Device for detecting blade strain on line based on optical fiber grating

A fiber grating and detection device technology, which is applied to measurement devices, optical devices, instruments, etc., can solve the problems of difficulty in online monitoring, poor stability, and vulnerability to lightning strikes, and achieve quasi-distributed measurement and high long-term stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

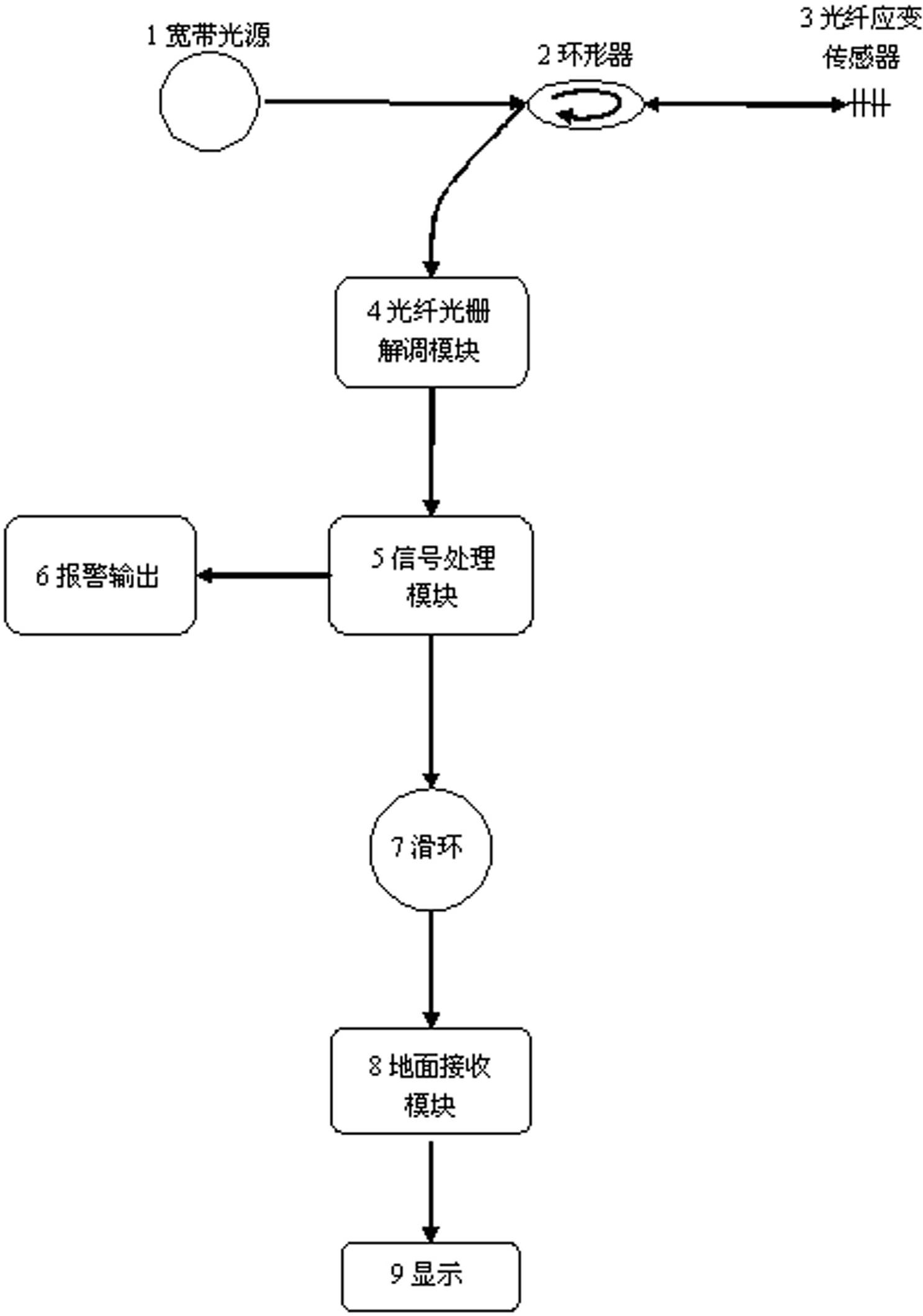

[0028] Such as figure 1 As shown, a fiber grating-based on-line fan strain detection device includes a broadband light source 1, a circulator 2, a fiber grating strain sensor 3, a fiber grating demodulation module 4 that converts optical signals into electrical signals, and converts electrical signals into The signal processing module 5 of the strain information, the slip ring 7, the ground receiving module 8, the output end of the broadband light source 1 is connected with the input end of the circulator 2 through an optical fiber, and the output end of the circulator 2 is connected with the fiber grating strain sensor 3 The input end of the circulator 2 is connected through an optical fiber, and the return end of the circulator 2 is connected with the input end of the fiber grating demodulation module 4 through an optical fiber;

[0029] The output end of the fiber grating demodulation module 4 is connected to the input end of the signal processing module 5 through a wire, a...

