Sludge treatment system, sewage and sludge treatment system and sewage and sludge treatment method

A treatment system and sludge treatment technology, applied in water/sludge/sewage treatment, dehydration/drying/concentrated sludge treatment, water/sewage multi-stage treatment, etc. Centrifugal dewatering machine operating frequency changes and other problems, to reduce the impact, reduce the sludge moisture content, and stabilize the operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

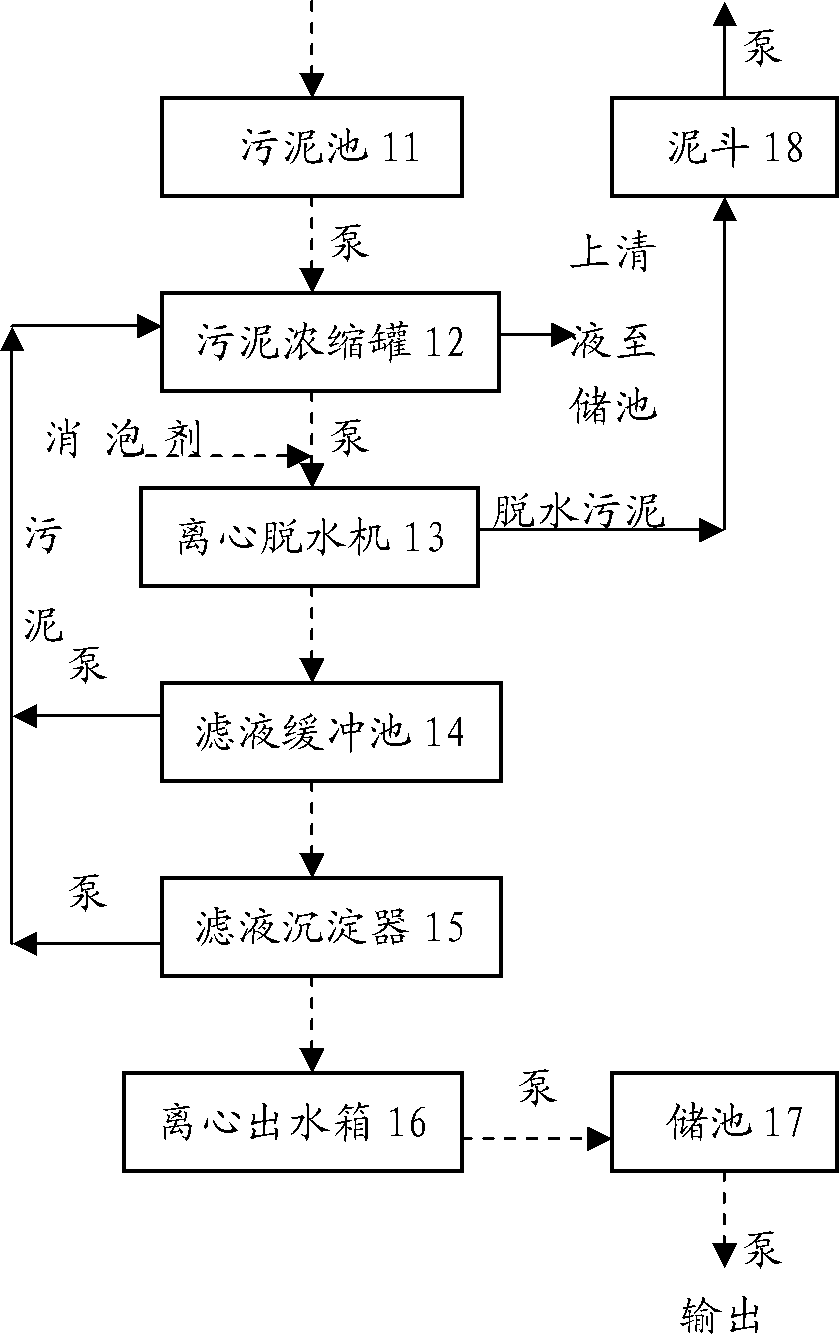

