Hydrogen-storage alloy producing high-pressure hydrogen

A hydrogen storage alloy and high-pressure hydrogen technology, applied in the production of hydrogen and other directions, can solve the problems of difficult activation and low hydrogen storage capacity of the alloy, and achieve the effect of easy activation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The chemical formula of the hydrogen storage alloy is Ti 0.9 Zr 0.1 Ce 0.1 Cr 1.0 Fe 0.8 Mo 0.1 V 0.1 , Calculate the amount of each metal added according to the chemical formula. Among the raw materials, the purity of Ti, Fe, Ce, and Mo is 99.5%, and the purity of Zr, Cr, and V is 99.9%. After the above raw materials are cleaned and dried, they are weighed according to the calculated addition amount, placed in a water-cooled copper crucible of a magnetic levitation furnace, and smelted under the protection of 0.05MPa argon after being evacuated to a vacuum degree of 0.895 Zr 0.102 Ce 0.096 Cr 1.01 Fe 0.802 Mo 0.101 V 0.097 , which is consistent with the chemical formula of the designed hydrogen storage alloy.

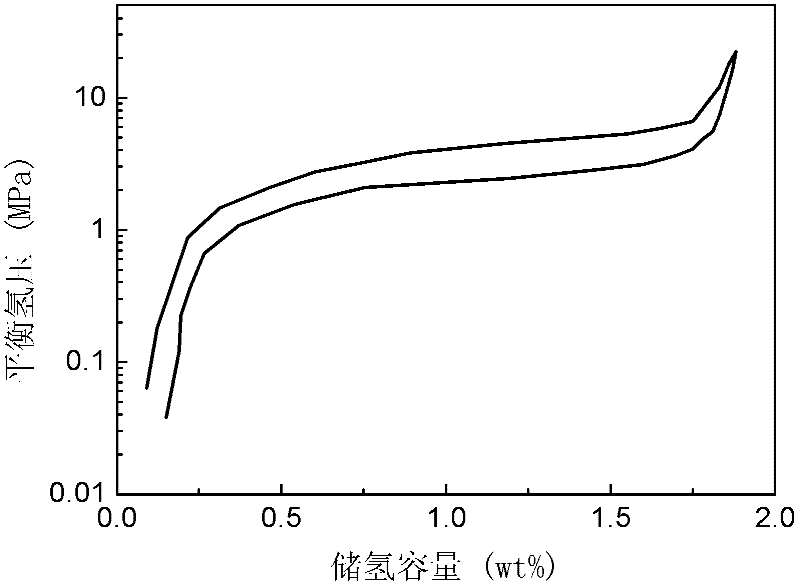

[0024] The hydrogen storage alloy ingot was taken out and broken into small pieces, and then put into the reactor for performance measurement. The hydrogen storage alloy does not require special activation treatment, and it is easy to absorb hydroge...

Embodiment 2

[0026] The chemical formula of the hydrogen storage alloy is Ti 0.95 Zr 0.05 La 0.05 Ce 0.05 Cr 1.3 Fe 0.8 V 0.2 , Calculate the amount of each metal added according to the chemical formula. Among the raw materials, the purity of La was 99.5%, and the purity of other metals was the same as in Example 1. After cleaning and drying, the raw materials are weighed according to the calculated addition amount, placed in a non-consumable electric arc furnace, evacuated to 0.13Pa, then smelted under the protection of 0.05MPa argon, and solidified and cooled in a water-cooled mold . In order to make the composition uniform, it needs to be smelted twice to obtain a hydrogen storage alloy. After chemical composition analysis, the chemical formula of the hydrogen storage alloy is Ti 0.945 Zr 0.051 La 0.0497 Ce 0.0496 Cr 1.30 Fe 0.802 V 0.197 , which is consistent with the chemical formula of the designed hydrogen storage alloy.

