Compact high-rigidity layout structure of dry cutting gear hobber

A technology of dry cutting and layout structure, which is applied in the field of gear hobbing machines, can solve the problems of difficult design of fast chip removal structure, large space occupied by the whole machine, unsuitable layout structure, etc., to achieve compact structure, small space occupation of cutting area, and occupation of small space effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

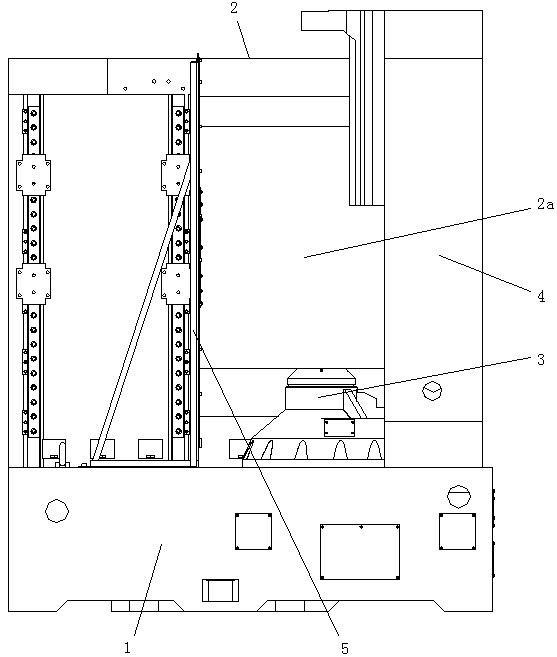

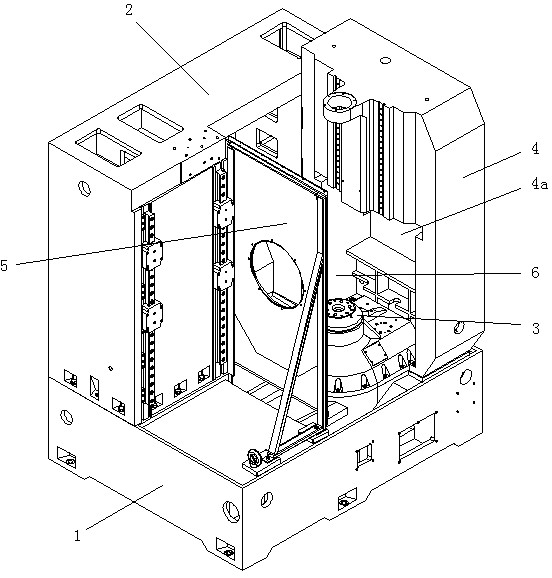

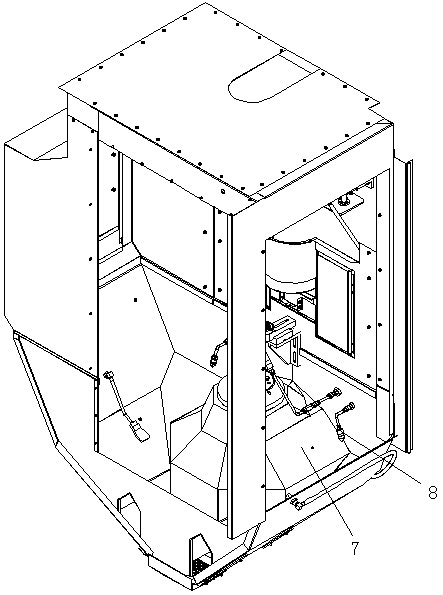

[0018] figure 1 It is the front view of the layout structure of the compact high rigidity dry cutting gear hobbing machine of the present invention; figure 2 A three-dimensional view of the layout structure of this compact high-rigidity dry cutting gear hobbing machine; image 3 It is a schematic diagram of the three-dimensional structure of the cutting shield; Figure 4 A three-dimensional view of the layout structure of this compact high-rigidity dry cutting gear hobbing machine with a chip guard.

[0019] As shown in the figure, the layout structure of the compact high-rigidity dry cutting gear hobbing machine in this embodiment includes a bed 1, a large column 2, a workbench 3 and a rear column 4, and the large column 2 is arranged on the longitudinal side of the bed 1 Above, the rear column 4 is arranged on the lateral side of the bed 1, the ends of the large column 2 and the rear column 4 are connected to form an L-shaped structure, and the middle part of the bed is a...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap