Method for predicting relaxation life of spiral spring on basis of stress relaxation theory of temperature accelerating material

A helical spring and stress relaxation technology, which is applied in the field of predicting the relaxation life of helical springs based on the theory of temperature-accelerated material stress relaxation, can solve the problems of large artificial errors in measurement data, cumbersome procedures, and long experimental periods, so as to improve efficiency and predict accuracy High, reduce the effect of test cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

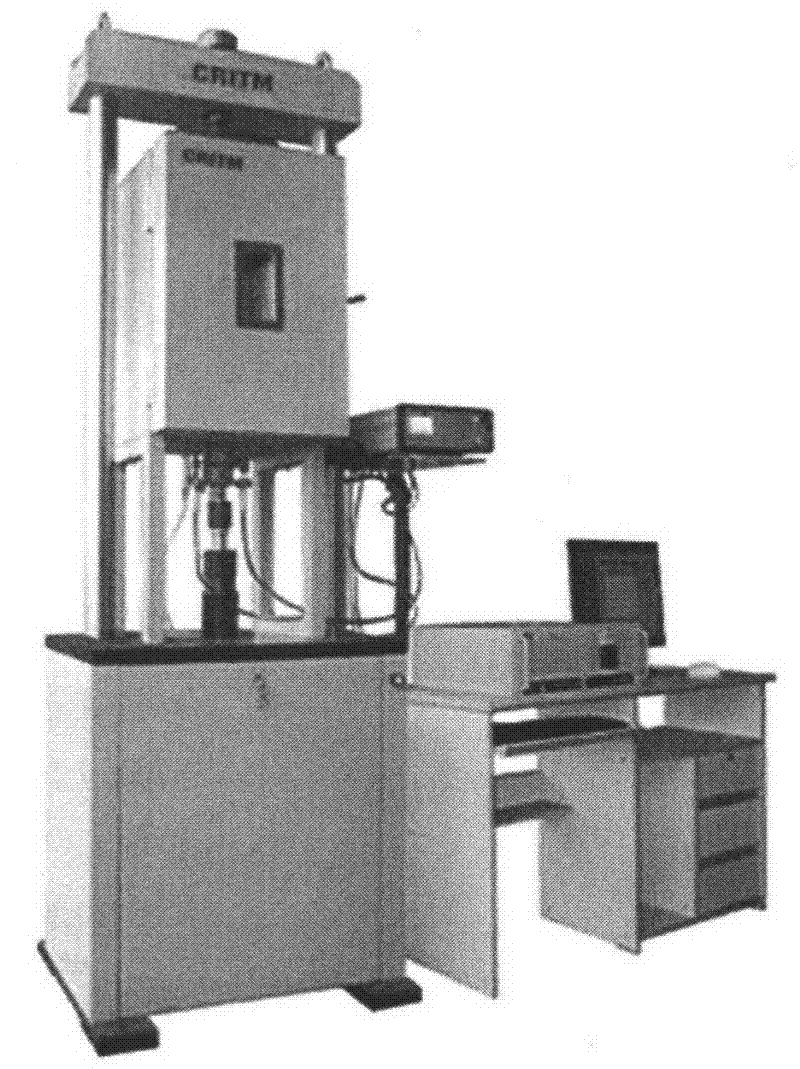

[0039] In this embodiment, a helical compression spring wound with 60Si2Mn oil-quenched and tempered steel wire is used for testing, and the basic parameters of the spring are d=10mm, D=40mm, t=15mm, H 0 = 66mm.

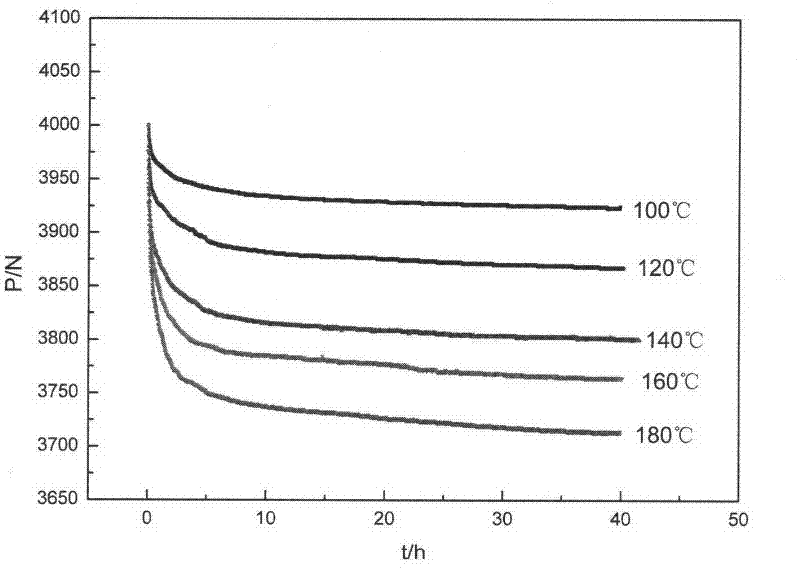

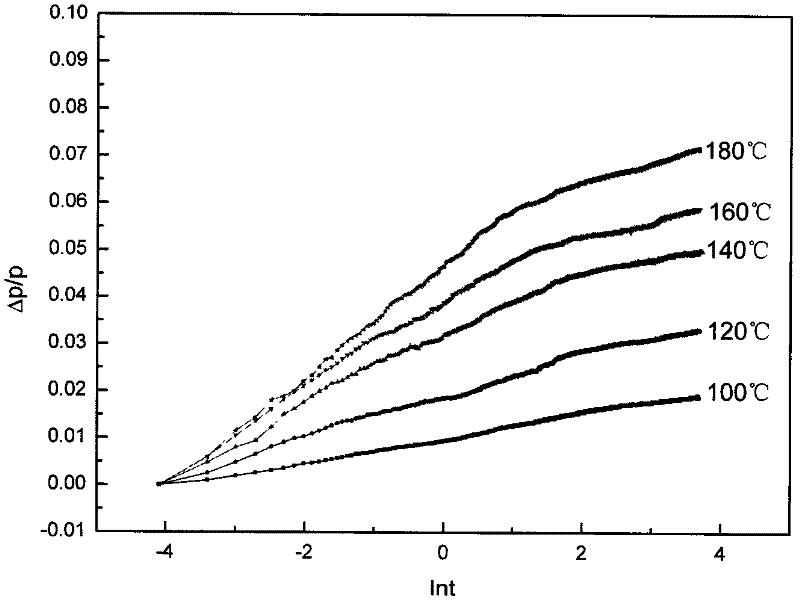

[0040] Before the test, preheat the equipment for 3 hours to eliminate the influence of the thermal expansion of the fixture on the test. Five temperature points of 100°C, 120°C, 140°C, 160°C and 180°C were selected as the accelerated stress relaxation test temperature. Because the wire diameter of this helical spring is relatively thick, preheat the spring for 30 minutes before loading. After preheating, compress the spring at a compression speed of 2.7mm / min until the storage height H of the spring in actual use 1 = 51 mm. The stress relaxation time is 40h. The data points in the relaxation test are collected one minute, and this process is completed autonomously by the computer system.

[0041] At five temperature points of 100°C, 120°C, 140°C, 160°C and 180°...

Embodiment 2

[0052] The present embodiment adopts the helical compression spring of 65Mn oil quenching and tempering steel wire winding to carry out the test, and the basic parameters of the spring are d=6mm, D=25mm, t=8mm, H 0 =290mm.

[0053] Before the test, preheat the equipment for 3 hours to eliminate the influence of the thermal expansion of the fixture on the test. Five temperature points of 80°C, 100°C, 120°C, 140°C and 160°C were selected as the accelerated stress relaxation test temperature. Since the wire diameter of this coil spring is relatively thin, preheat the spring for 15 minutes before loading. After preheating, compress the spring at a compression speed of 6mm / min until the storage height H of the spring in actual use 1 =230mm. The stress relaxation time is 24h. The data points in the relaxation test are collected one minute, and this process is completed autonomously by the computer system.

[0054] At five temperature points of 80°C, 100°C, 120°C, 140°C and 160°...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com