Drilling device of hexagon bolt

A hexagonal bolt and drilling device technology, which is applied in the field of machining, can solve the problem that hexagonal bolt drilling cannot be accurately positioned, and achieve the effects of simple structure, convenient operation and accurate positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

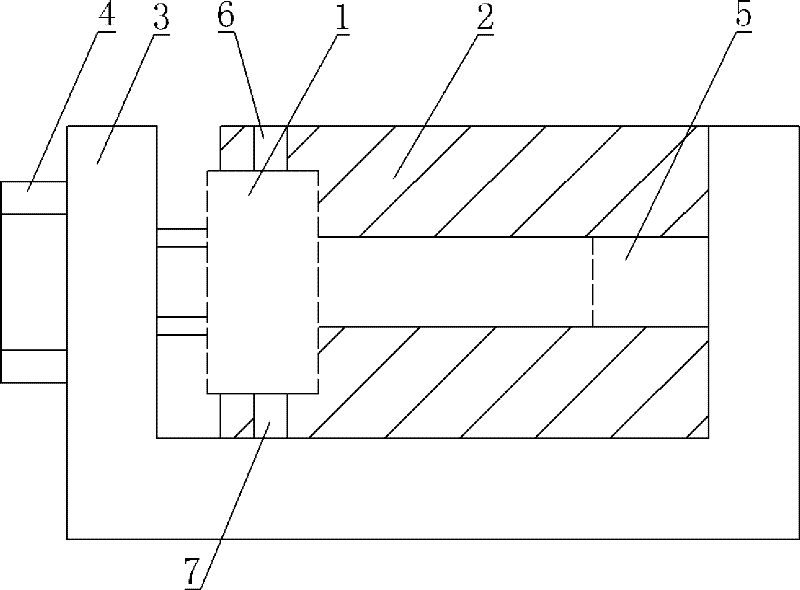

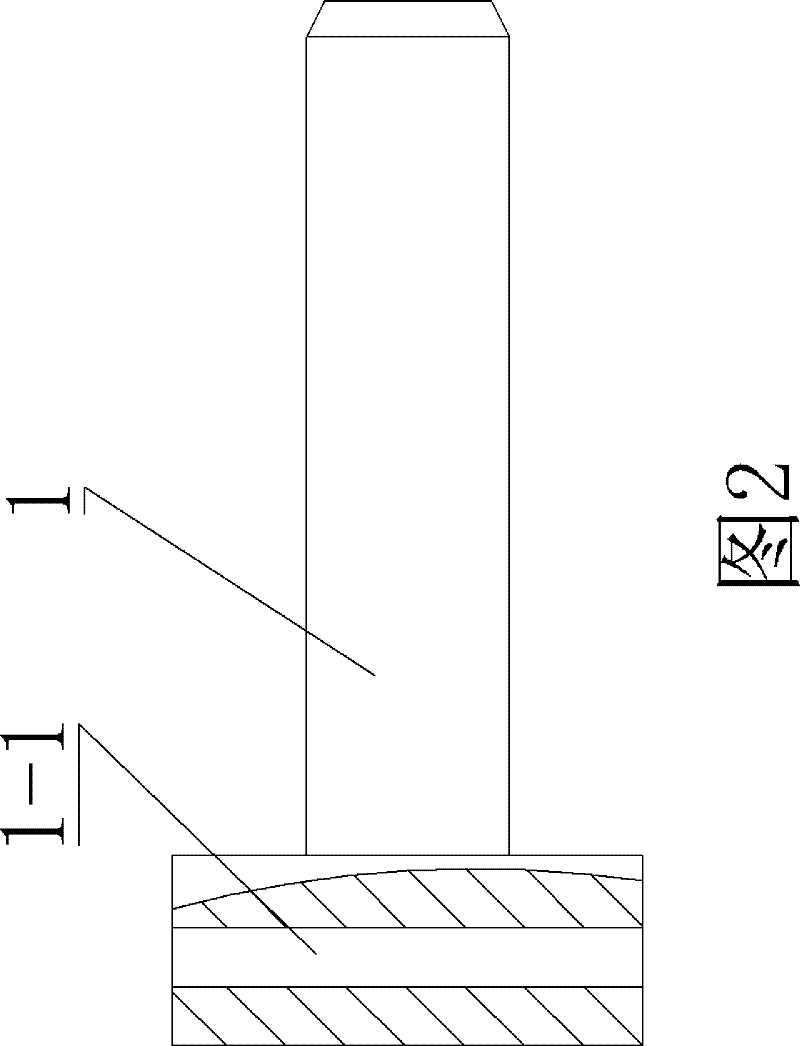

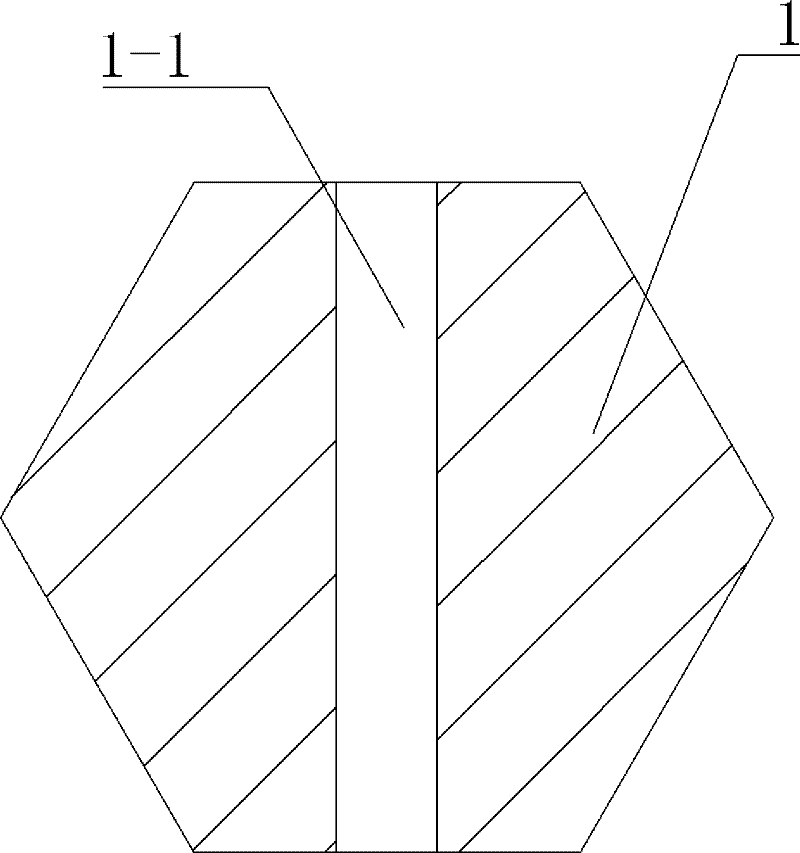

[0015] The embodiment of the drilling device of the hexagon bolt of the present invention: as Figure 1 to Figure 5 As shown, the drilling device is mainly composed of a clamping mechanism and a clamping block 2, wherein the clamping mechanism is mainly composed of a U-shaped support seat 3 and a locking bolt 4 pierced on one side wall of the support seat 3, and The clamping block 2 is located in the opening of the support base 3. The clamping block 3 is provided with mounting holes 5 which are perpendicular to the side walls on both sides of the support base 3 for the hexagonal bolts 1 to be inserted into. The clamping block 2 is located close to the locking bolts. One end of 4 is provided with an in-line mounting groove 5-1 that communicates with the mounting hole 5 and is used for embedding the head of the hexagonal bolt 1. The groove walls on both sides are attached to each other, and the limit surface can be squeezed and fit with the end face of the head of the hexagonal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com