Travelling device for welding joint radiological inspecting machine

A technology of ray inspection and walking device, which is applied to measuring devices, material analysis using wave/particle radiation, instruments, etc., can solve the problems of safety risks and low precision, reduce the frequency, improve the quality and success rate of filming, The effect of shortening the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

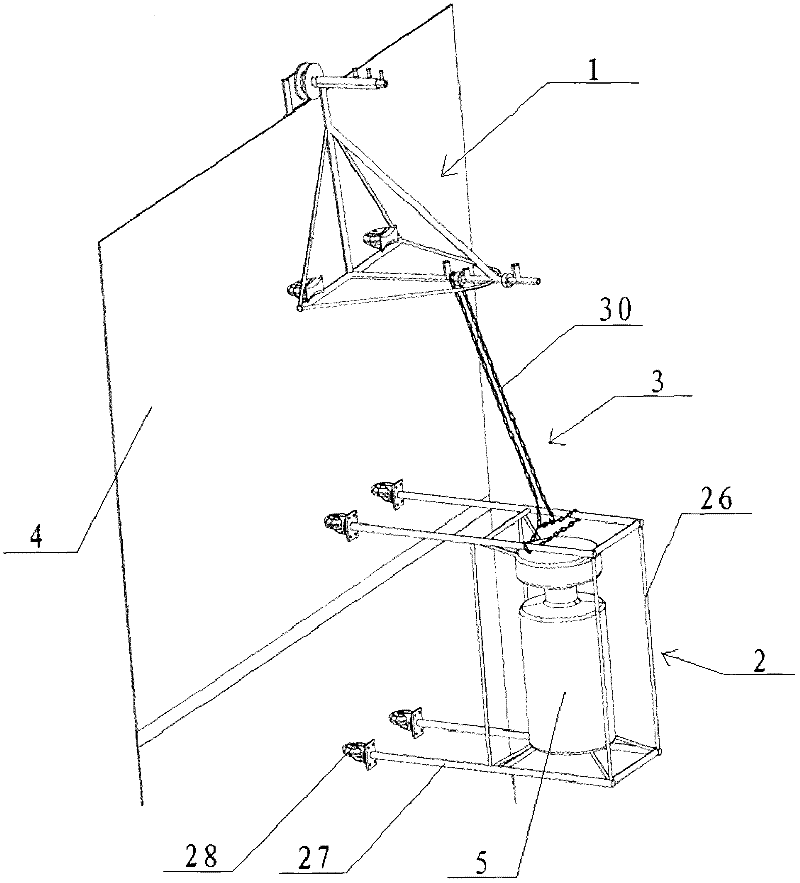

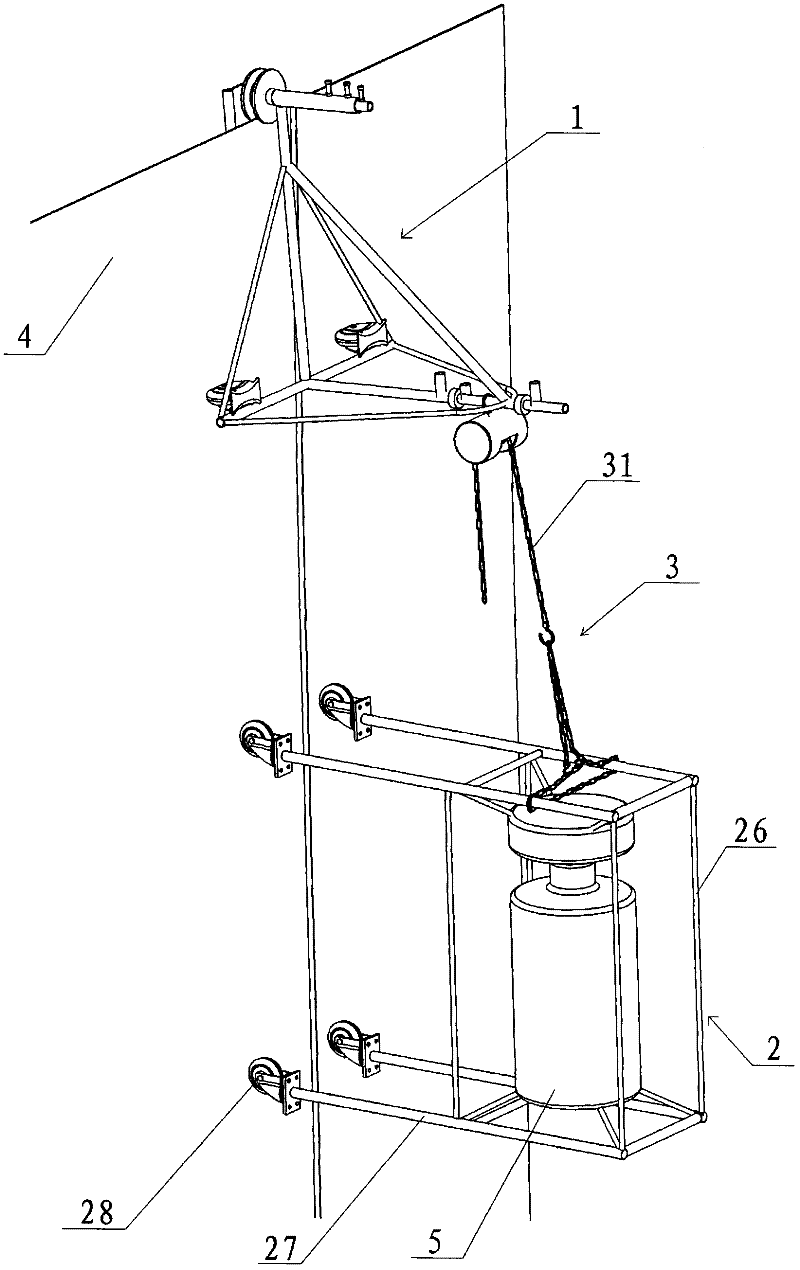

[0018] Such as figure 1 and figure 2 As shown, the walking device of the present invention includes a sliding part 1, a carrying part 2, a connecting part 3 connecting the sliding part 1 and the carrying part 2, and a traction part (not shown) for pulling the sliding part 1. The