Valve apparatus and absorption refrigerator using the same

A technology of absorption refrigerator and valve device, which is applied in the direction of valve device, adsorption machine, valve operation/release device, etc. It can solve the problems of high iron content and inability to maintain performance, so as to prevent valve device from locking, Maintain performance stably for a long time and solve the effect of poor valve operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

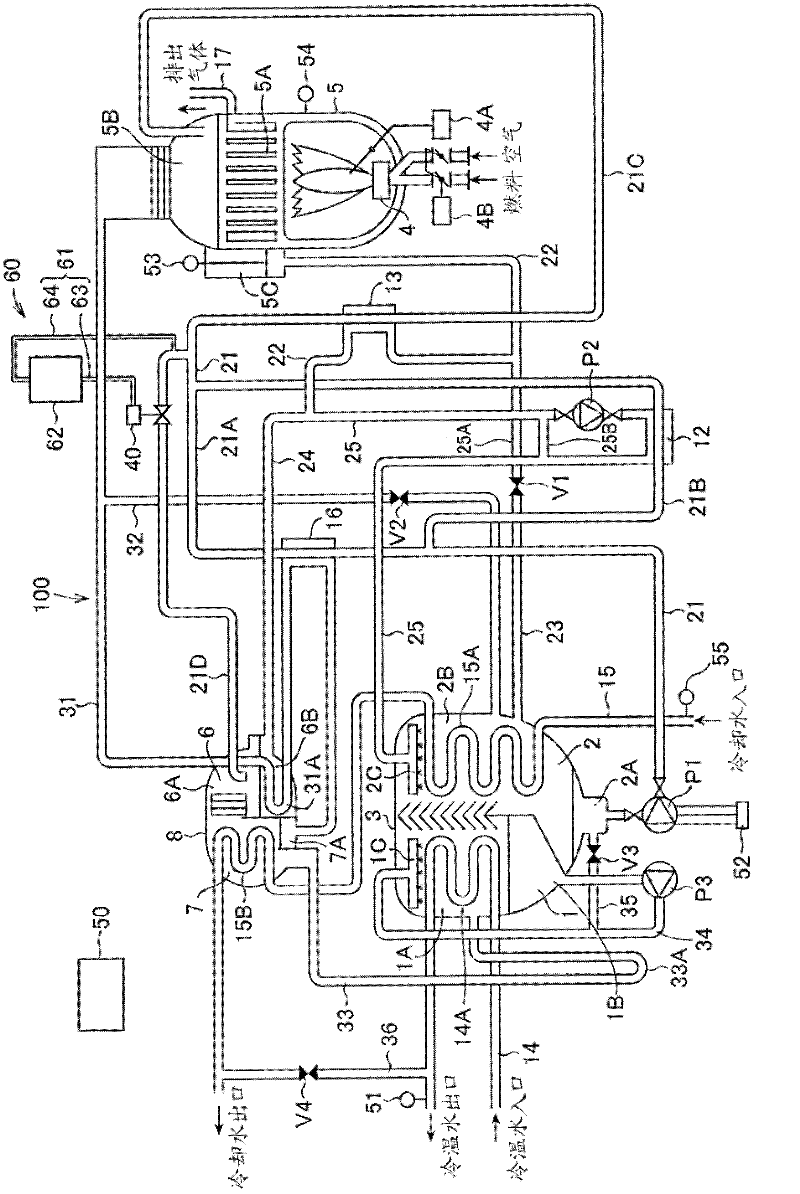

[0064] figure 1 It is a schematic configuration diagram of the absorption refrigerator of the first embodiment.

[0065] The absorption refrigerator 100 is a double-effect absorption refrigerator using water as a cooling medium and a lithium bromide (LiBr) aqueous solution as an absorbing liquid.

[0066] Such as figure 1 As shown, the absorption refrigerator 100 includes: an evaporator 1, an absorber 2 arranged in parallel with the evaporator 1, an evaporator-absorber cylinder 3 for accommodating the evaporator 1 and the absorber 2, and a gas burner 4 The high-temperature regenerator 5, the low-temperature regenerator 6, the condenser 7 arranged in parallel with the low-temperature regenerator 6, the low-temperature regenerator condenser cylinder 8 for accommodating the low-temperature regenerator 6 and the condenser 7, the low-temperature heat exchanger 12, the high-temperature regenerator Heat exchanger 13, cooling medium release heat recovery device 16, thin absorption l...

no. 2 approach

[0108] Next, a second embodiment will be described.

