Deep hole processing method and device thereof

A processing method and technology of processing device, applied in metal processing equipment, manufacturing tools, boring/drilling and other directions, can solve the problems of broken drill bit, workpiece damage, insufficient adjustment angle of adjustable tilt platform, etc. The effect of insufficient drill pipe length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

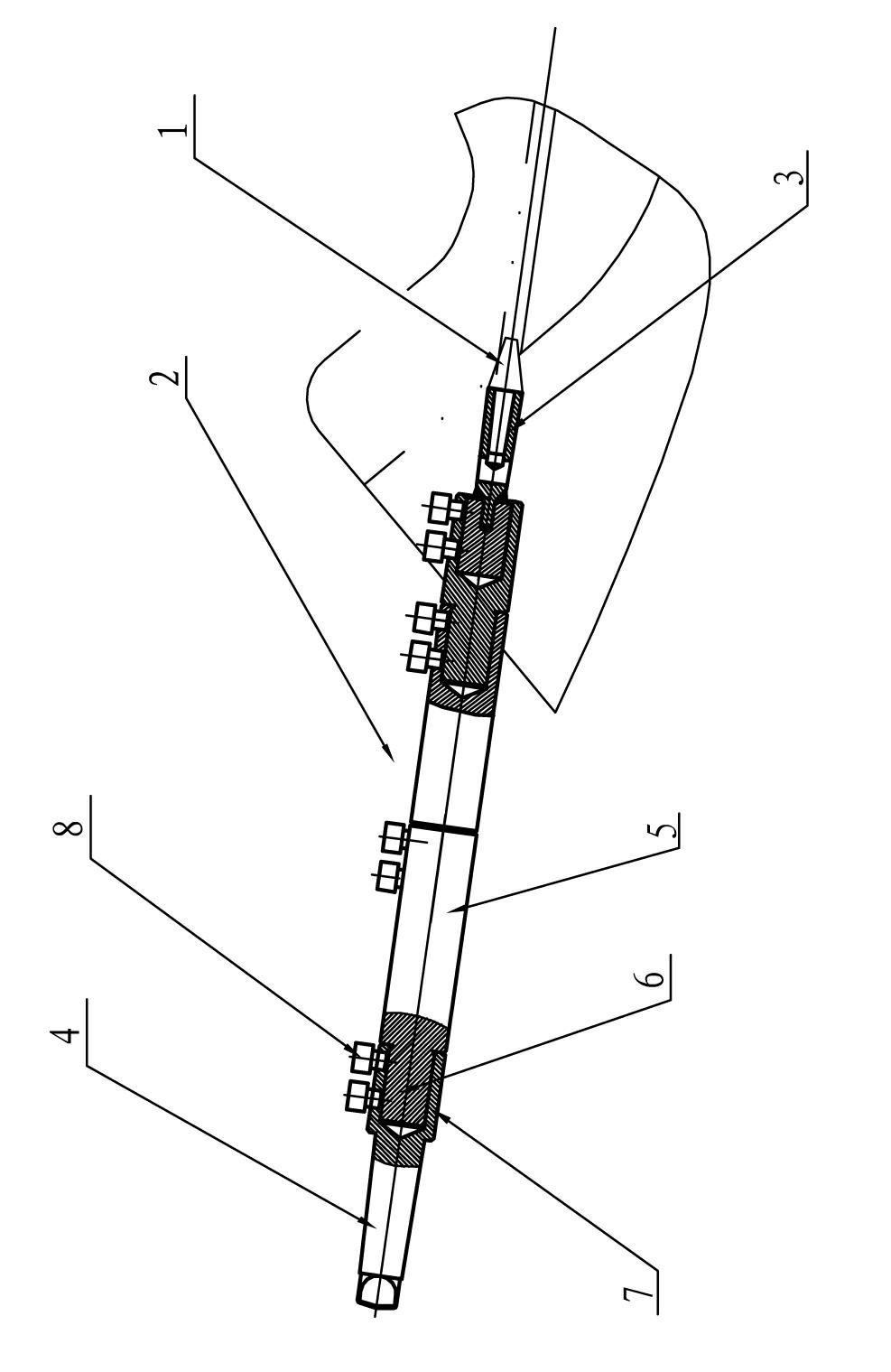

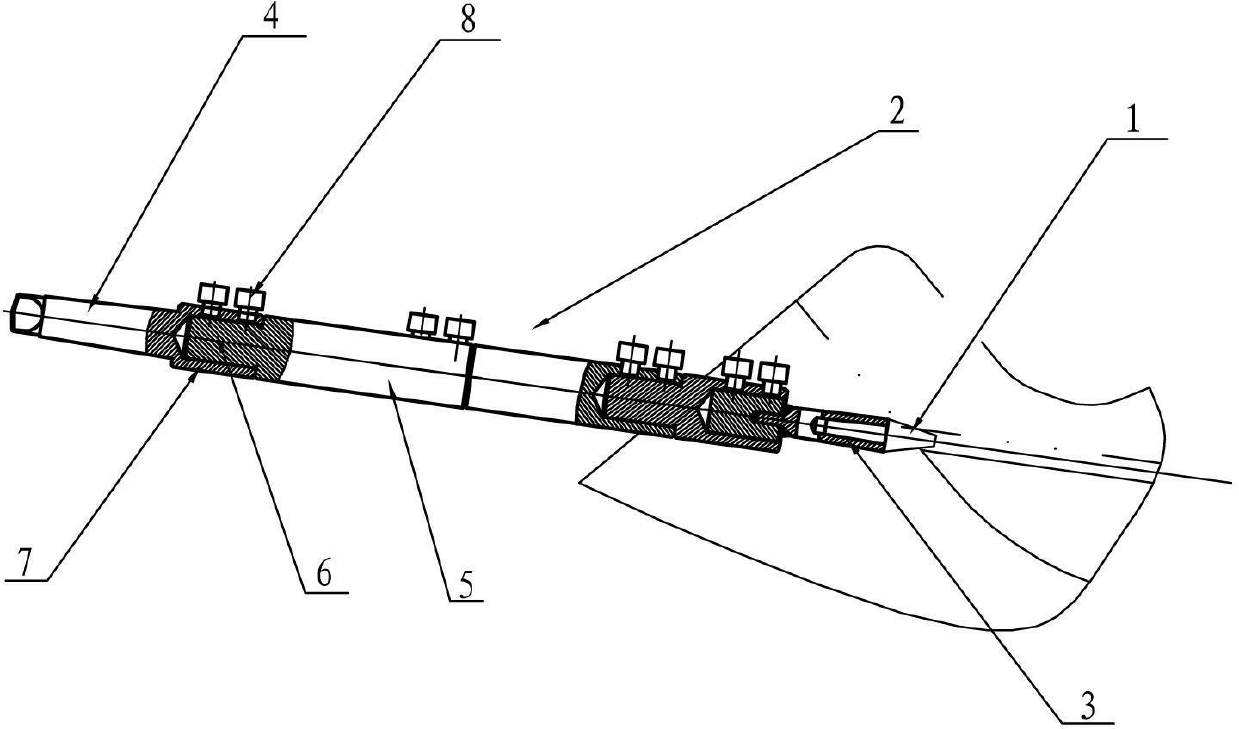

[0019] refer to figure 1 , the present invention is a kind of deep hole processing method, comprises the following steps:

[0020] 1) Carry out pre-drilling at the required drilling position;

[0021] 2), exit the drill bit 1 used for drilling, lengthen the drill rod 2 of the drill bit 1, and withdraw the drill bit 1 after the processed deep hole reaches the depth that the lengthened drill rod 2 can process;

[0022] 3) Repeat step 2) to complete the required depth of drilling.

[0023] This method of deep hole drilling realizes the processing of deep holes by gradually increasing the drill rod 2 of the drill bit 1 used for drilling, effectively solving the problem of insufficient length of the drill rod 2 in the process of deep hole drilling, and at the same time performing the drilling step by step The hole helps to reduce the damage to the workpiece caused by problems such as poor chip removal and drill bit deviation during the drilling process, and helps to improve the q...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap