Energy dissipating element of grouting sleeve

A technology of energy-dissipating components and bushings, which can be used in building components and anti-shock, etc., can solve the problems of expansion cement ring wear, increase friction coefficient, performance degradation, etc., and achieve the effect of saving steel, maintaining stable performance, and easy on-site installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

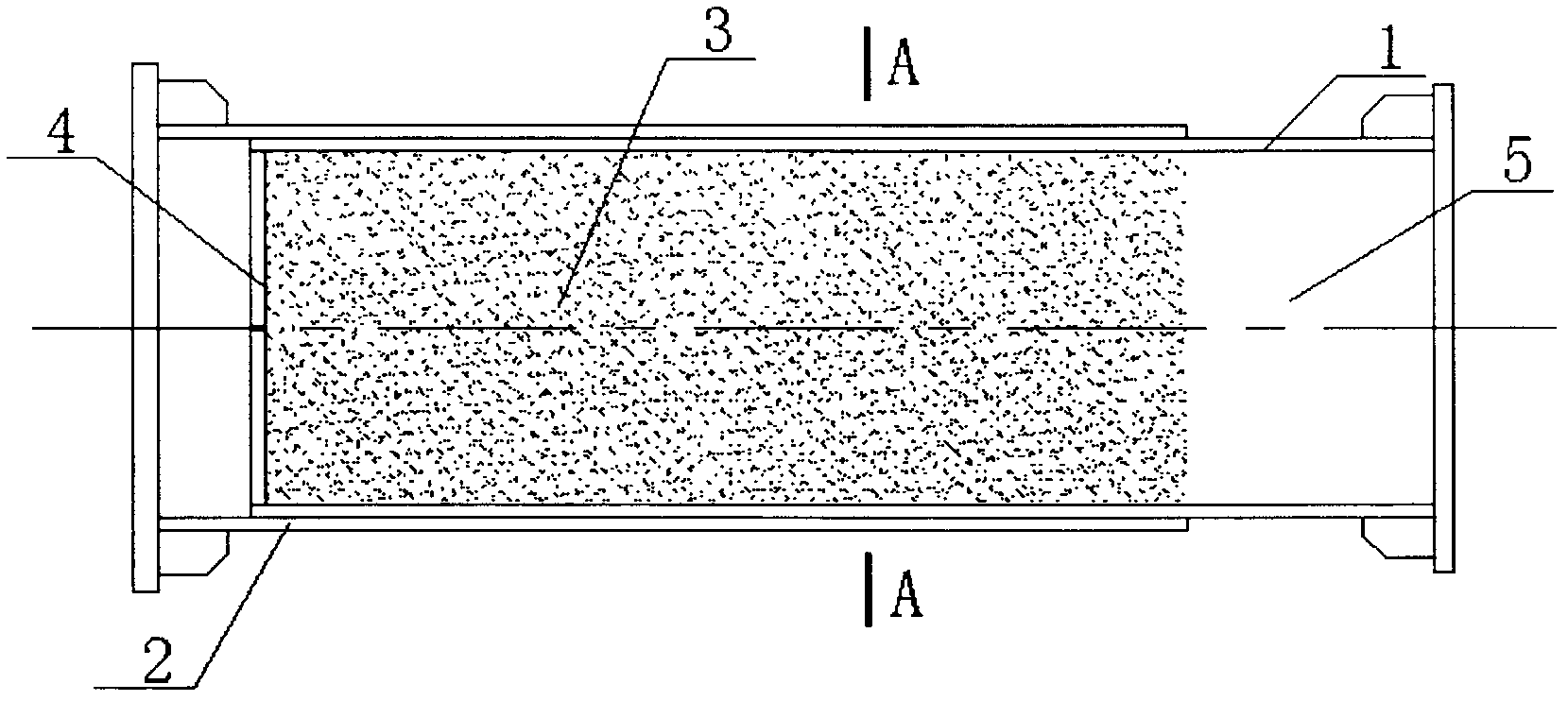

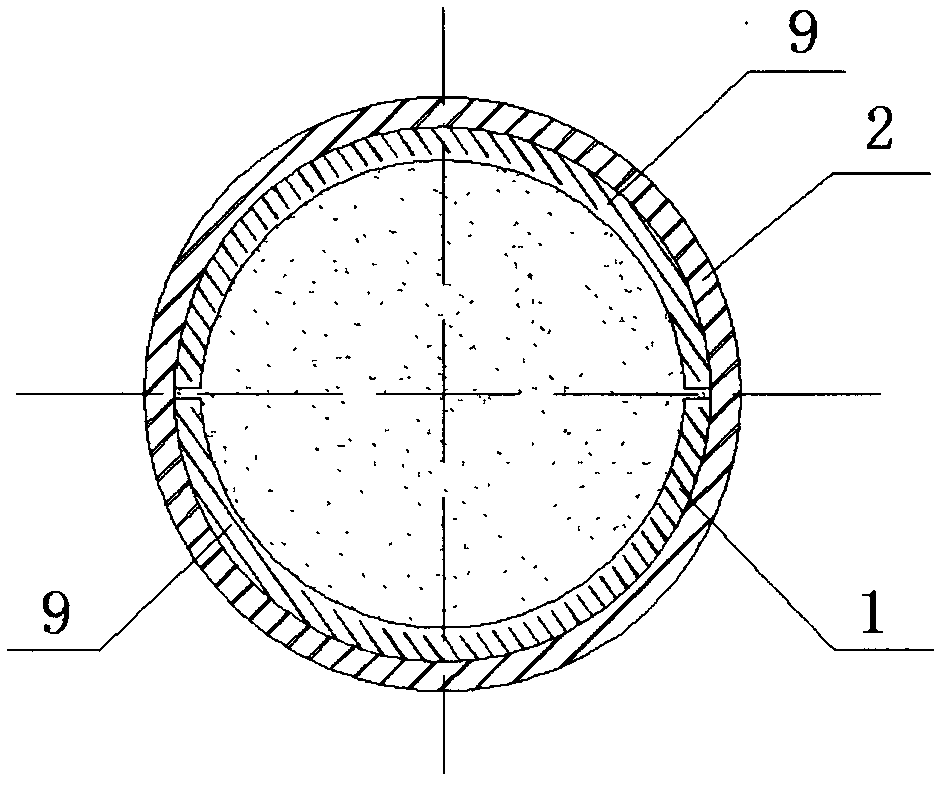

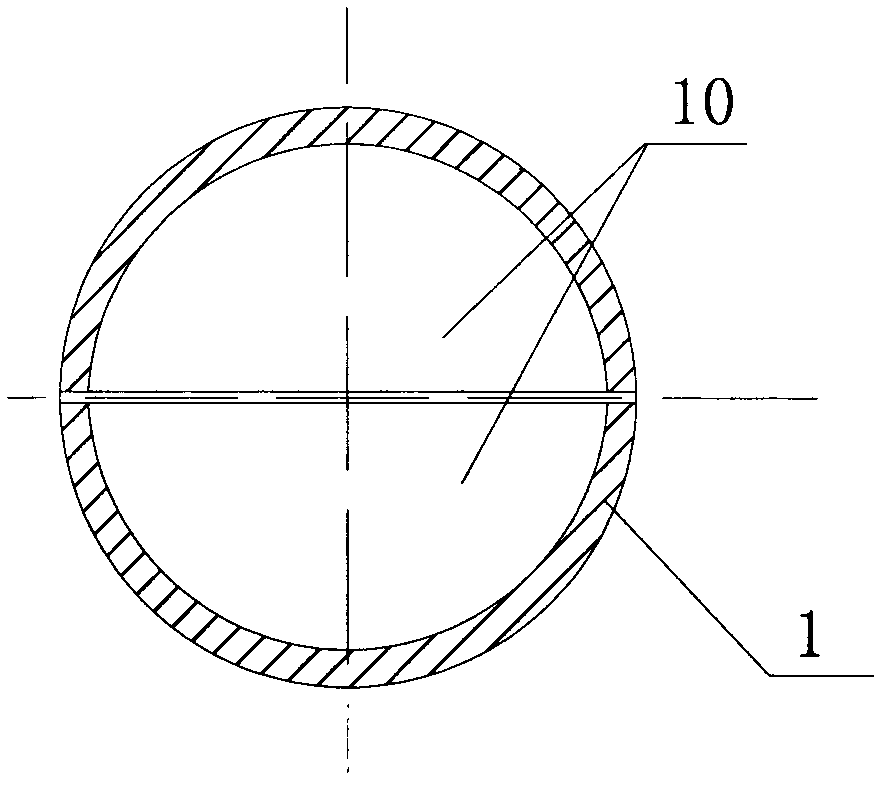

[0017] Such as figure 1 As shown, the outer wall of the inner tube 1 is attached to the inner wall of the outer tube 2 and inserted into the outer tube to form an inner tube insertion section 3 and an inner tube exposed section 5. The cover plate 4 is located at the inner end of the inner tube insertion section to cover the inner tube. 1 end. figure 2 for figure 1 The A-A profile, such as figure 2 As shown, the inner tube is spliced by two tube walls 9 with a semicircular section. At the same time, if image 3 As shown, the cover plate is spliced by two semicircular cover plate segmentation blocks 10, and the arc edge of each cover plate segmentation block 10 is respectively connected to one of the two pipe walls, and the cover plate segmentation block 10 The diameter sides are spliced with each other to form the whole cover ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com