Formation method of Mg/Sn/W composite oxide catalyst

A composite oxide and molding method technology, which is applied in the molding field of Mg/Sn/W composite oxide catalyst, can solve the problem that the catalyst is difficult to recycle, and achieve the effect of easy separation and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

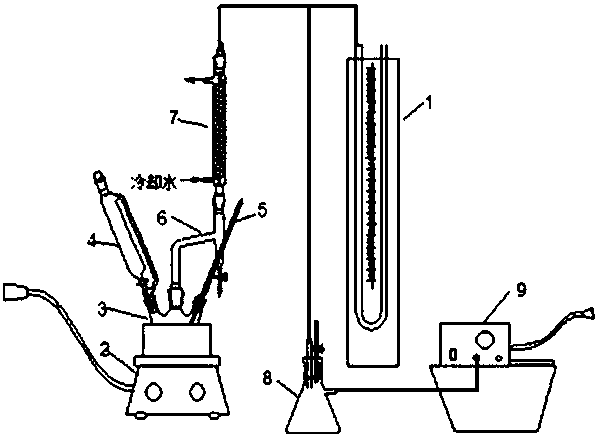

Image

Examples

Embodiment 1

[0023] The steps of the molding method of the Mg / Sn / W composite oxide catalyst of this embodiment are as follows:

[0024] (1) Mix 30g Mg / Sn / W composite oxide catalyst powder, 0.9g activated carbon, 0.6g sesame powder, and 3g pseudo-boehmite first, and then add 0.9g nitric acid aqueous solution to obtain a wet mass ;

[0025] (2) Put the wet mass into the extruder and extrude it into a strip with a diameter of about 9mm and cut it to a length of about 2cm to obtain a shaped catalyst;

[0026] (3) Dry the formed catalyst in a drying oven at 80°C for 16 hours;

[0027] (4) Put the dried strip catalyst into a muffle furnace for high-temperature roasting. The roasting process adopts a programmed temperature rise at a heating rate of 1~3°C / min, and it is roasted at 550°C for 3 hours.

Embodiment 2

[0029] The steps of the molding method of the Mg / Sn / W composite oxide catalyst of this embodiment are as follows:

[0030] (1) Mix 30g of Mg / Sn / W composite oxide catalyst powder and 2.4g of activated carbon first; then add 3g of sesame powder, 12g of 25% silica sol solution, and add an aqueous solution containing 3.3g of nitric acid to obtain a wet mass;

[0031] (2) Put the wet mass into the extruder and extrude it into a strip with a diameter of about 9mm and cut it to a length of about 2cm to obtain a shaped catalyst;

[0032] (3) Dry the formed catalyst in a drying oven at 120°C for 12 hours;

[0033] (4) Put the dried strip catalyst into a muffle furnace for high-temperature roasting. The roasting process uses a programmed temperature rise at a rate of 1~3°C / min, and it is roasted at 550°C for 1 hour.

Embodiment 3

[0035] The steps of the molding method of the Mg / Sn / W composite oxide catalyst of this embodiment are as follows:

[0036] (1) Mix 30g Mg / Sn / W composite oxide catalyst powder and 1.5g activated carbon first; then add 3g sesame powder, 15g 30% aluminum sol solution, and add 1.5g nitric acid aqueous solution to obtain a wet mass;

[0037] (2) Put the wet mass into the extruder and extrude it into a strip with a diameter of about 9mm and cut it to a length of about 2cm to obtain a shaped catalyst;

[0038] (3) Dry the formed catalyst in a drying oven at 100°C for 24 hours;

[0039] (4) Put the dried strip catalyst into a muffle furnace for high-temperature roasting. The roasting process uses a programmed temperature rise at a rate of 1~3°C / min, and it is roasted at 500°C for 2h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com