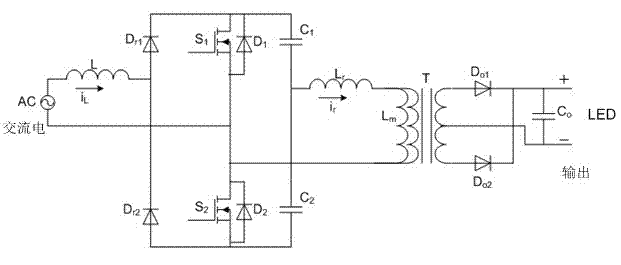

Single-stage AC-DC (alternating current-direct current) high-power LED (light-emitting diode) lighting drive circuit

An LED driving, high-power technology, applied in lighting devices, lamp circuit layout, output power conversion devices, etc., can solve the problems of many LED driving circuit devices, short life, high cost, avoid adverse effects, and small capacitance. , the effect of low power factor harmonics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

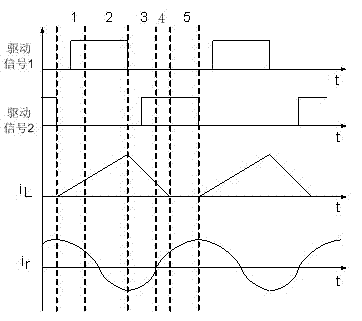

Method used

Image

Examples

Embodiment approach

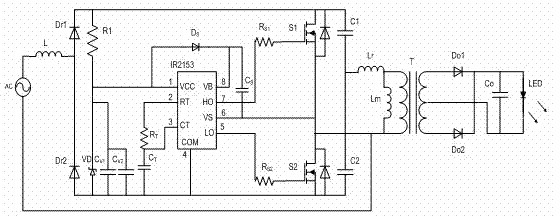

[0022] Such as image 3 As shown, it is a specific implementation of simple open-loop control of the present invention, and the specific implementation is as follows: image 3 The main circuit and figure 1 The main circuit is exactly the same, and its basic composition and working process are also the same as figure 1 The circuits are the same, and the main difference is that an implementation circuit of the control circuit of the LED driver is specifically shown. Therefore, the following mainly introduces the composition, specific implementation and working process of the control circuit.

[0023] The control circuit uses the IR2153 chip as the core, which generates a high-frequency square wave control pulse with a duty cycle of 50% and a phase difference of 180°, and sends it to the power switch tube S 1 , S 2 gate pole. The specific composition of the control circuit includes the resistance R 1 , the Zener diode VD, the capacitor C v1 and C v2 , the integrated circu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com