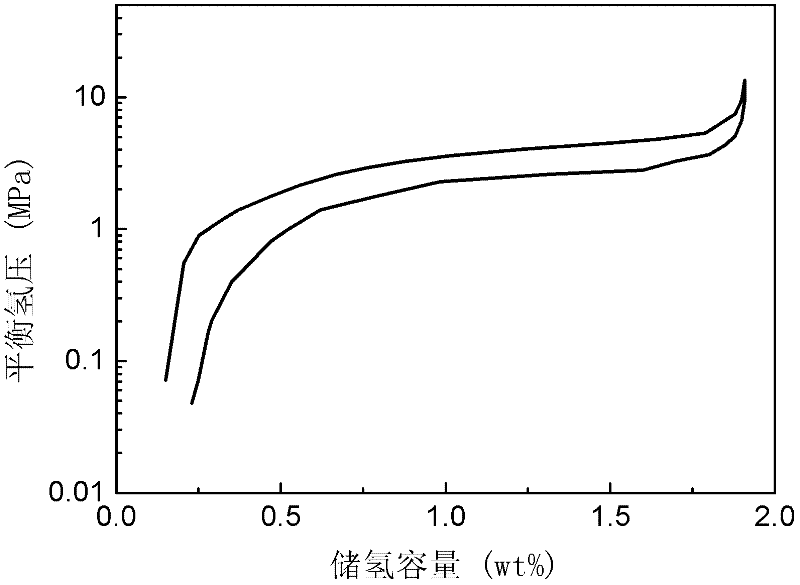

[0027] The method for measuring the propertie...

Embodiment 3

[0029] The chemical formula of the hydrogen storage alloy is Ti 0.7 Zr 0.3 La 0.05Cr 0.65 Fe 1.25 V 0.1 , Calculate the amount of each metal added according to the chemical formula. Raw material purity is the same as in Example 1 and Example 2. After cleaning and drying the raw materials, weigh them according to the amount added, and place them in the graphite crucible of the vacuum induction furnace. After evacuating and exhausting to a vacuum of 0.701 Zr 0.298 La 0.0498 Cr 0.649 Fe 1.250 V 0.098 , which is consistent with the chemical formula of the designed hydrogen storage alloy.

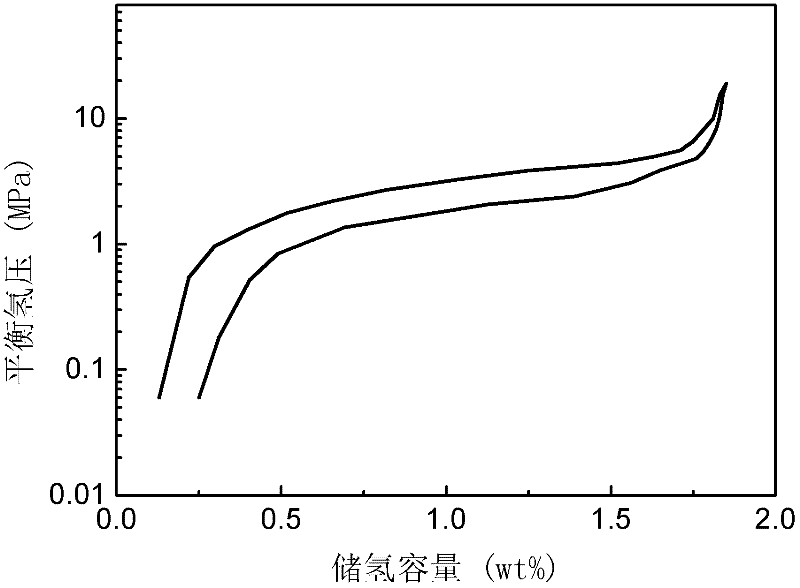

[0030] The performance measurement operation process of the hydrogen storage alloy is the same as that in Example 1. The P-C-T curve of the hydrogen storage alloy at 0°C is shown in image 3 . The hydrogen storage alloy does not require special activation treatment, and it is easy to absorb hydrogen when it comes into contact with 15MPa hydrogen for the first time (it starts to abso...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com