Method for measuring warpage of electronic packaging product

A technology of electronic packaging and measurement methods, applied in electromagnetic measurement devices, electric/magnetic solid deformation measurement, etc., can solve the problems of high cost, inability to warp measurement, inconvenient use, etc., and achieve the effect of cost advantage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

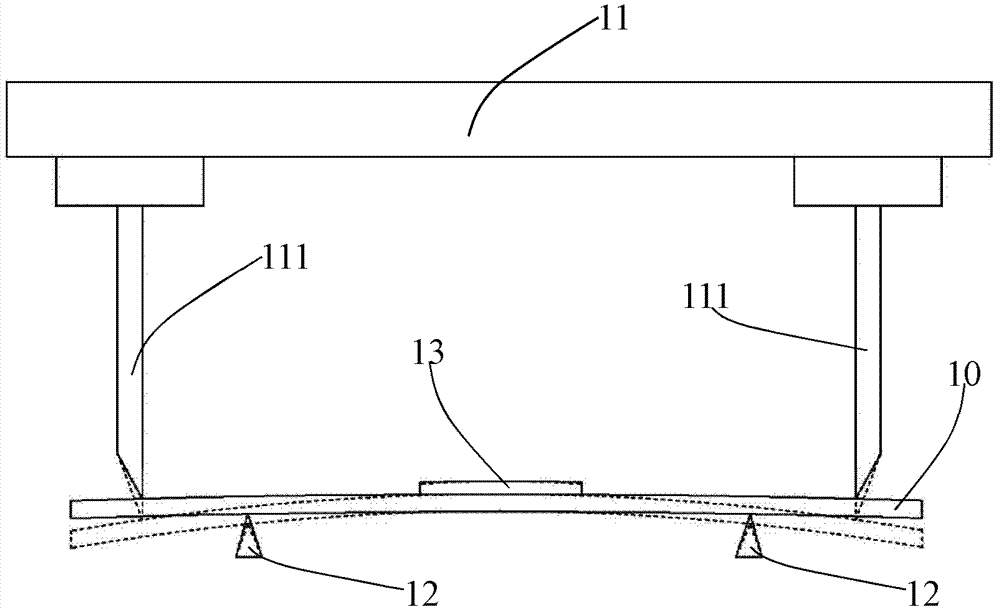

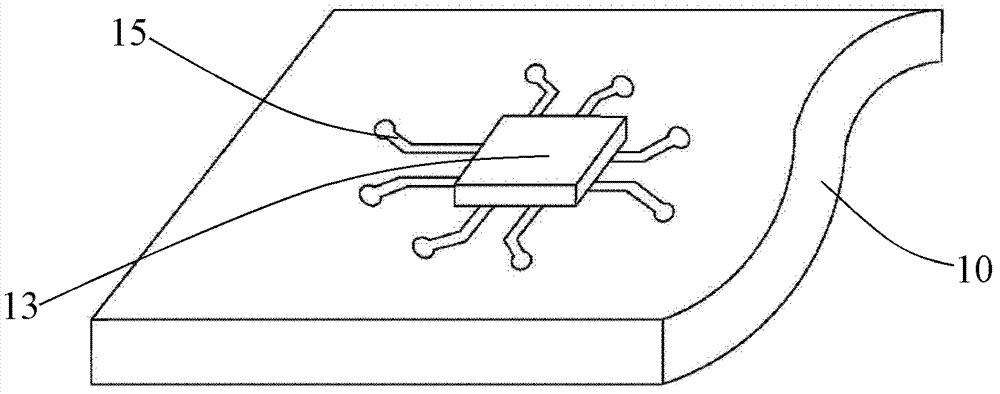

[0032] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

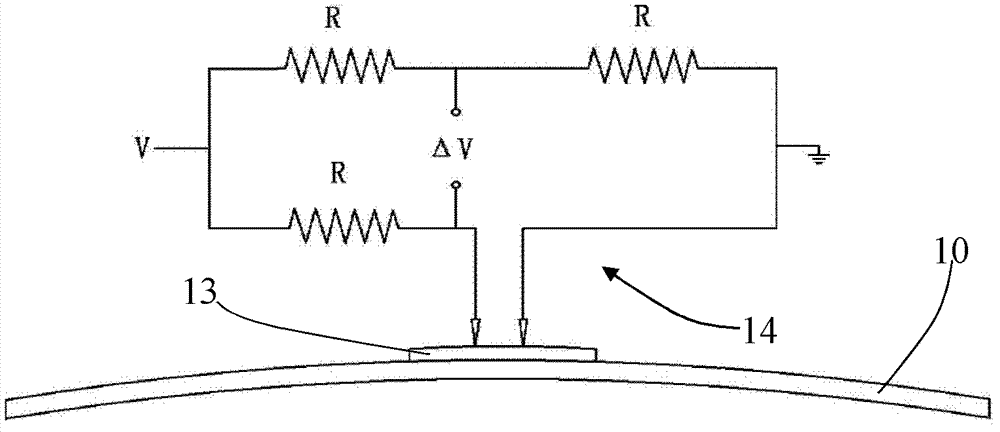

[0033] For the silicon stress sensor chip, when the chip itself is subject to a certain stress, the size of the piezoelectric resistance in the chip will change, so that the change of its stress can be obtained according to the change of its electrical parameters. Utilizing this characteristic of the silicon stress sensor, the warpage of the electronic packaging system can be quantitatively measured.

[0034] Use an adhesive to attach the silicon stress sensor chip to the surface of the product under test (such as a silicon wafer, a printed circuit board, etc.), and when the product under test warps to a certain extent, the stress sensor chip will also produce a corresponding deformation , so that in-plane normal stress and shear force are generated inside the chip. The magnitude of these additional normal stresses and shearing forces can be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com