Grain impurity content detection method

A technology of impurity content and detection method, applied in the field of detection, can solve the problems of large amount of radiation, high cost, inability to restore interlayer information, etc., and achieve the effect of rapid calculation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A detection method of grain impurity content:

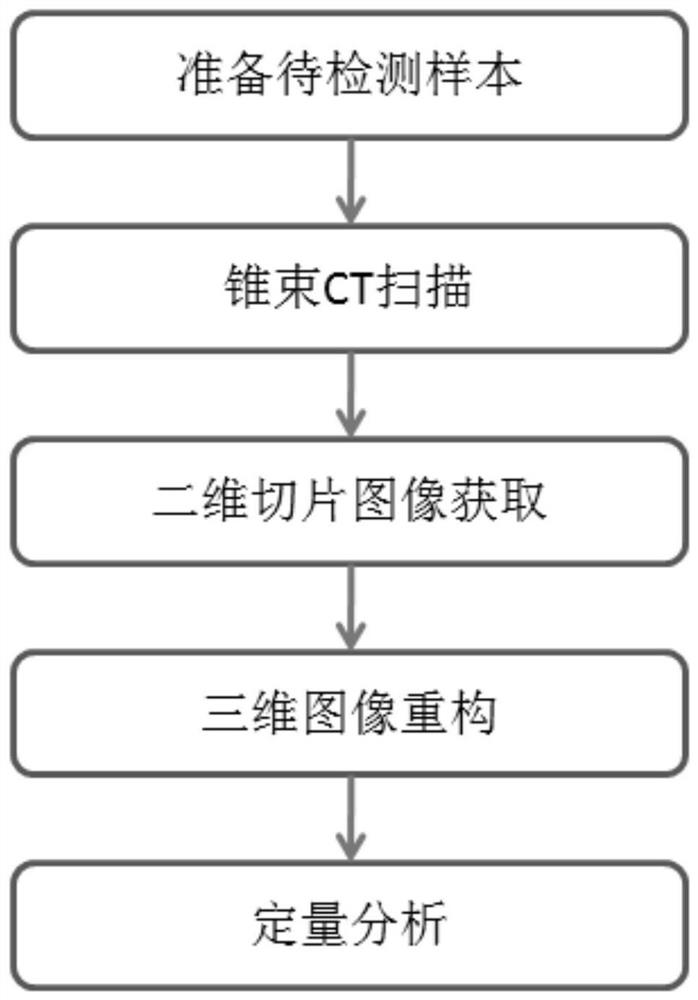

[0025] The experimental flow chart of embodiment 1 is as figure 1 shown.

[0026] Source of materials: The materials required for the experiment come from the Xinglong National Grain Reserve in Zhengzhou City, Henan Province.

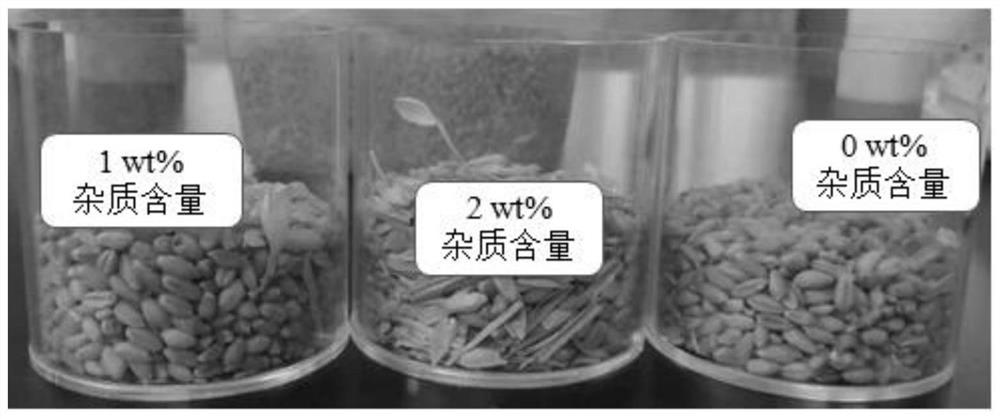

[0027] (1) The grain sample is composed of wheat and organic impurities, and the organic impurities are wheat husk and wheat straw. There are 3 test samples, all of which have a total weight of 50g, and the impurity contents of organic impurities are 2wt%, 1wt%, and 0wt%, respectively. Place the grain samples in transparent acrylic containers with a height of 6 cm, a bottom diameter of 6 cm, and a container wall thickness of 3 mm, such as figure 2 shown. During the X-ray rotary scanning process, the shape of the sample to be tested is required not to change. If a certain part of the sample is shifted during the detection process, the detection will fail. Therefore, when preparing the sample, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com