Piston-type constant-pressure controllable airflow source flow measurement device

A technology for controlling airflow and flow devices, applied in measuring devices, suspension and porous material analysis, scientific instruments, etc., can solve problems such as large fluctuations in measurement results, rapid changes in airflow and pressure in the circuit, rapid changes in flow and pressure, etc. Achieve the effects of improving efficiency and accuracy, fast real-time response, and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention is further described below in conjunction with accompanying drawing:

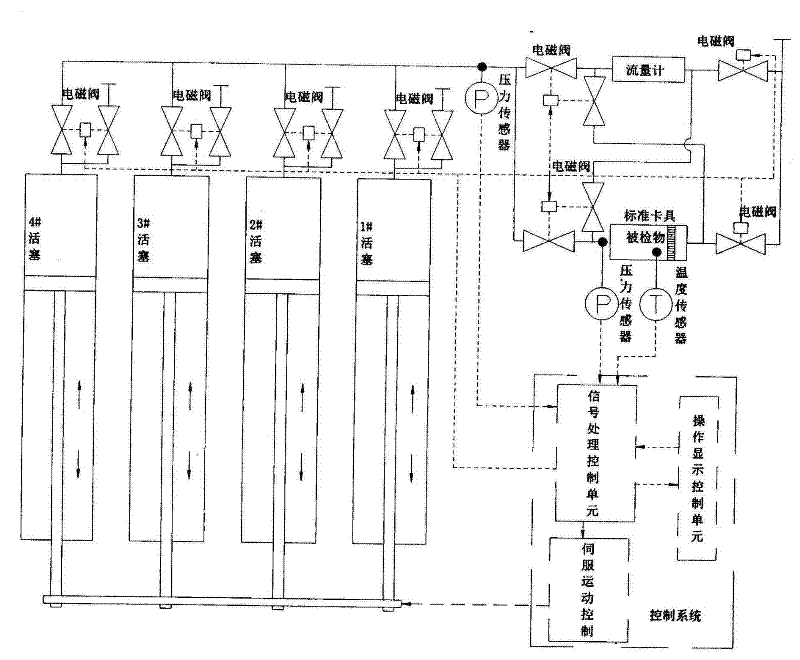

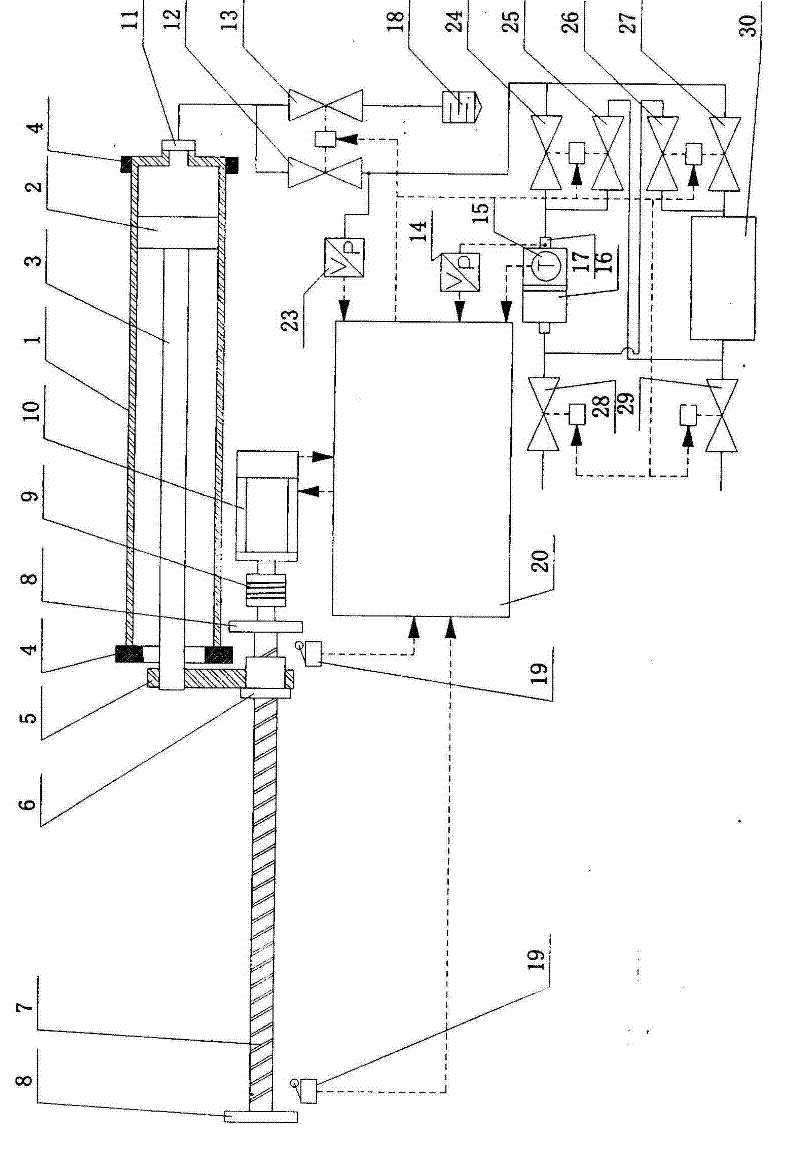

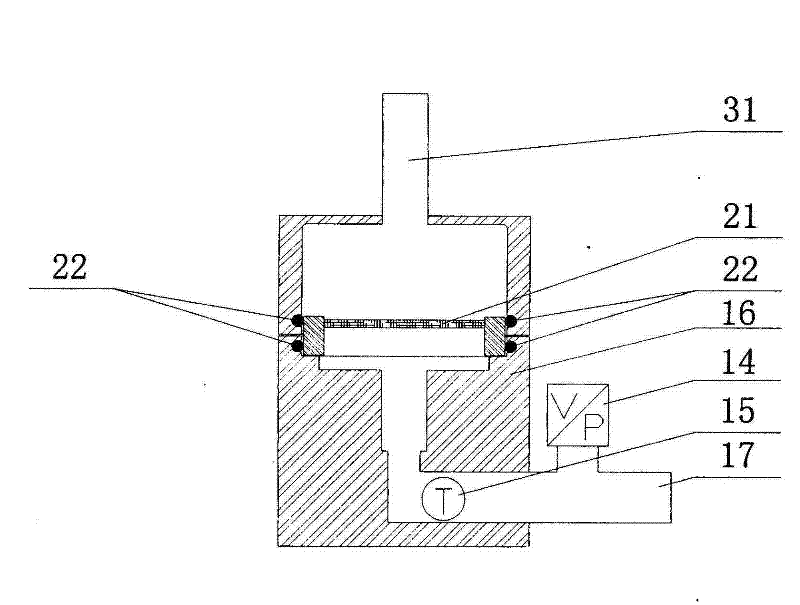

[0019] Such as Figure 1-3 Shown: the piston-type constant pressure controllable airflow source flow measuring device of the present invention includes a linear motion suction system and a measurement and test unit and a controller 20 for controlling the suction system and the measurement and test unit, and the linear motion system consists of Four sets of piston cylinders 1, lead screws 7 connected to four piston rods 3, and a servo motor 10 that drives the leads to rotate; the measurement and testing unit includes a working interface 11 installed at the air outlet at the front end of the piston cylinders. , a working solenoid valve, a measuring solenoid valve, a standard appliance fixture 16, a fixture interface and a flow test unit 30; the rotation of the servo motor 10 and the limit switches in the movement range of the piston rod 3 are all controlled by the controller 20; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com