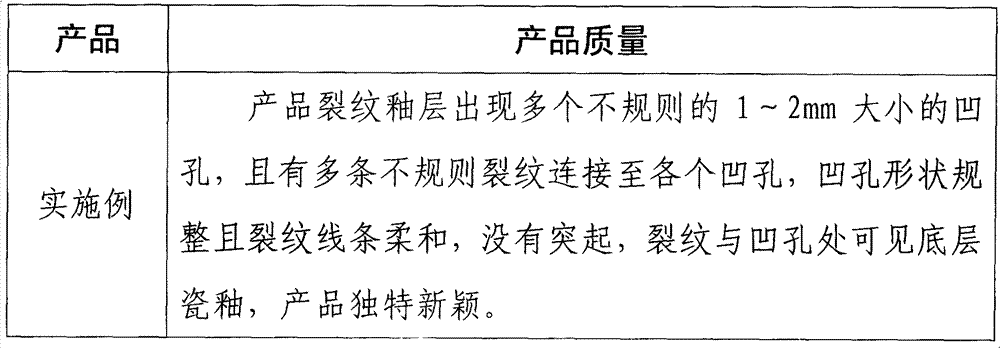

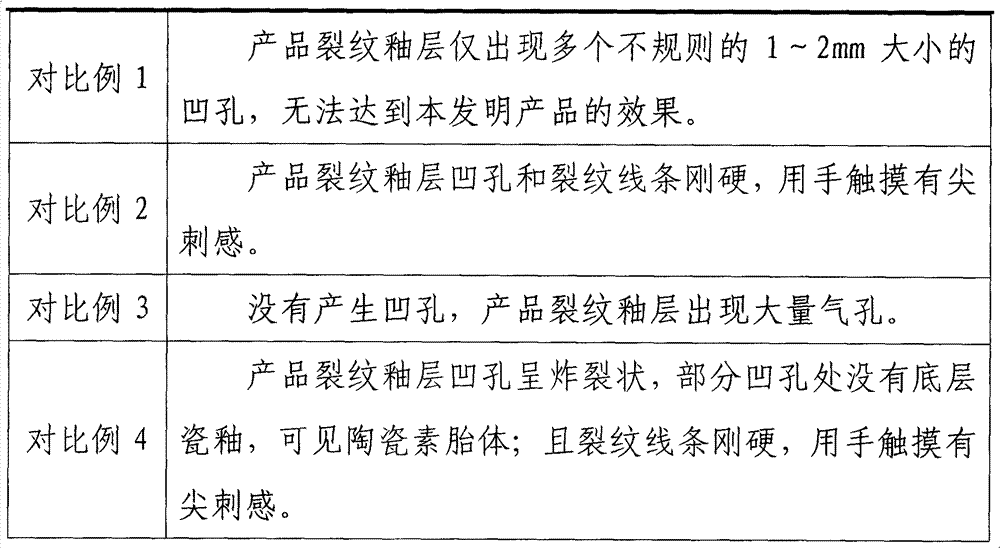

Examples

Embodiment

[0014] Embodiment: Take 44 parts by weight of feldspar, 8 parts by weight of talc, 38 parts by weight of kaolin, and 24 parts by weight of quartz and put them into a ball mill, then add 34.2 parts by weight of clear water to ball mill and pass through a 240-mesh sieve to make the bottom enamel for later use;

[0015] Take 14 parts by weight of diatomite, 44 parts by weight of feldspar, 18 parts by weight of calcium carbonate, 32 parts by weight of talc, 4 parts by weight of kaolin, and 1.5 parts by weight of sawdust with a particle diameter of 1.5 mm, and put them into a ball mill, and then add 34.05 parts by weight of clear water to carry out Ball mill through 240 mesh sieve to make crackle enamel for later use;

[0016] According to the traditional production method of ceramic products, the ceramic matrix is produced;

[0017] Spray the above-mentioned spare bottom enamel evenly on the surface of the ceramic body, the thickness of the glaze layer is 2mm, and dry it for 4 h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com