slide part 1 is clamped on both sides of the container wall 4 and can slide along these sides. The carrying part 2 is used to carry the fixed weld seam radiographic inspection machine 5 and can slide along one side of the container wall 4 .

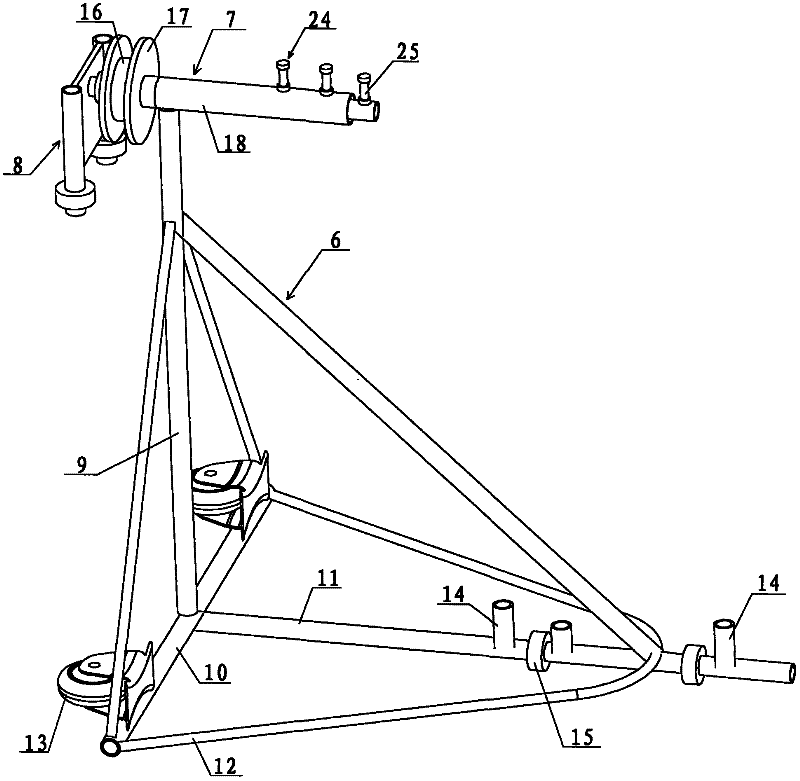

[0019] Such as image 3 As shown, the sliding part 1 includes a sliding suspension frame 6 , a traveling wheel structure 7 and a sliding clamping part 8 . The sliding suspension frame 6 includes a support rod 9 supporting the traveling wheel structure 7 , a pulley assembly rod 10 perpendicular to the support rod 9 , and a suspension rod 11 perpendicular to the support rod 9 and the pulley assembly rod 10 . The supporting rod 9, the pulley assembly rod 10 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com