Shielding insulating body, shielding connector and manufacturing method for shielding connector

A technology of an insulating body and a manufacturing method, which is applied in the field of a shielded insulating body, can solve problems such as cumbersome processing steps, increase production costs, and complex processing techniques, and achieve the effects of reducing production costs, preventing short circuits, and simplifying processing techniques

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

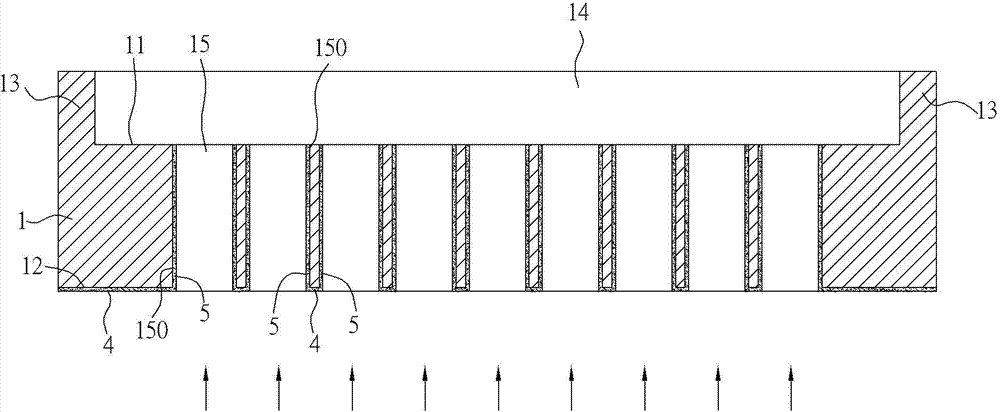

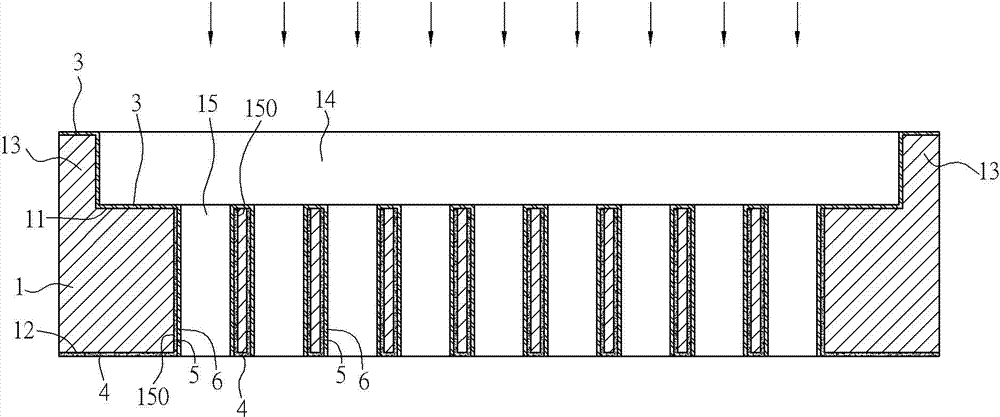

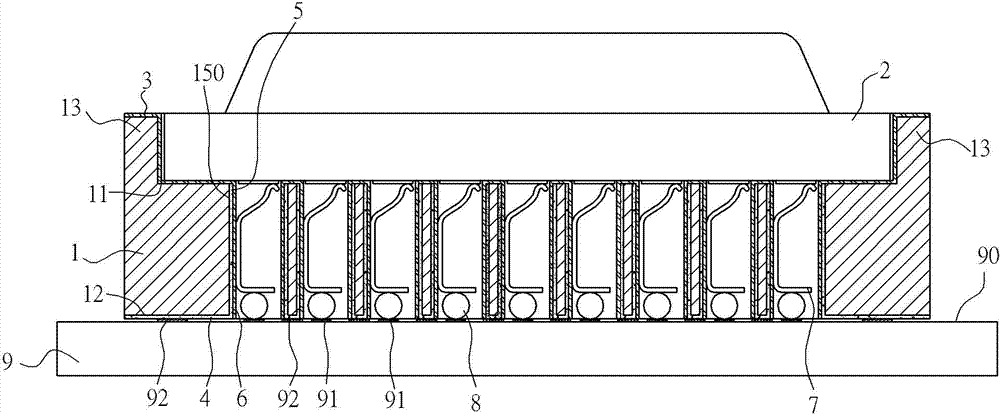

[0035] like figure 1 and figure 2 As shown in , the shielded connector of the present invention includes an insulating body 1 , which is substantially in the shape of a cuboid, and has a top surface 11 and a bottom surface 12 opposite to the top surface 11 . The insulating body 1 is integrally provided with four retaining walls 13 protruding upward from the top surface 11 around the four sides, and the four retaining walls 13 and the top surface 11 form a groove 14 for carrying a chip module 2. The retaining wall 13 can guide the chip module 2 into the groove 14 and limit it. The top and side surfaces of the four retaining walls 13 and the top surface 11 of the insulating body 1 are covered with a first insulating layer 3, the first insulating layer 3 is exposed to the air, and the bottom surface 12 is covered with There is a first metal layer 4, which is exposed to air.

[0036] The insulating body 1 is provided with a plurality of through holes 15 penetrating through th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com