Detection method of abnormal discharge of negative ion generator

A negative ion generator and abnormal discharge technology, applied in the direction of testing the dielectric strength, etc., can solve the problems of negative ion generator failure, inconvenient troubleshooting, negative ion generator can not work normally, etc., to achieve the effect of energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

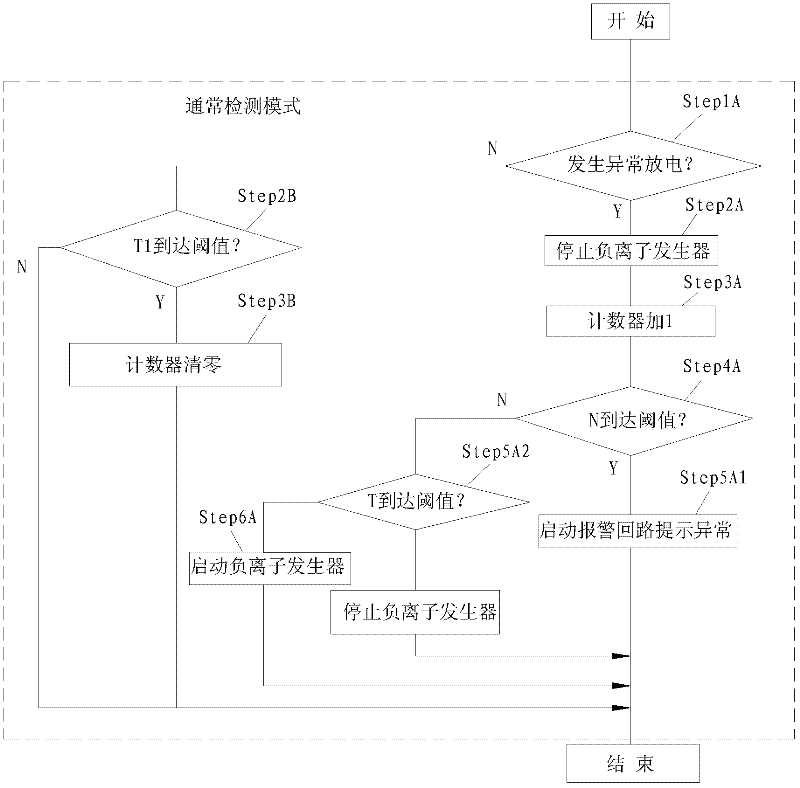

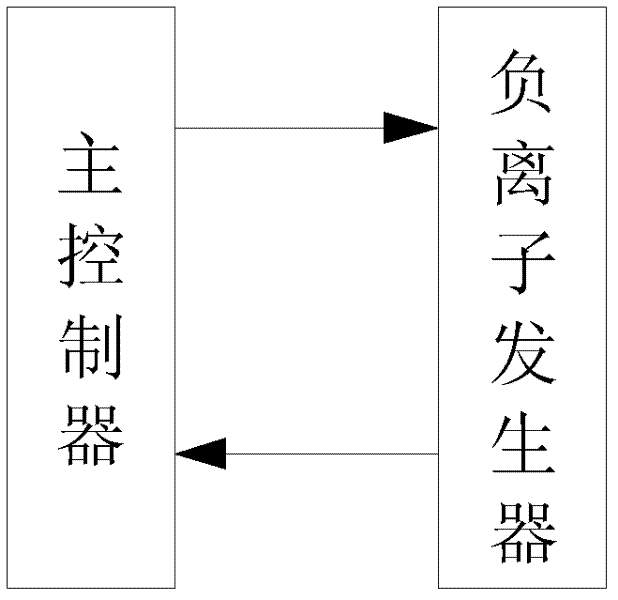

[0030] This embodiment discloses a detection method in the normal detection mode, and its corresponding circuit principle structure block diagram is as follows figure 2 As shown, the specific cycle execution steps of this mode are as follows figure 1 Shown:

[0031] Step1A: The main controller constantly monitors the abnormal discharge of the negative ion generator; specifically, it can be interrupted by abnormality or scanning from time to time; the abnormal interruption is: once the negative ion generator is abnormal, it actively transmits an interrupt request to the main controller to notify the main controller to perform follow-up actions; the scanning at all times is: the main controller continuously reads the working conditions of the negative ion generator; if the negative ion generator has an abnormal discharge, execute Step2A and subsequent steps, such as negative ion generation If there is no abnormal discharge of the counter, execute Step2B and subsequent counter ...

