Repair reinforcing structure of steel bridge deck and repair reinforcing method of repair reinforcing structure

A technology for steel bridge decks and reinforcing structures, applied in bridge maintenance, bridges, bridge parts, etc., can solve the problems affecting the safety and long-term service life of bridges, the threat of bridge design service life, and the inability to change the stress state of the structure. Achieve the effect of low comprehensive cost, simple and fast construction, and small social traffic impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

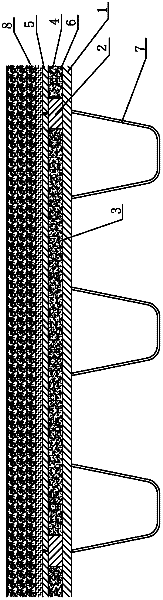

[0024] The deck of a suspension steel bridge is 18 meters wide and 900 meters long, with a designed service life of 100 years. The steel plate thickness of the bridge deck is 10-12 mm. figure 1 shown). Only 12 years of heavy-duty traffic operation, there are many through-cracks several meters long in the U-shaped stiffeners. Rainwater enters the inside of the box girder under the steel plate of the bridge deck through the cracks, resulting in undue corrosion, which affects the safety of the bridge and its operation. .

[0025] The repair and reinforcement structure of the steel bridge deck is as follows: figure 1 As shown, including the bridge deck steel plate 1, the upper surface of the bridge deck steel plate 1 is welded with multiple longitudinal steel ribs 2 and multiple transverse steel ribs 2 (in the illustration, 2 is used to uniforml...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com