RFID (radio frequency identification) technology based non-metallic ion grounding body management method and system

A management method and non-metallic technology, applied in grounding resistance measurement, inductive recording medium, data processing applications, etc., can solve the problems of high price, low resistance of non-metallic body, corrosion and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

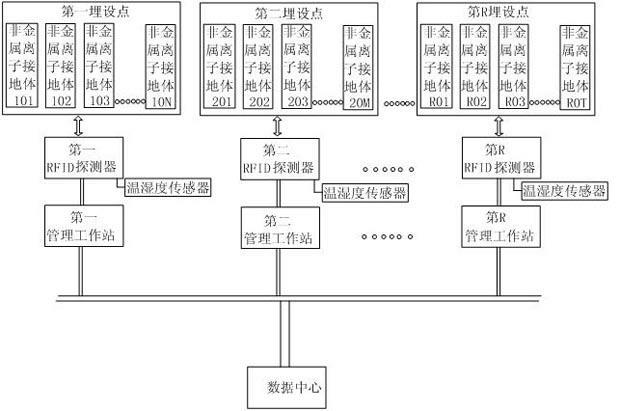

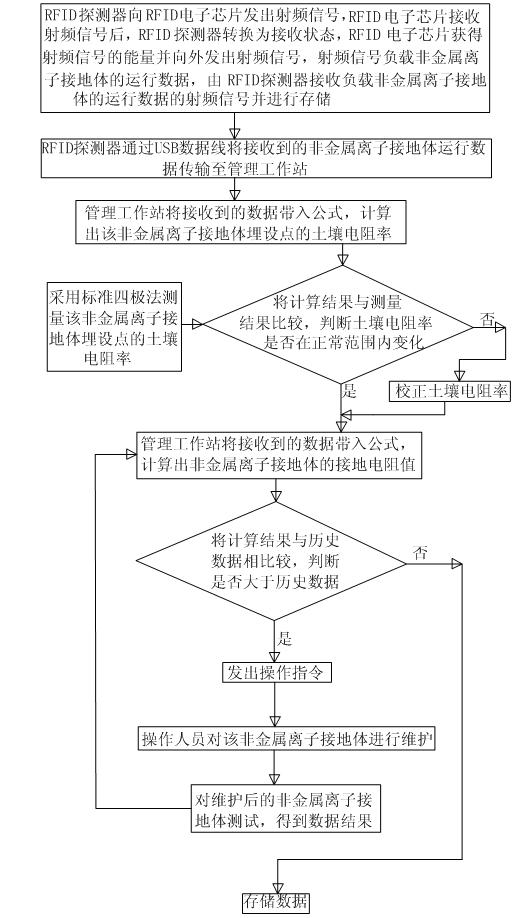

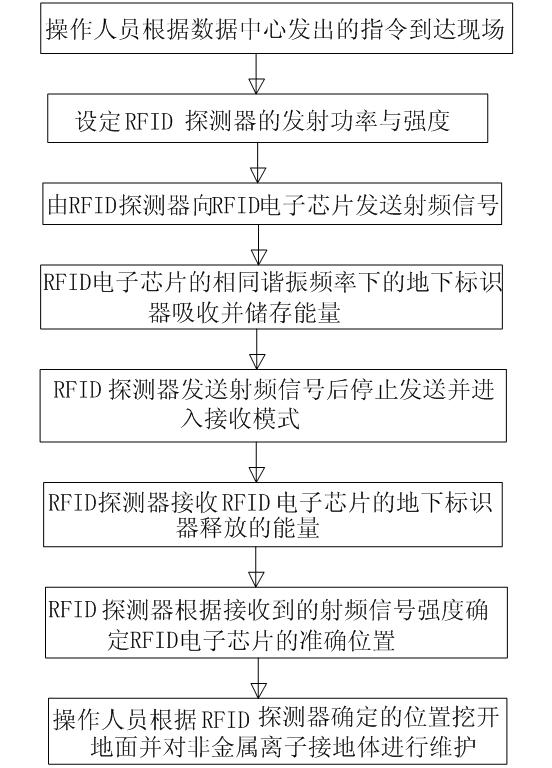

[0063] Such as Figures 1 to 4 As shown, the present invention is based on the non-metallic ion grounding body management system of RFID technology,

[0064] In a region, there are R non-metal ion grounding body buried points, wherein, the first buried point has N non-metal ion grounding bodies, and the second buried point has M non-metal ion grounding bodies, so that By analogy, the Rth buried point has T non-metallic ion grounding bodies, wherein R, N, M, and T are all natural numbers, and RFID electronic chips are installed in each non-metallic ion grounding body, and the RFID electronic chips are passive Chips include antennas and integrated circuit chips. The antenna is a copper film coil plated on a plastic substrate, and a very small integrated circuit chip is embedded on the plastic substrate. The integrated circuit chip consists of a high-speed radio frequency interface, a control unit, EEPROM consists of three modules; each embedded point corresponds to an RFID dete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com