Positioning processing method of cylinder member with large slenderness ratio

A processing method and technology of slenderness ratio, applied in metal processing equipment, manufacturing tools, auxiliary devices, etc., can solve the problems of difficult control of deformation of slender parts and insufficient processing accuracy, so as to save the work of alignment and adjustment Quantity, low manufacturing cost, and improved work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

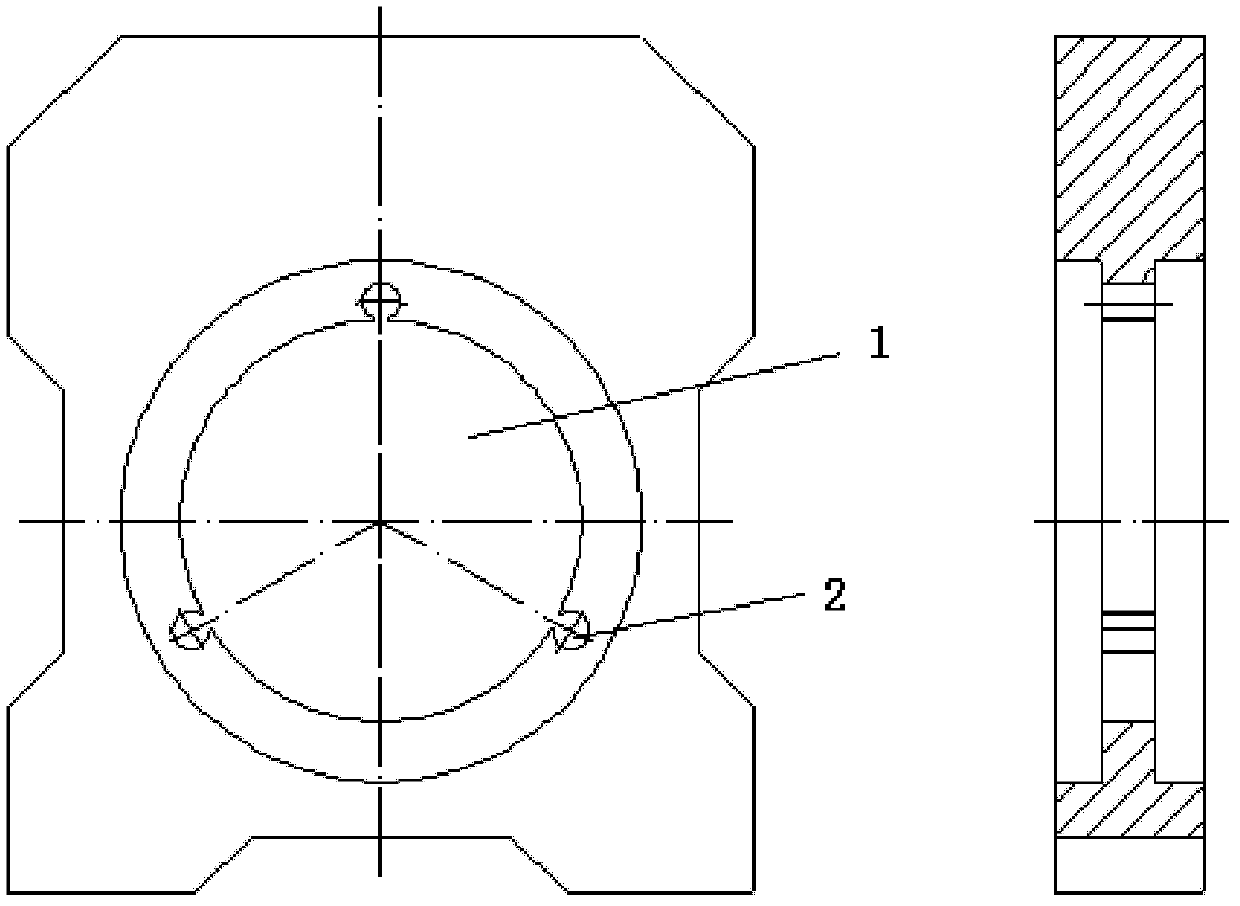

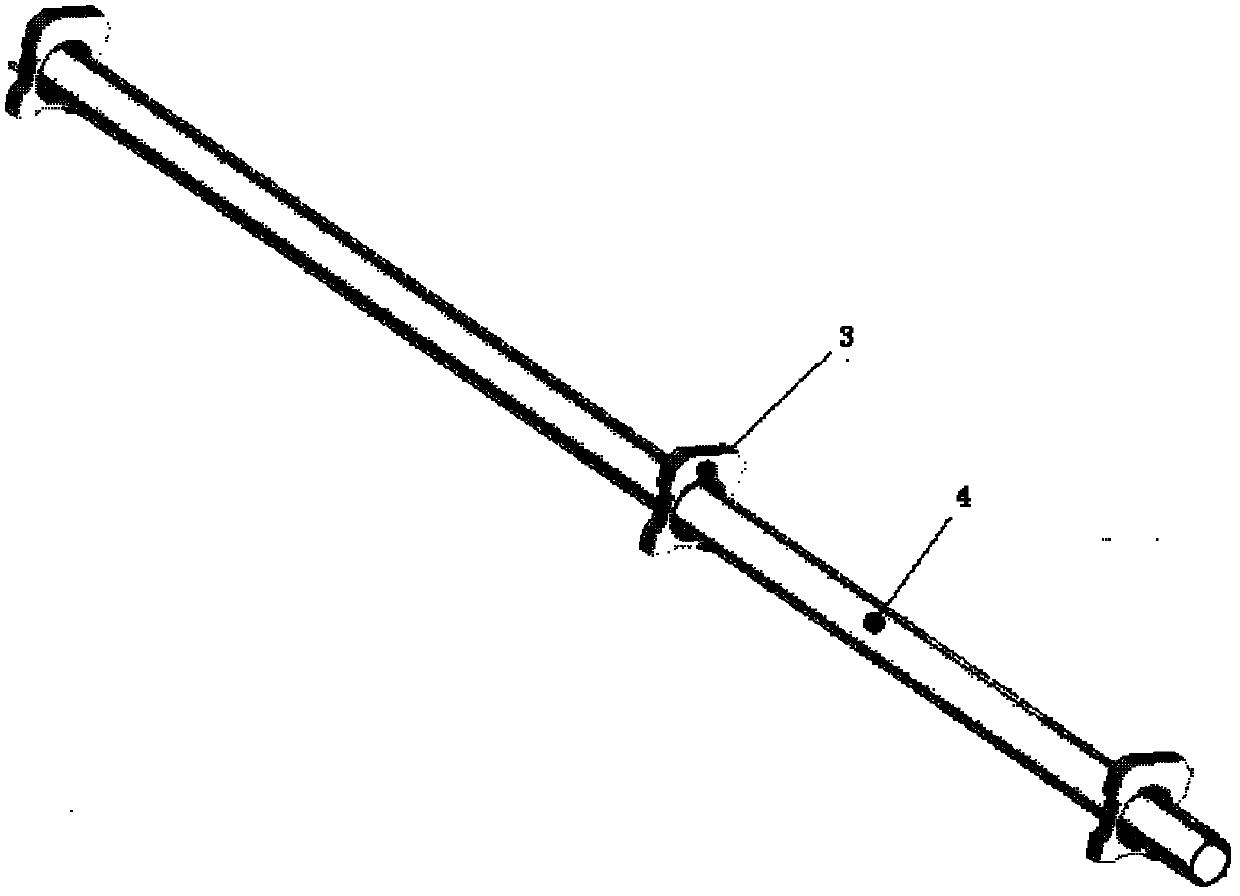

[0040] The cylinder has a length of 4500 mm, an outer diameter of 108 mm, and a wall thickness of 4 mm. The diameter of the support rod is 10mm and the length is 4600mm. The design requirements of the components are: three support rods are fixed on the outer surface of the cylinder by spot welding.

[0041] First, control the dimensional accuracy of the outer circle of the cylinder and the support rod. After the support rod is fitted on the outer surface of the cylinder (that is, tangent), the first two solder joints are fixed. After the first fixation, the cylinder and the support rod are fixed. The mutual position of the axes is established. The second fixed point fits the two outer circles according to the method of the first fixed point, and the vertical direction (Y direction) ± in the radial direction (the line connecting the center of the cylinder and the support rod through the tangent point) of the first fixed point Implement the second two solder joints within 0.5 ...

Embodiment 2

[0043] After the first support rod is fixed on the outer surface of the cylinder, the latter two processes—fixed welding of the second support rod and the third support rod—begin to be implemented. Before each process thereafter, the 120° space position between the support rod of this process and the first support rod must be found. In addition, it is also necessary to control the axial corresponding positions of every two welding spots at the 48 fixing positions and the two welding spots at the fixing position of the first support rod, so as to ensure the axial position requirements of the welding spots of the 48 groups of components. Therefore, the workload of alignment and adjustment is very large and difficult, and the reliability of the process is also low, so it is difficult to guarantee product quality.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com