High precision absolute encoder

An absolute encoder, high-precision technology, applied in the direction of mitigating unwanted effects, can solve the problems of poor installation and coordination accuracy, complex calculation process that cannot meet high-speed, high-precision miniaturization, and high cost, and achieve wide temperature range Adaptable range, strong dust resistance, high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The high-precision absolute encoder provided by the present invention will be further described below in conjunction with the drawings and preferred embodiments.

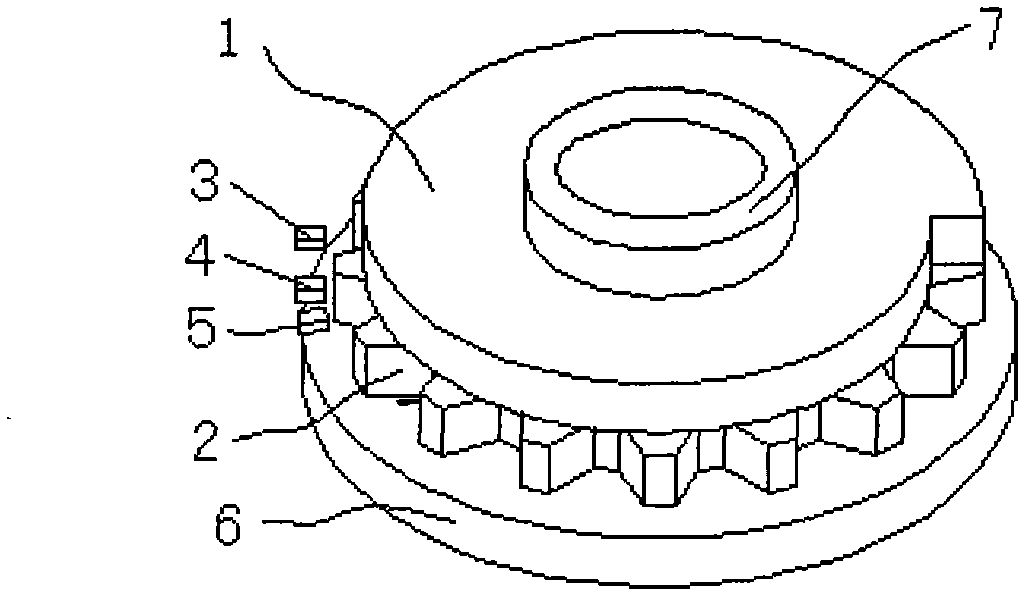

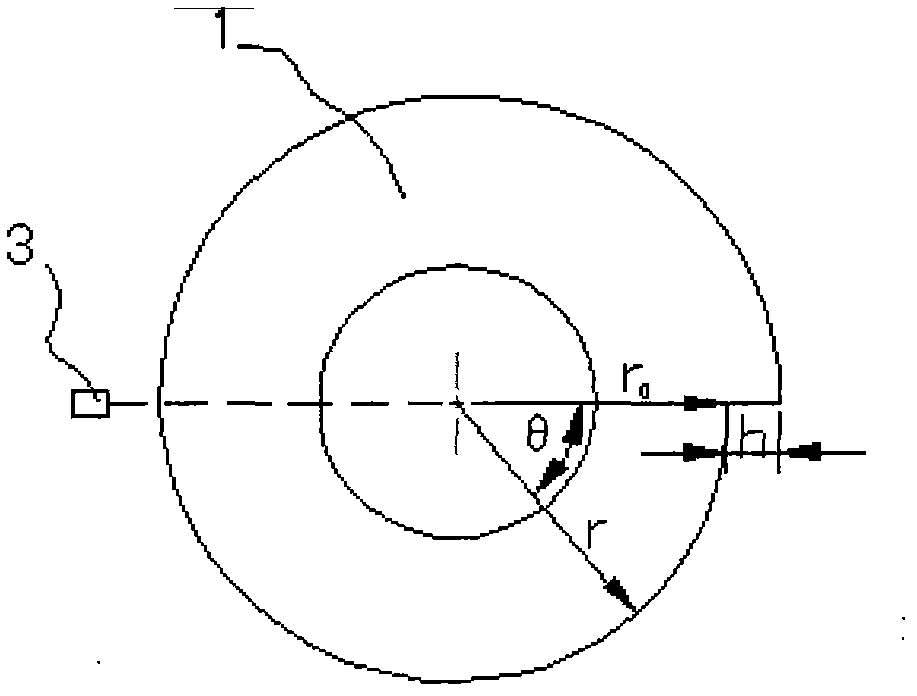

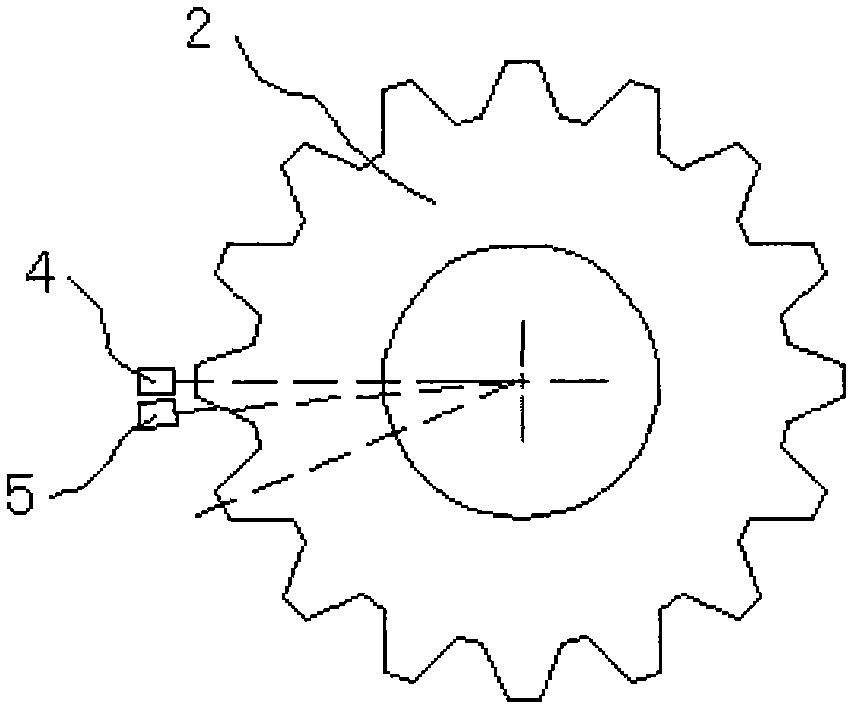

[0018] figure 1 It is a schematic diagram of the internal structure of the high-precision absolute encoder of the present invention. In this embodiment, the wheel whose radius changes with the angle is a wheel whose radius changes linearly with the angle, and the gear is a trapezoidal gear. The encoder mainly includes a wheel 1 used to determine the absolute position of the motor whose radius changes linearly with the angle, a gear 2 used to determine the direction of motor rotation and the precise position of the motor, three position sensors 3, 4, and 5, one for The integrated circuit board 6 for processing the output signal of the sensor, the shaft sleeve 7 and the encoder housing.

[0019] The wheel 1 and the gear 2 whose radius changes linearly with the angle are fixed on the sleeve 7 and can rotate together ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com