Hyperspectral-analysis-based copper quality detection method and system

A quality inspection and hyperspectral technology, applied in the field of inspection, can solve the problem that the accuracy of estimation and judgment depends on operating experience and fatigue state, low reliability, and low reliability of test results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] In order to describe the present invention more specifically, the technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

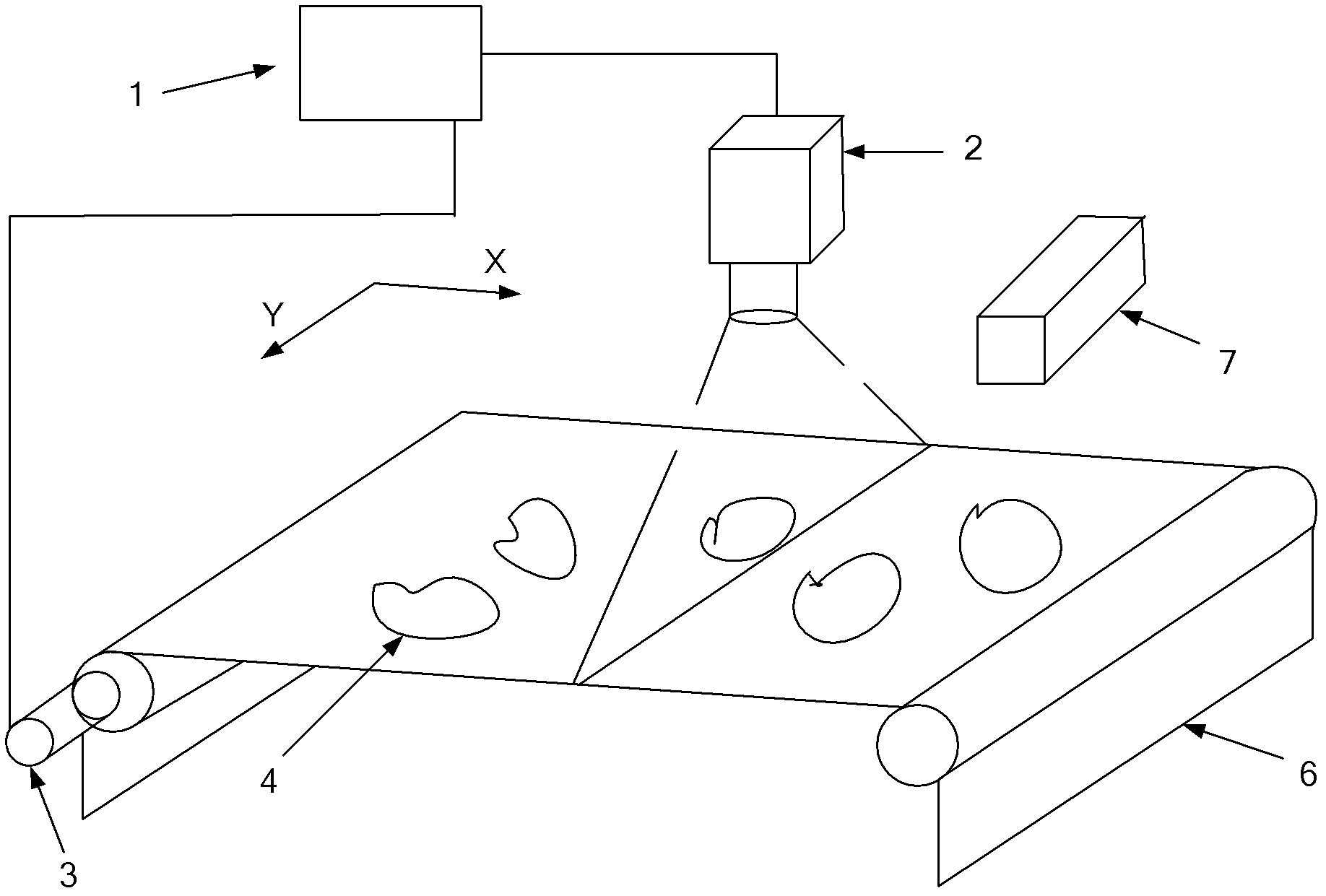

[0057] Such as figure 1 As shown, a copper quality detection system based on hyperspectral analysis includes: an industrial control computer 1 and a hyperspectral imager 2 .

[0058] The object to be measured in this embodiment is the copper material 4 on the conveyor belt 6 of the copper processing production line. 6 The distance of transmission is recorded, and this pulse signal (one pulse corresponds to a unit distance of 1 mm) is transmitted to the industrial control computer 1 by a high-speed pulse data acquisition card; in the present embodiment, the model used by the photoelectric encoder is RVI50N-09BK0A3TN-600, The model used for the high-speed pulse data acquisition card is PXI6220.

[0059] A halogen lamp 7 is fixed above the conveyor belt 6,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com