Embodiment 2

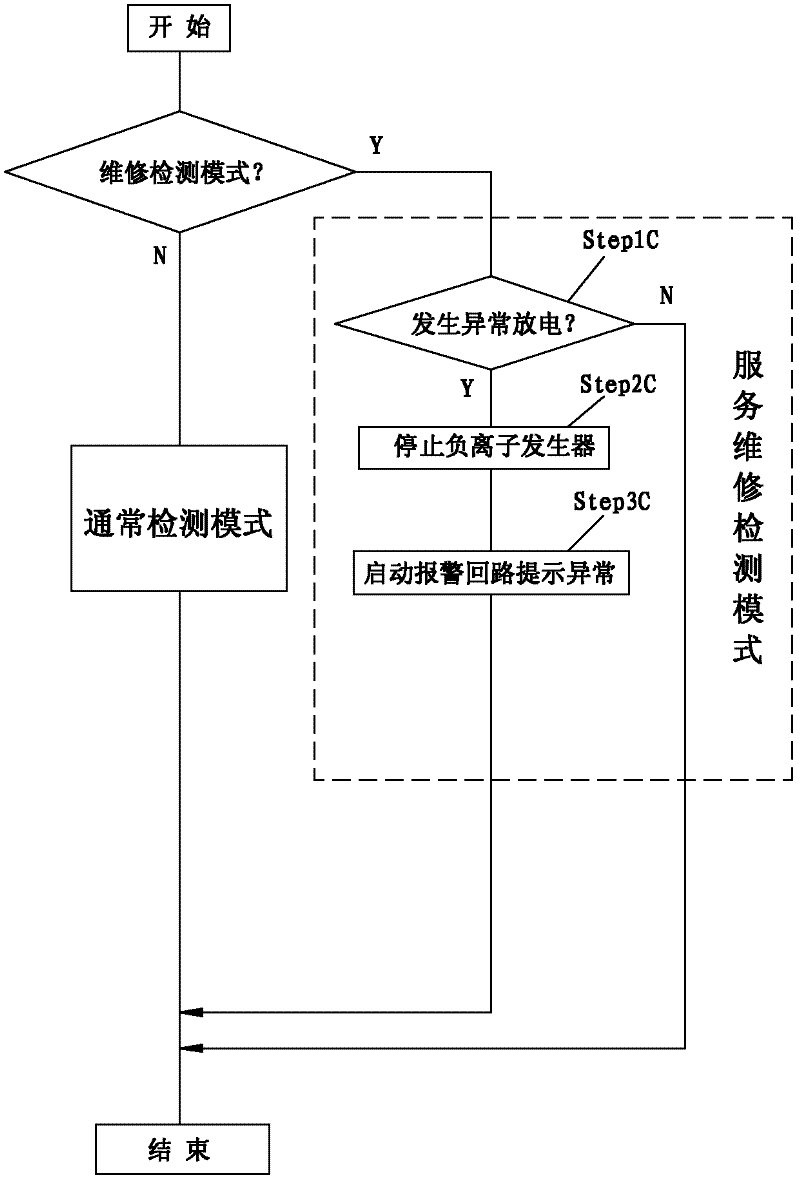

[0045]In this embodiment, on the basis of Embodiment 1, a service and maintenance detection mode is added. In actual operation, you can switch between the two through an infrared remote control, and set a receiver for receiving infrared codes in the main controller. Once the receiver receives the code of the maintenance detection mode, the main controller will enter the service maintenance detection mode , further rapid detection and troubleshooting, the specific steps of this mode are as follows image 3 Shown:

[0046] Step1C: The main controller continuously detects whether there is an abnormal discharge of the negative ion generator (specifically, it can be abnormally interrupted or scanned from time to time). If it detects that the negative ion generator has abnormal discharge, the steps after Step2C will be executed sequentially;

[0047] Step2C: The main controller sends a shutdown signal to the negative ion generator to turn off the power of the negative ion generator...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com