[0109] Figure 6 It is a schematic configuration diagram of the absorption refrigerator 200 of the second embodiment. In addition to replacing the locking prevention mechanism 60 ( figure 1 ) except that the locking prevention mechanism 260 is provided, the absorption refrigerator 200 has the same structure as the absorption refrigerator 100 of the first embodiment. Therefore, in Figure 6 in, right with figure 1 The same parts of the shown absorption refrigerator 100 are assigned the same reference numerals, and description thereof will be omitted.

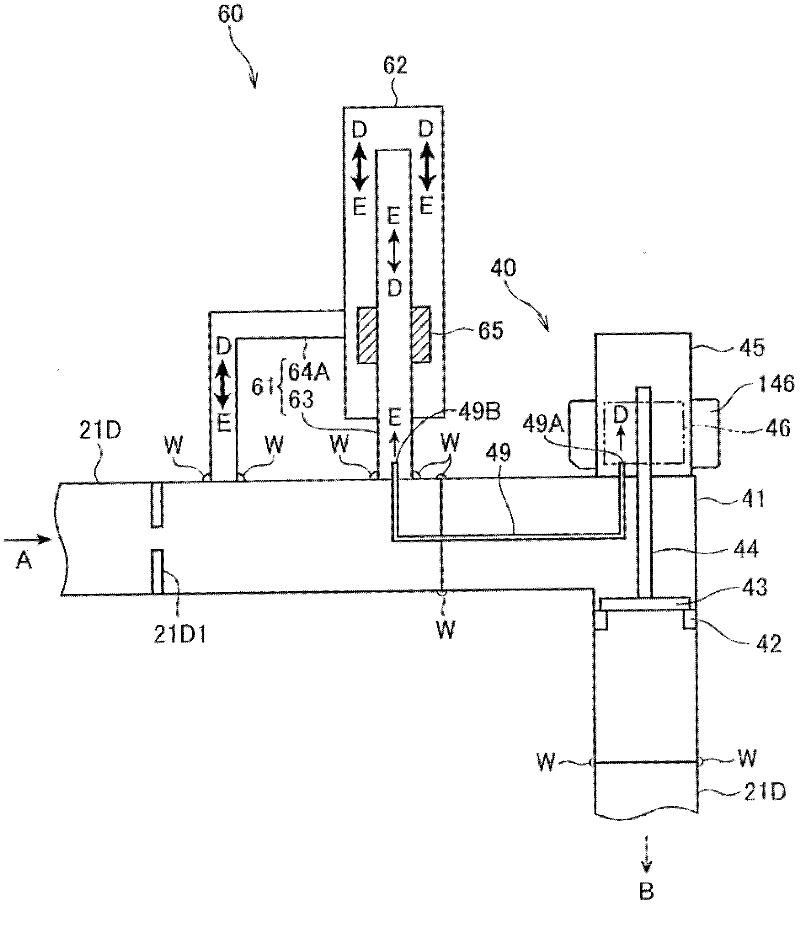

[0110]The lock preventing mechanism 260 has a first supply pipe 261 that supplies the diluted absorbent liquid to the diluted absorbent distribution valve 40 , and a diluted absorbent liquid tank (liquid source) 262 that stores the diluted absorbent fluid. One end of the first supply pipe 261 is welded with the fourth dilute absorption liquid pipe 21D similarly to the firs...

no. 3 approach

[0116] Next, a third embodiment will be described.

[0117] Figure 7 It is a schematic configuration diagram of an absorption refrigerator 300 according to a third embodiment. In addition to replacing the locking prevention mechanism 60 ( figure 1 ) except that the locking prevention mechanism 360 is provided, the absorption refrigerator 300 has the same structure as the absorption refrigerator 100 of the first embodiment. Therefore, in Figure 7 in, right with figure 1 The same parts of the shown absorption refrigerator 100 are assigned the same reference numerals, and description thereof will be omitted.

[0118] The lock preventing mechanism 360 has a first supply pipe 361 for supplying the coolant liquid to the dilute absorption liquid distribution valve 40 , and a solenoid valve 362 provided in the middle of the first supply pipe 361 . One end of the first supply pipe 361 is welded with the fourth dilute absorption liquid pipe 21D similarly to the first supply pipe 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com