Embodiment 2

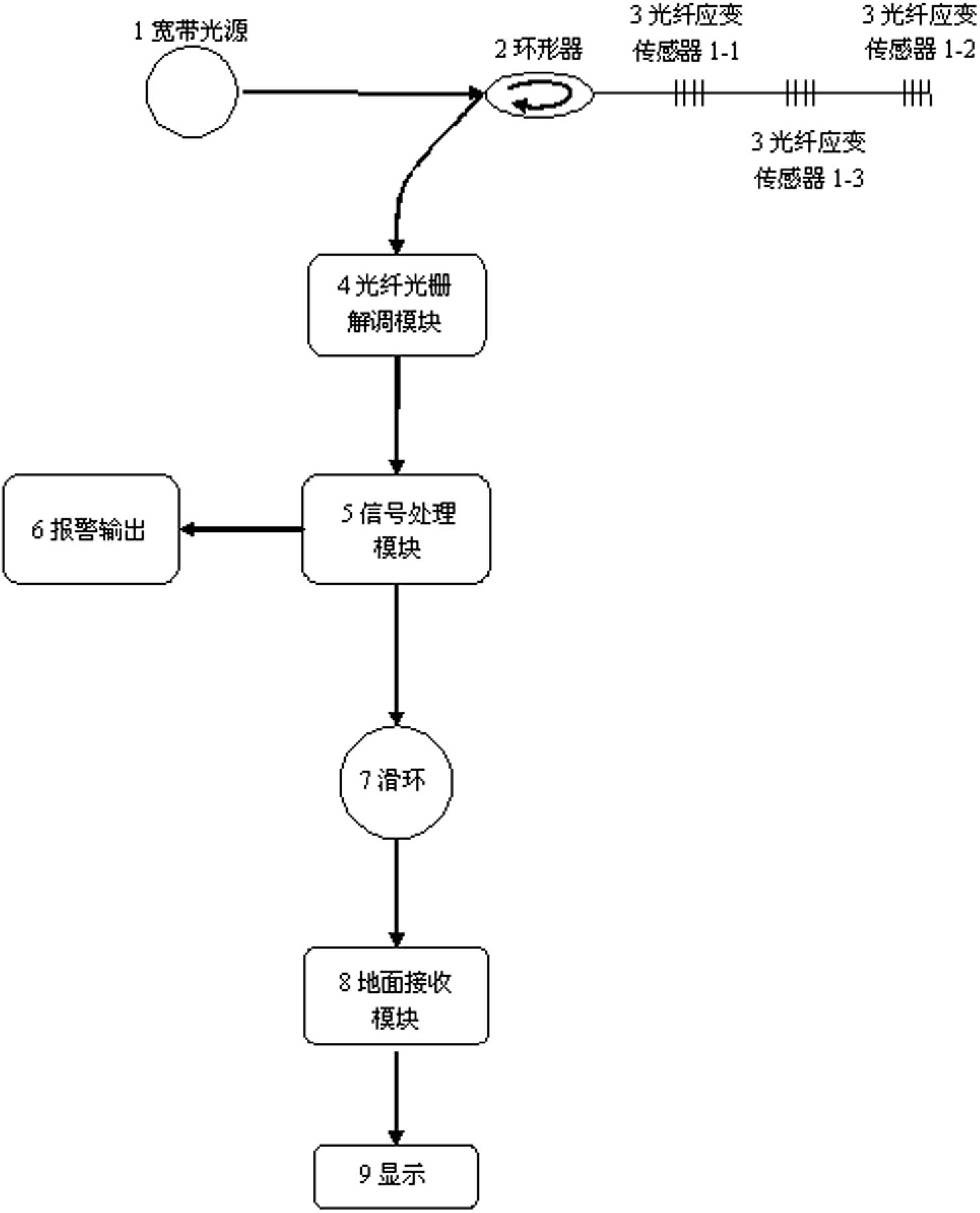

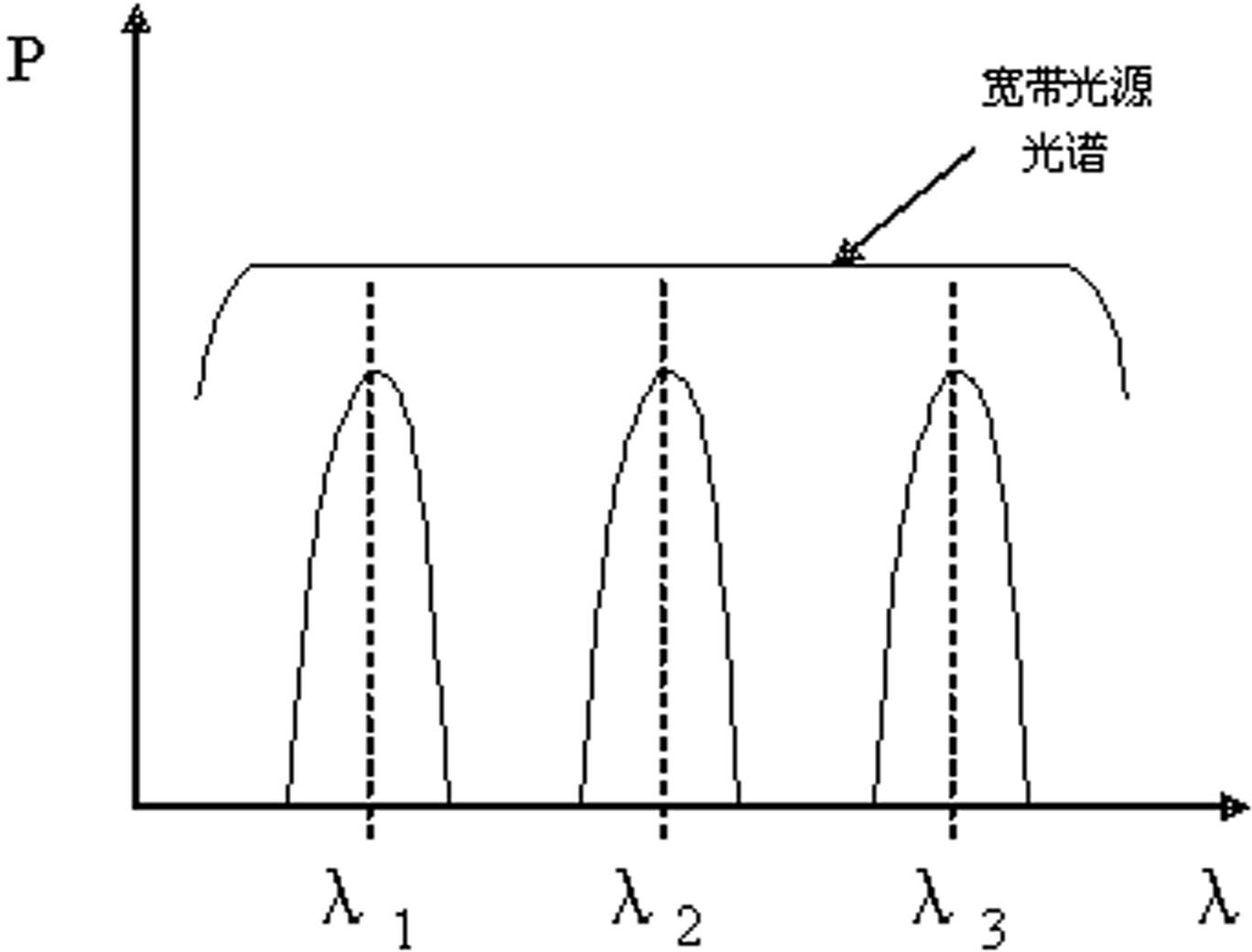

[0037] Such as figure 2 As shown, the difference between embodiment 2 and embodiment 1 is that it includes 3 fiber grating strain sensors 3. The number of fiber grating strain sensors 3 is equal to the quotient of dividing the spectral width of the broadband light source 1 by the spectral width of a single sensor. When the result is a decimal, keep the integer part and discard the decimal part. Three grating fiber optic strain sensors 3 are connected in series from end to end, using wavelength division multiplexing technology, such as image 3 As shown, measure multiple detection points of the blade to realize the quasi-distributed measurement of the blade strain; or through a splitter connection, the input end of the splitter is connected to the output end of the circulator 2, and each FBG strain The input ends of the sensors 3 are all connected to an output end of the splitter, and the broadband light emitted by the broadband light source 1 is transmitted to the FBG strain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com