Platform plate replacing slide suitable for flat digital ink-jet printing machine

A digital inkjet and printing machine technology, applied in typewriters, printing, printing devices, etc., to achieve the effect of high cost performance, simple device, and easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

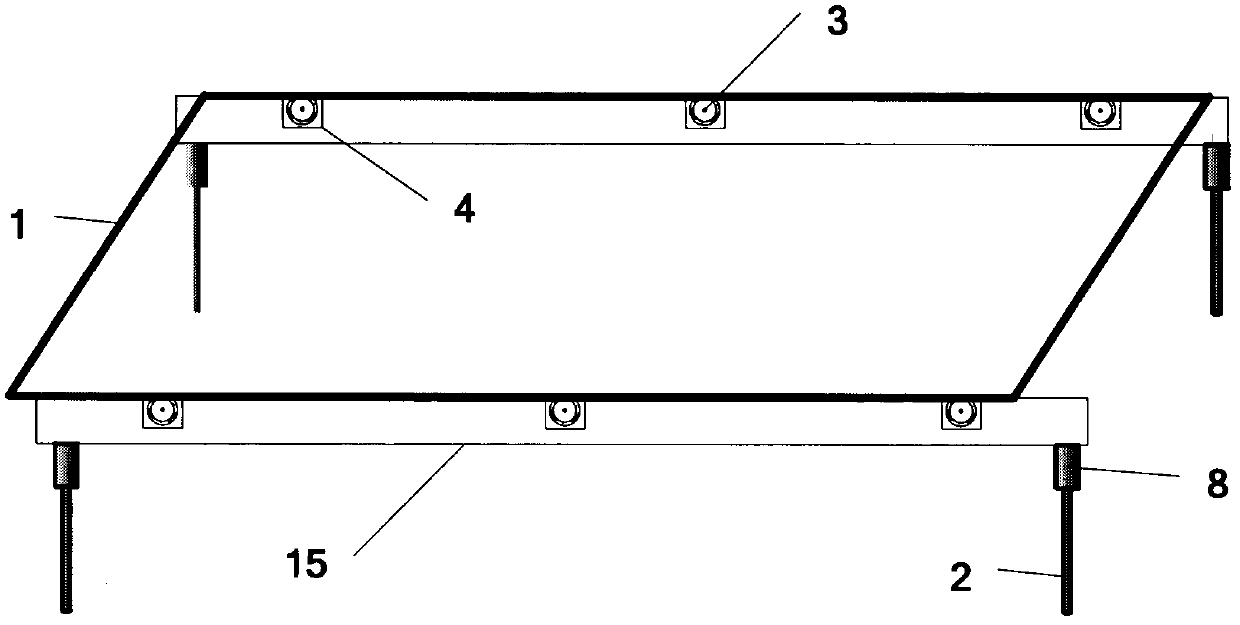

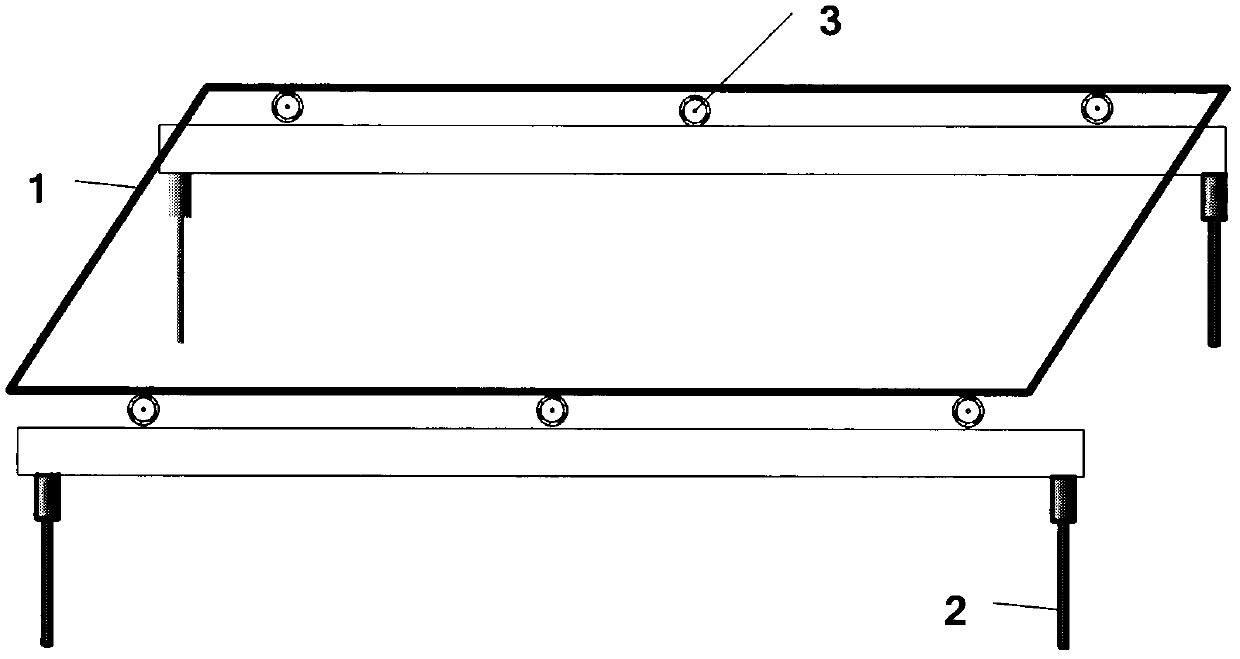

[0011] For the flatbed digital inkjet printing machine with mobile head, the printed fabric is placed on the printing flatbed (1) supported by the flatbed tray (10), and the four legs of the printing flatbed are respectively supported by four support rods (2), and the support rods There is a height adjusting screw (8) on it, so that the height