Tripping oil-return system for steam turbine for nuclear power station

A technology of oil return system and steam turbine, which is applied in the direction of detailed information of nuclear power plants, nuclear power generation, nuclear power plants, etc., and can solve problems such as malfunction, steam turbine shutdown by mistake, and lower reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

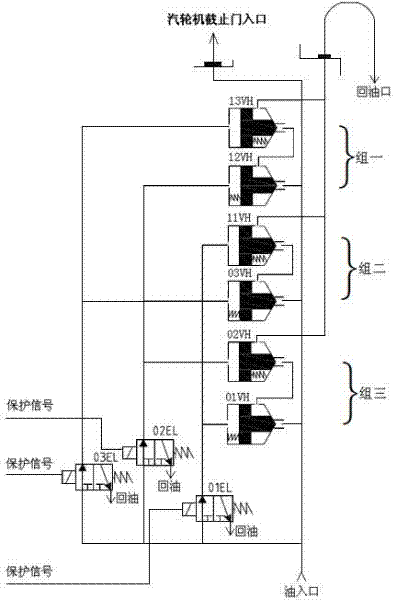

[0022] The present invention nuclear power plant steam turbine trip oil return system such as image 3 As shown, there are three groups of oil valves. Group 1 is oil valve 13VH connected in series with oil valve 12VH oil return chamber. Group 2 is oil valve 11VH connected in series with oil valve 03VH oil return chamber. Group 3 is oil valve 02VH and oil valve 01VH oil return chamber. The cavities are connected in series, and the oil return cavities between the three groups are connected in parallel.

[0023] There are three electronic control components, respectively using solenoid valves 01EL, 02EL and 03EL. The connection between the solenoid valve and the oil valve is as image 3 As shown, the solenoid valve 01EL controls the oil valve 11VH of group two and the oil valve 01VH of group three, the solenoid valve 02EL controls the oil valve 02VH of group three and the oil valve 12VH of group one, and the solenoid valve 03EL controls the oil valve 13VH and Oil valve 03VH of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com