Method for recovering sulfate radicals from dechlorinated light salt brine to prepare anhydrous sodium sulfate

A technology of anhydrous mirabilite and light salt water, applied in alkali metal sulfite/sulfate dehydration, chemical instruments and methods, alkali metal sulfite/sulfite, etc., can solve the problem of large investment, large space occupation, equipment Corrosion and other problems, to achieve the effect of solving large steam consumption, saving steam consumption and preventing equipment corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

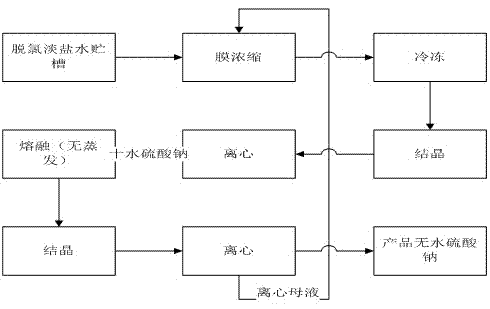

[0022] Such as figure 1 Shown, a kind of method that reclaims sulfate radical to produce anhydrous Glauber's salt from dechlorinated light brine comprises the following steps:

[0023] (1) Dilute dechlorinated light brine (NaCl: 200g / l; Na 2 SO 4 :8 g / l; Ca 2+ +Mg 2+ : 80ppm; NaClO: 0.08 ppm; NaCLO 3 : 8 g / l carries out membrane concentration, obtains concentrate, and the membrane adopted is nanofiltration membrane;

[0024] (2) Freezing and crystallizing the concentrated solution obtained in step (1), and centrifuging to obtain Glauber's salt;

[0025] (3) Put the Glauber's salt obtained in step (2) into the Glauber's salt heating circulation storage tank and add water to the upper circulation port, then heat and circulate through the heater through the circulation pump, and control the water temperature at 40°C. The conveying pump pumps the circulating liquid into the sodium sulfate decahydrate settling tank to settle, and starts the centrifuge to obtain the anhydrous ...

Embodiment 2

[0029] In this embodiment, the thermal melting temperature is controlled to be 50° C., and the rest are the same as in Embodiment 1. The production of 1 ton of anhydrous Glauber’s salt in this embodiment consumes 0.32 tons of steam in total.

Embodiment 3

[0031] In this embodiment, the thermal melting temperature is controlled to be 99° C., and the rest is the same as in the embodiment. The production of 1 ton of anhydrous Glauber’s salt in this embodiment consumes 0.4 tons of steam in total.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com