Device for converting substrate integrated waveguide to coaxial waveguide

A substrate-integrated waveguide and coaxial waveguide technology, applied in the direction of connection devices, waveguide devices, electrical components, etc., can solve the problems of increased insertion loss, waste of resources, miniaturization resistance, etc., to achieve small device size, easy assembly and disassembly , the effect of low loss conversion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

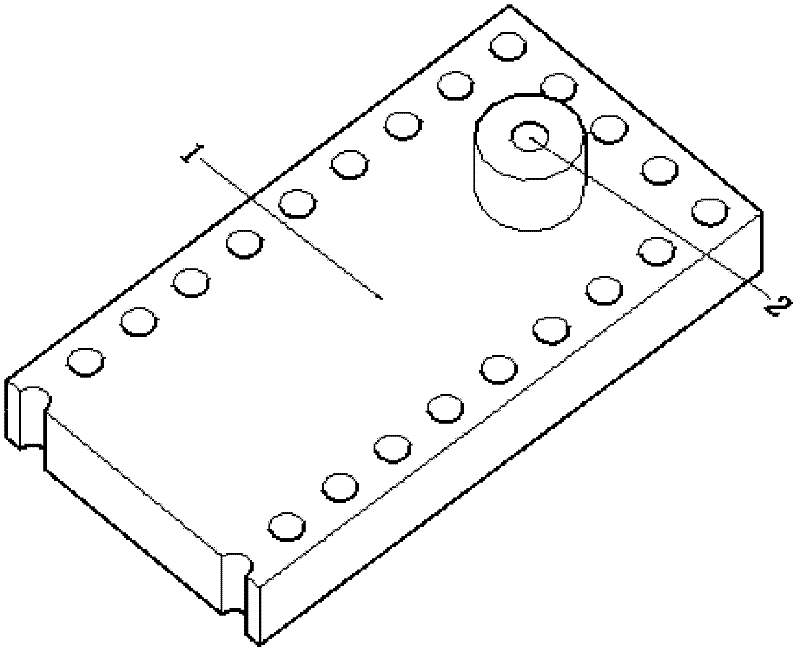

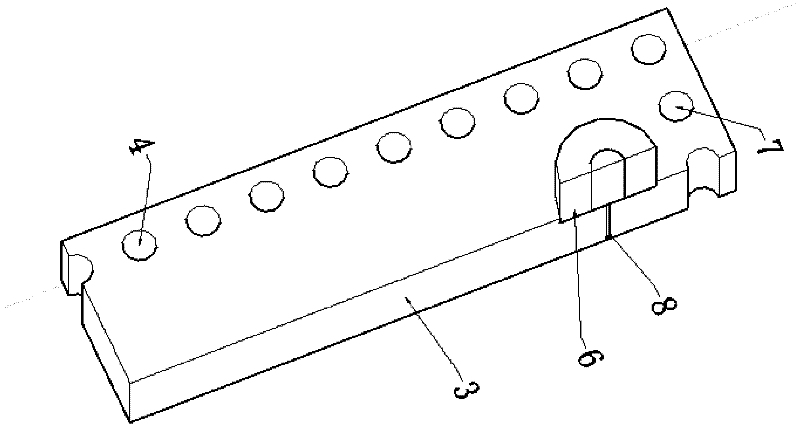

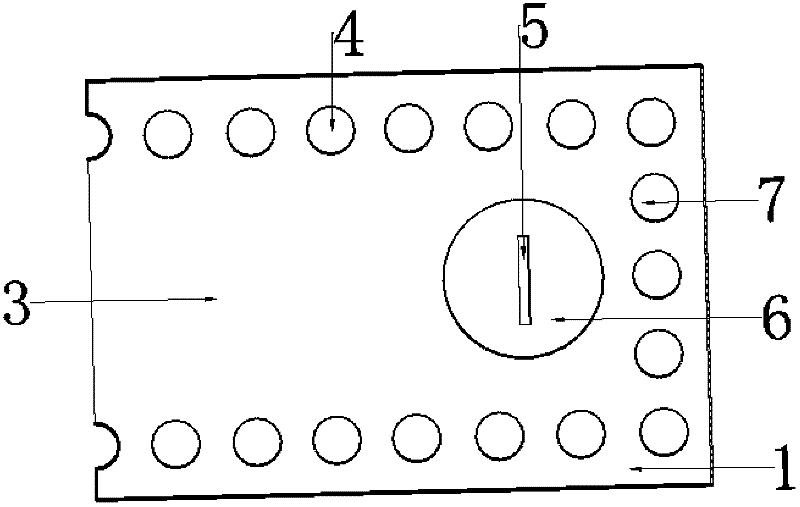

[0019] combine figure 1 and image 3 , taking the X-band as an example, the thickness of the dielectric substrate 3 of the substrate-integrated waveguide joint 1 is 3mm, the diameter of the two rows of metallized through-holes 4 is 0.4mm, and the distance between adjacent holes of each row of metallized through-holes 4 is 1.9mm , the distance between two rows of metallized through holes 4 is 22mm, the wide side of the dielectric substrate 3 is 24mm, the size of the rectangular groove 5 is 1.6mm×0.1mm, and the depth is 2.9mm; the diameter of the metal short circuit hole 7 is 0.4mm , the hole spacing is 2mm, and the diameter of the circular window 6 is 7mm. The cross-sectional size of the sheet probe 8 at the front end of the coaxial inner conductor of the coaxial waveguide joint 2 is 1.6 mm×0.1 mm, and the length of the probe is 2.9 mm. The coaxial cable of the coaxial waveguide connector 2 is a 50Ω standard coaxial cable, the diameter of the inner conductor is 3.04mm, and t...

specific Embodiment 2

