PTFE (Polytetrafluoroethylene) unsintered tape forming device

A technology of polytetrafluoroethylene and molding devices, which can be used in belts, other household appliances, household appliances, etc., can solve problems such as difficulties, and achieve the effect of being easy to be stretched and having uniform and stable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] This specific embodiment is only an explanation of the present invention, and it does not limit the present invention. Those skilled in the art can make modifications without creative contribution to the present embodiment as needed after reading this specification, but as long as the rights of the present invention are used All claims are protected by patent law.

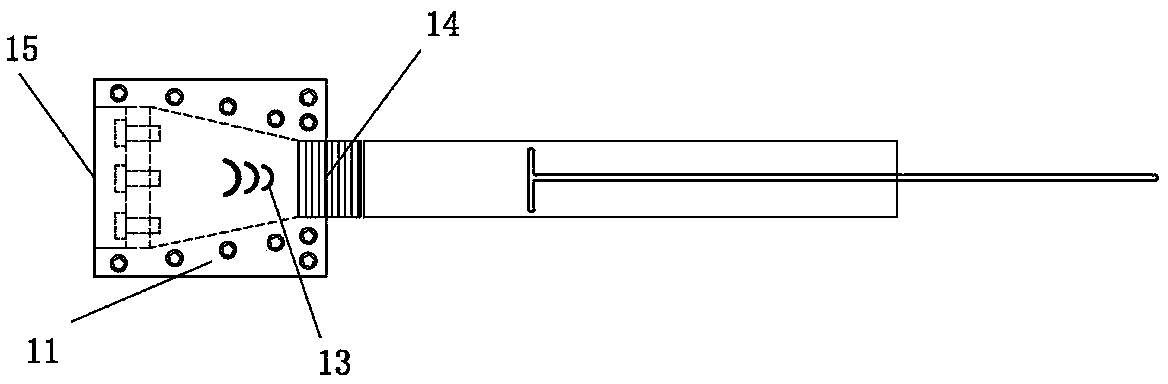

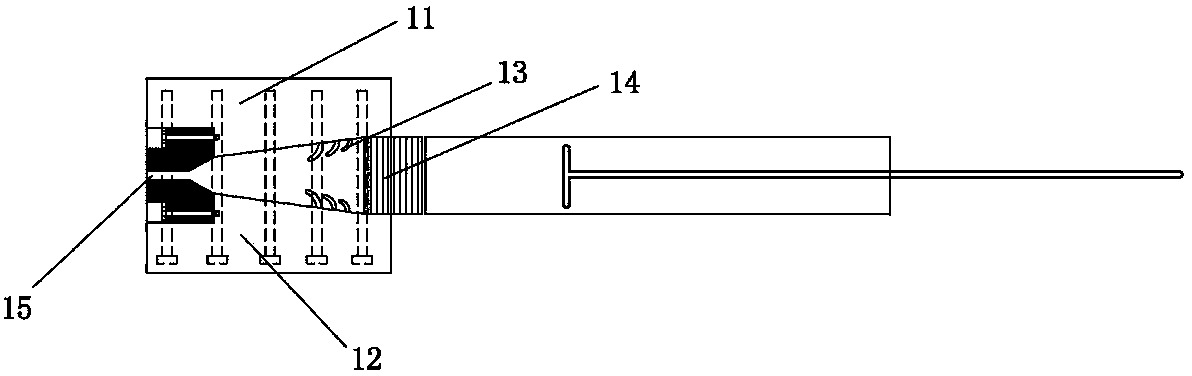

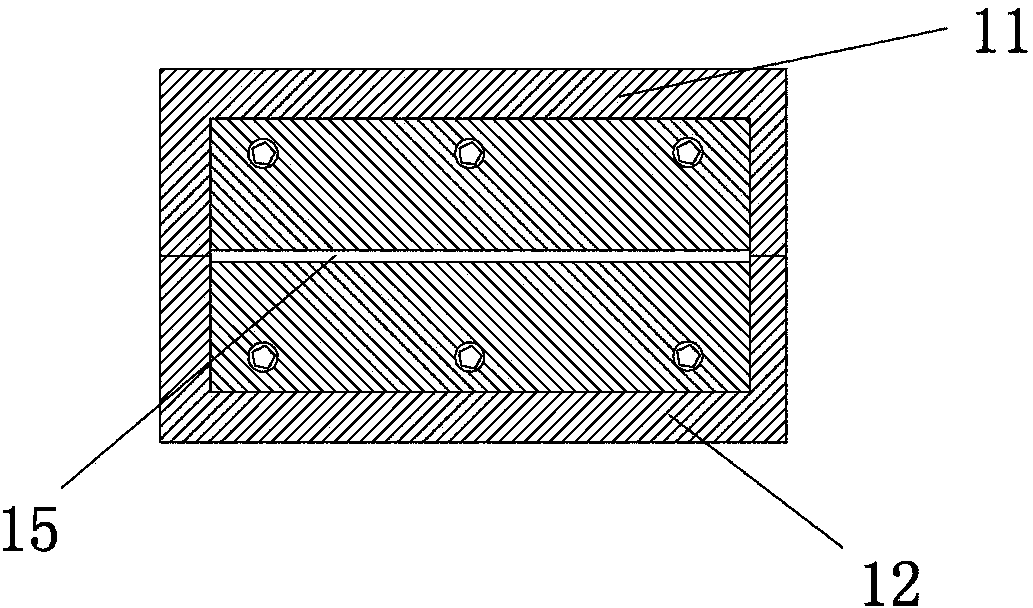

[0025] like Figure 1-5 As shown, a polytetrafluoroethylene raw material tape forming device is formed by connecting an upper body 11 and a lower body 12 by bolts, the upper body 11 and the lower body 12 are connected to form a cavity, and one end of the cavity is formed Cylindrical mouth 13, the other end of the cavity is formed into a "one"-shaped mouth 14; the upper body 11 and the lower body 12 are provided with flow blocking blocks 15 on the inner side surfaces. The blocking blocks 15 are arranged on the inner sides of the upper body 11 and the lower body 12; when the upper body 11 and the lower body 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com