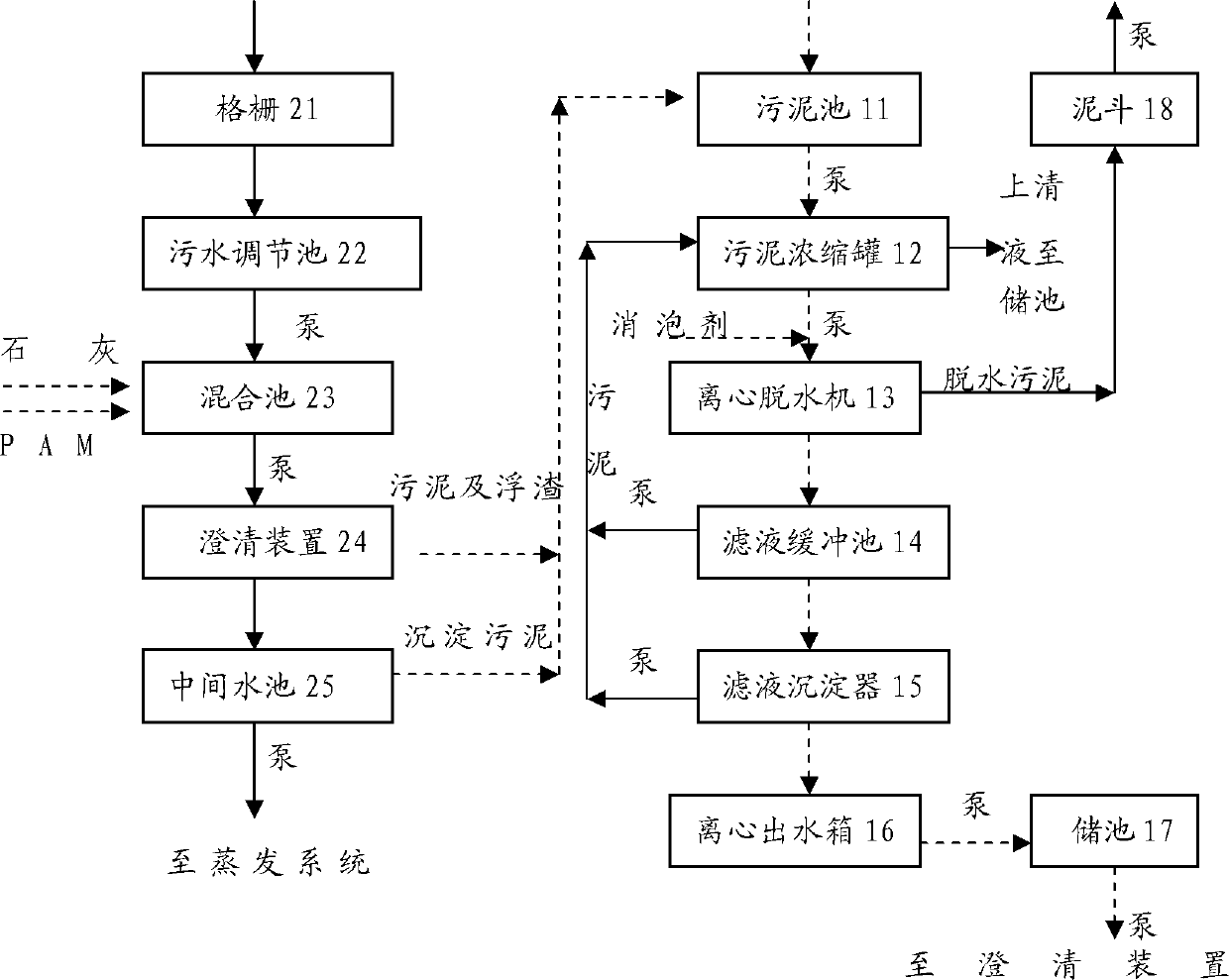

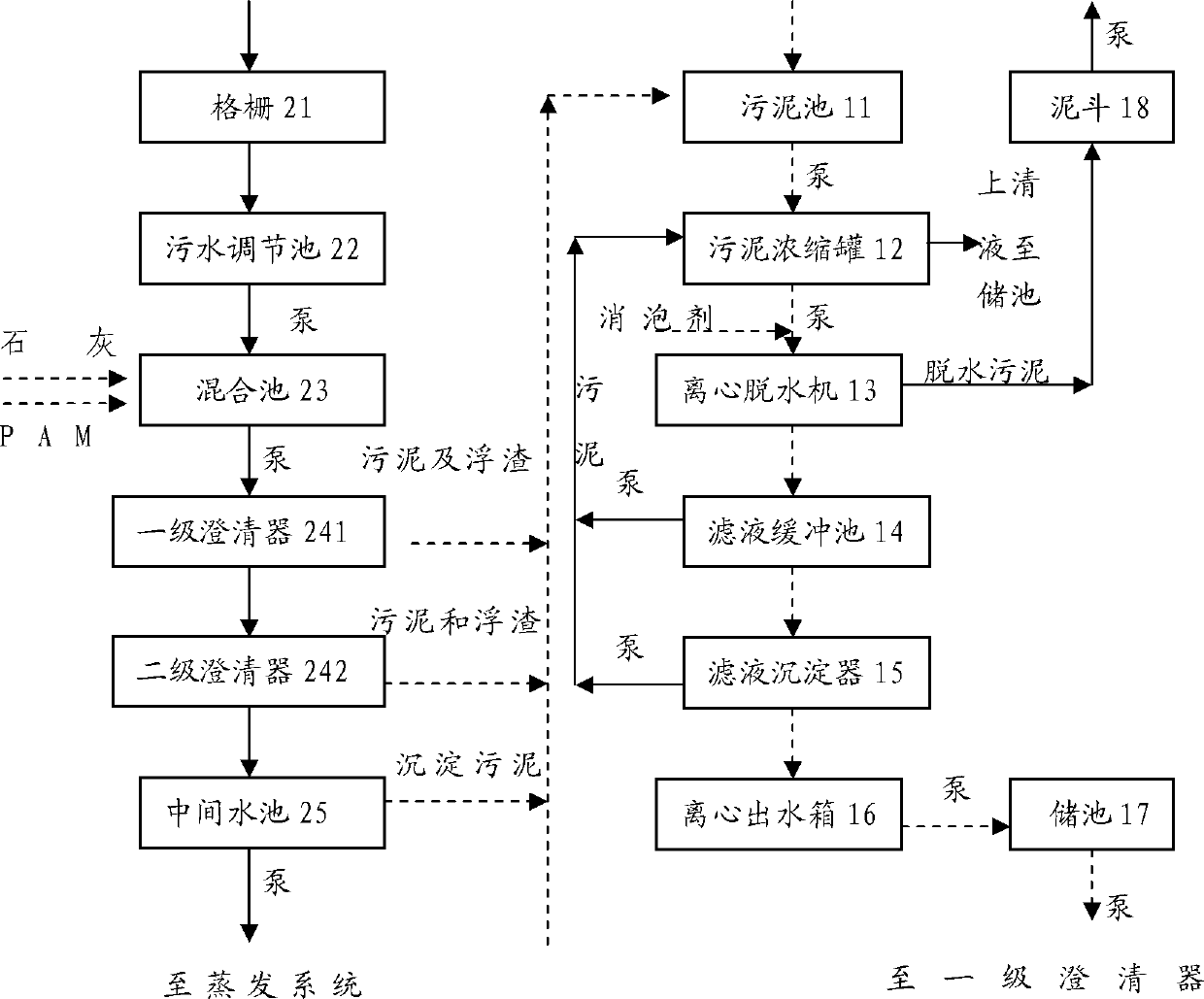

[0045] Such as figure 1 Shown is the first embodiment of the sludge treatment system of the present invention, which can be used for the evaporation raffinate after the evaporation treatment of the garbage leachate, the sludge and scum produced by the pretreatment of the leachate, etc.; of course, the sludge The treatment system can also be used for the treatment of other aqueous sludge.

[0046] As shown in the figure, the sludge treatment system includes a sludge tank 11, a sludge concentration treatment device, a dehydration treatment system, etc. connected in sequence; of course, it may also include a mud bucket 18, a storage tank 17, etc. connected to the dehydration treatment system.

[0047] The sludge pool 11 is connected to sludge, and a stirring device (such as a submersible mixer or others) can be set in the sludge pool 11 to stir and mix the sludge entering the sludge pool 11, and then pump it out to Sludge concentration treatment device. When the sludge is sent ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com