A kind of plating solution and method of electroless pearl nickel plating

A technology of electroless plating solution and pearl nickel, which is applied in the direction of liquid chemical plating, metal material coating process, coating, etc., can solve the problems of monotonous preparation method of pearl nickel and uneven coating, and achieve low cost, uniform coating, The effect of high utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

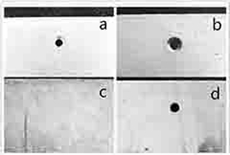

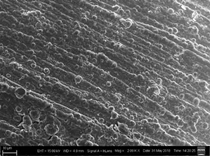

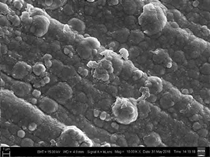

Image

Examples

specific Embodiment approach 1

[0018] Specific embodiment one: a kind of plating solution and the method of electroless pearl nickel plating of the present embodiment are carried out according to the following steps:

[0019] 1. Preparation of alkali washing solution: Dissolve sodium hydroxide, sodium phosphate, sodium silicate, sodium carbonate and sodium lauryl sulfate in deionized water and set aside;

[0020] 2. Preparation of pre-plating solution: Dissolve zinc oxide, zinc dihydrogen phosphate, phosphoric acid, citric acid, sodium fluoride, sodium dodecylbenzenesulfonate, and sodium molybdate in deionized water, and adjust the pH for later use;

[0021] 3. Preparation of chemical plating solution:

[0022] (1) Acidic chemical plating solution: Dissolve nickel sulfate, sodium hypophosphite, citric acid, anhydrous sodium acetate, sodium chloride, emulsifier OP-10, potassium iodate, and sodium dihexyl succinate sulfonate In deionized water, adjust the pH before use;

[0023] (2), alkaline chemical plati...

specific Embodiment approach 2

[0025] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that the alkali washing liquid degreasing process described in step 1 is to remove saponifiable grease through the saponification and emulsification of lye, and the mechanism of soaking and wetting to achieve degreasing The purpose of its alkaline lotion formula is sodium hydroxide 90g / L, sodium phosphate 30g / L, sodium silicate 20g / L, sodium carbonate 20g / L, sodium lauryl sulfate 0.02g / L, add deionized In water, dissolve it. Others are the same as the first embodiment.

specific Embodiment approach 3

[0026] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is that the formula and surface pre-plating process of the pre-plating solution described in step two are: preparing zinc oxide 12g / L, zinc dihydrogen phosphate 10g / L, 150ml solution of phosphoric acid 30mL / L, citric acid 0.5g / L, sodium fluoride 0.4g / L, sodium dodecylbenzenesulfonate 0.3g / L, sodium molybdate 1g / L in a 250mL beaker; Concentrated ammonia water was added dropwise to adjust the pH to 2.5. Finally, the activated steel sheet was immersed in the treatment solution for reaction. After 15 minutes of reaction, it was taken out, and the surface was rinsed with deionized water and dried for later use. Others are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com