Small grinding wheel creep feed grinding processing method capable of adjusting cutting angle for engineering ceramic

A technology of slow-feed grinding and cutting angle, which is applied in the processing field of small grinding wheel with adjustable cutting angle and slow-feed grinding engineering ceramics, which can solve the problems of low processing efficiency, insufficient system rigidity and high cost, and achieve guaranteed processing Effects on efficiency and processing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

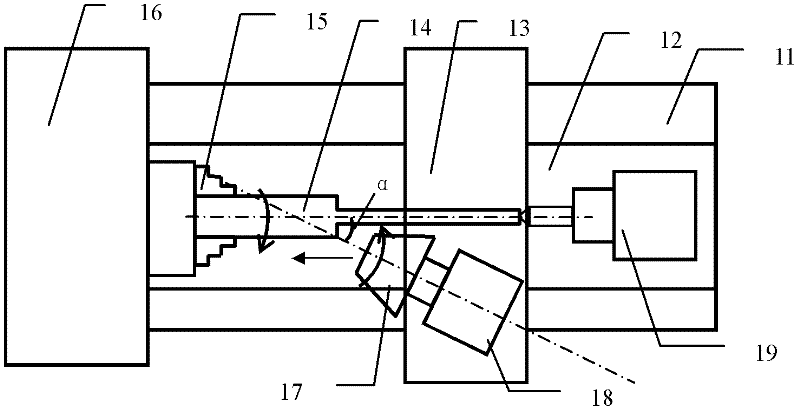

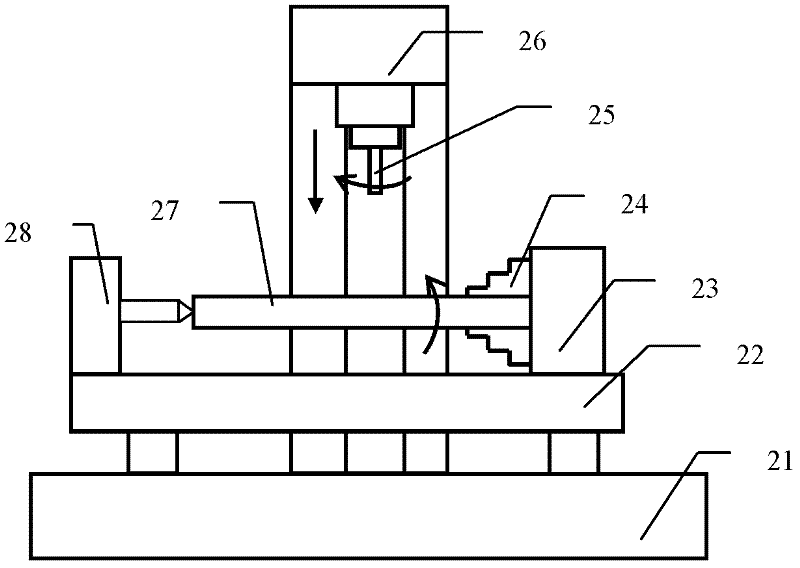

[0019] The small grinding wheel slow-feed grinding method with adjustable cutting angle proposed by the present invention is further described as follows in conjunction with accompanying drawings and examples:

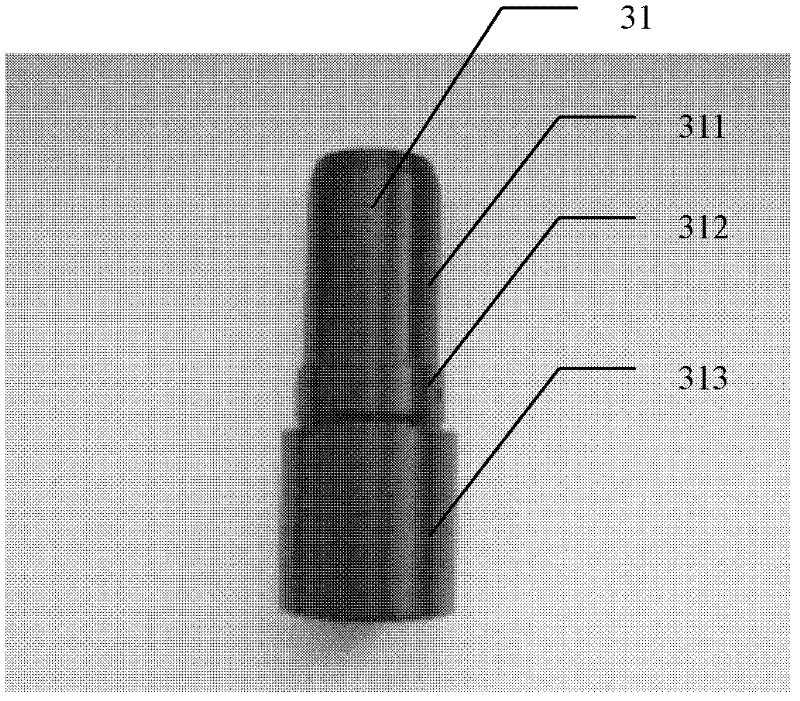

[0020] The small grinding wheel with adjustable cutting angle and slow-feed grinding engineering ceramics processing method of the present invention is used for processing the outer cylindrical surface of engineering ceramics hard and brittle materials. The small grinding wheel is a conical diamond grinding wheel, and it is characterized in that: the small grinding wheel The outer diameter of the grinding wheel table is φ10-100mm, and the angle between the generatrix of the grinding wheel table and the axis of the grinding wheel is θ, and the range of the angle θ is between 0° and 45°; during processing, the axis of the diamond grinding wheel and the axis of the grinding wheel are The axis of the workpiece is in the same horizontal plane or vertical plane, and the machi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com