Automatic maintaining room for commercial housing components

A technology for curing rooms and houses, which is applied in the field of automatic curing rooms for productized residential parts, can solve problems such as large volume and weight, and achieve the effects of reasonable structure, convenient operation and improved maintenance efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

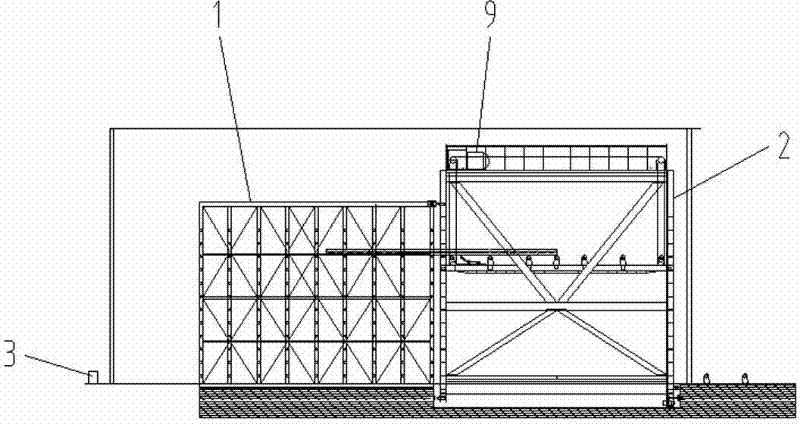

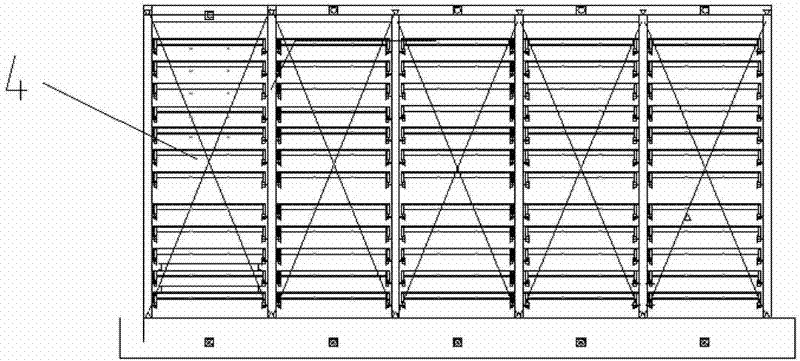

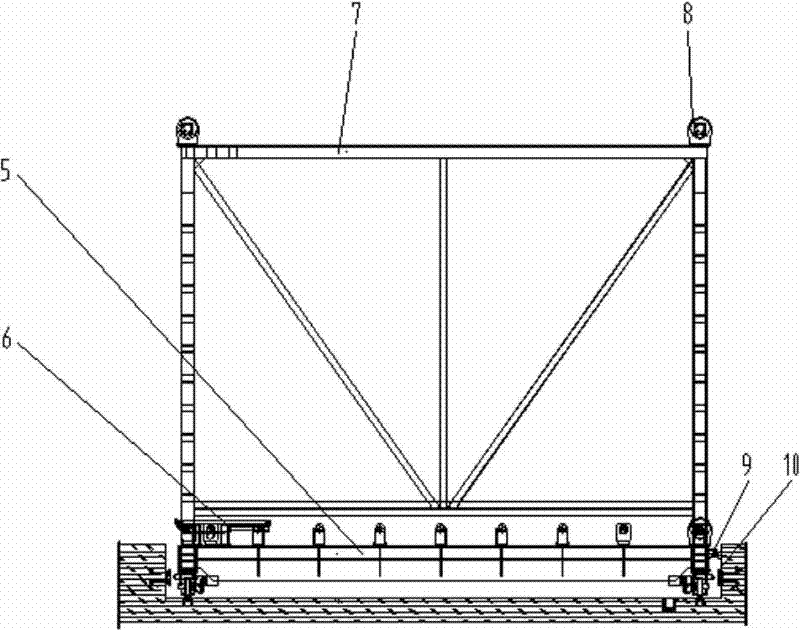

[0025] see figure 1 , figure 2 , image 3 , Figure 4 with Figure 5 , an automated maintenance room for commercialized housing components , Including the curing room shelf 1, the mobile lift car 2 and the control system 3, the curing room shelf 1 is composed of three parts: the frame steel structure, the supporting wheel system and the infrared beam sensor 4, and the top of the curing room shelf 1 is installed on the first beam There are 5 sets of positioning ball sockets, sleeves, and frame steel structure. The main material of the frame is HW250×175×7×11. Welding, then use a level meter, infrared straight meter to calibrate, and then pouring again, the supporting wheel mounting holes on the shelf pillars are processed by a gantry milling machine to ensure the position of the holes, and all the axle mounting holes should be arranged from outside...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com