[0021] combine figure 2 and image 3 , taking the X-band as an example, the thickness of the dielectric substrate 3 of the substrate-integrated waveguide connector 1 is 3mm, the diameter of the two rows of metallized through-holes 4 is 0.5mm, and the distance between adjacent holes in each row of metallized through-holes 4 is 1.9mm , the distance between two rows of metallized through holes 4 is 22mm, the wide side of the dielectric substrate 3 is 23.56mm, the size of the rectangular groove 5 is 1.6mm×0.1mm, and the depth is 2.9mm; the diameter of the metal short circuit hole 7 is 0.5 mm, the hole spacing is 2mm, and the diameter of the circular window 6 is 7mm. The cross-sectional size of the sheet probe 8 at the front end of the coaxial inner conductor of the coaxial waveguide joint 2 is 1.6 mm×0.1 mm, and the length of the probe is 2.9 mm. The coaxial cable of the coaxial waveguide connector 2 is a 50Ω standard coaxial cable, the diameter of the inner conductor is 3.04mm...

specific Embodiment 3

[0023] combine figure 1 and image 3 , taking the X-band as an example, the thickness of the dielectric substrate 3 of the substrate-integrated waveguide connector 1 is 3mm, the diameter of the two rows of metallized through-holes 4 is 0.6mm, and the distance between adjacent holes of each row of metallized through-holes 4 is 1.5mm , the distance between two rows of metallized through holes 4 is 22mm, the wide side of the dielectric substrate 3 is 23.56mm, the size of the rectangular groove 5 is 1.5mm×0.1mm, and the depth is 2.9mm, and the diameter of the metal short circuit hole 7 is 0.6 mm, the hole spacing is 1mm, and the diameter of the circular window 6 is 7mm. The slice probe 8 at the front end of the coaxial inner conductor of the coaxial waveguide connector 2 has a cross-sectional dimension of 1.5 mm×0.1 mm, and a probe length of 2.9 mm. The coaxial cable of the coaxial waveguide connector 2 is a 50Ω standard coaxial cable, the diameter of the inner conductor is 3.0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Insertion loss | aaaaa | aaaaa |

| Insertion loss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com