of the support rod can be adjusted freely within a certain range. The machine head assembly (12) is connected on the ball screw (9) by a lead screw moving nut (14), so as to realize high-precision movement. When printing, at first, the nozzle group sub-car in the head assembly (12) runs a width distance in the fabric width direction to complete a lead; then the servo motor (13) controls the head assembly (12) in the fabric length direction Move forward along the high-precision ball screw (9) for a printing width, and this process is repeated until the printing of the entire fabric is completed.

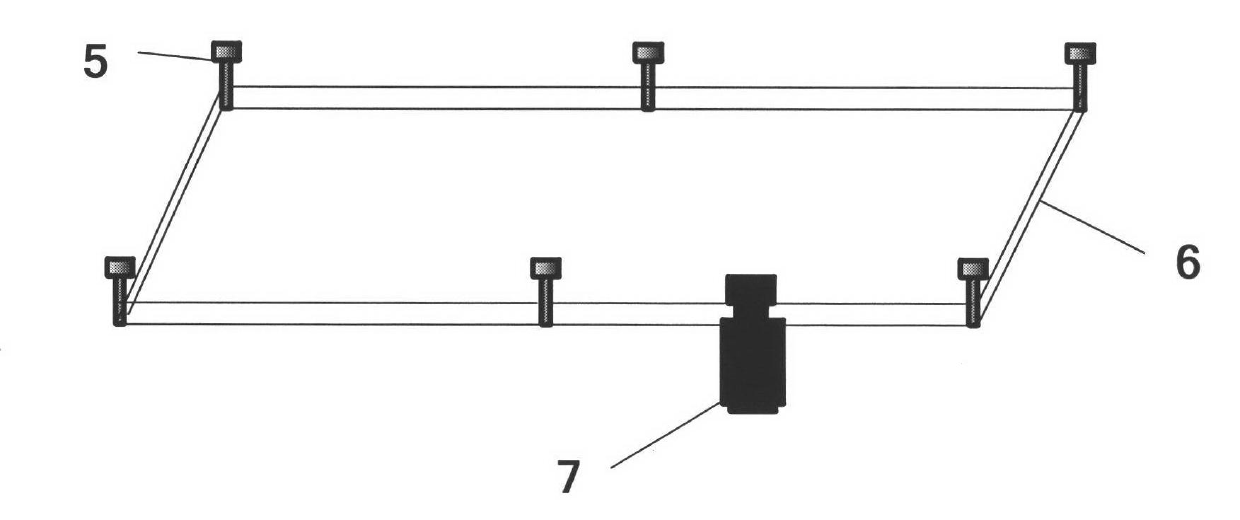

[0012] Depend on figure 1 As shown, six...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap