Detection method of dynamic micronic dust in etching reaction chamber

A pollution state and detection method technology, which is applied in the direction of optical testing of defects/defects, discharge tubes, electrical components, etc., can solve problems such as inability to respond to etching reaction chambers in real time, affect process performance and product pass rate, and achieve the effect of reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

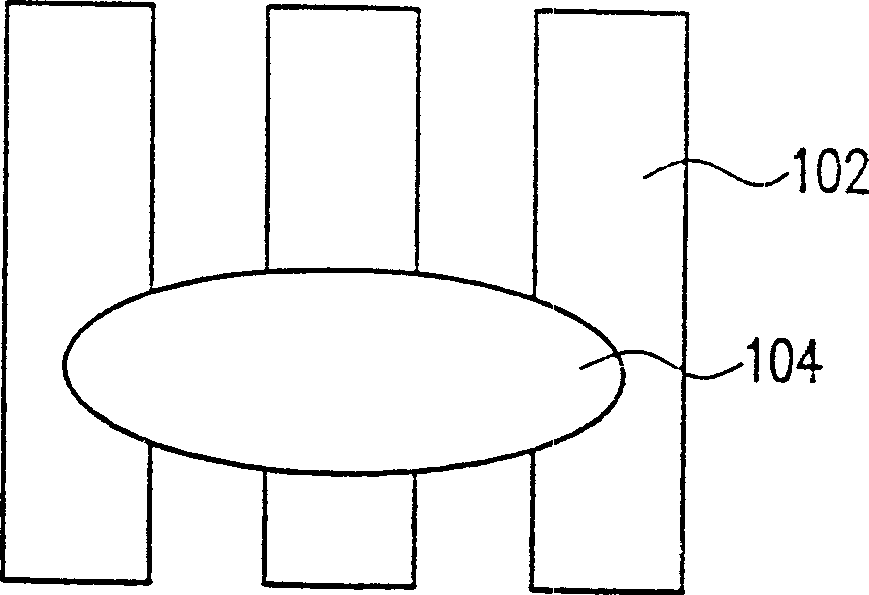

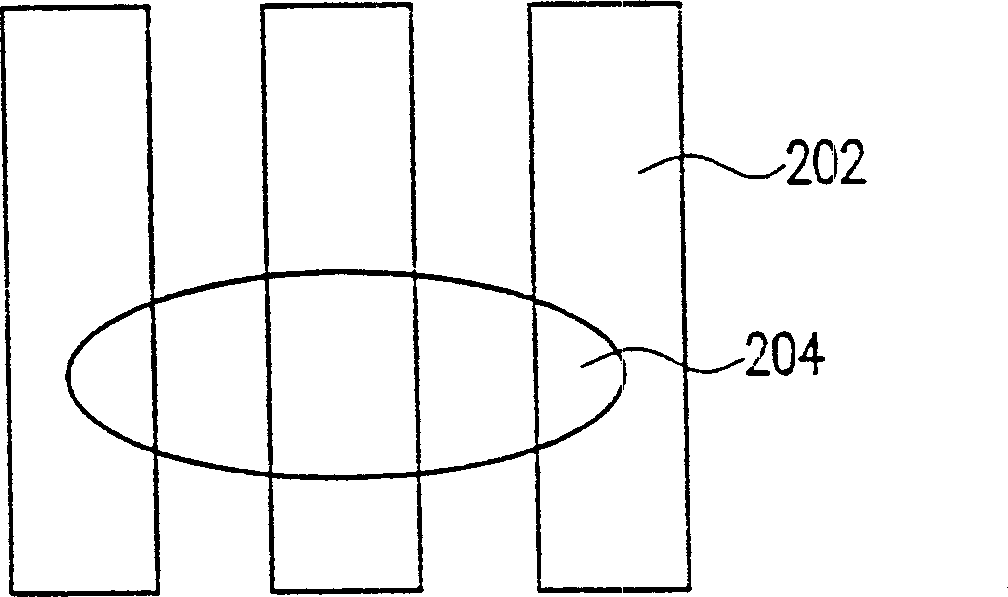

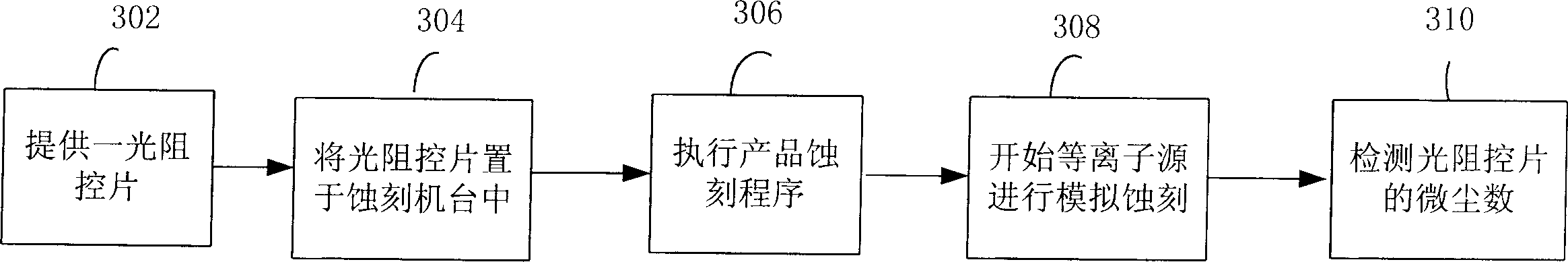

[0018] The invention uses the photoresist control sheet to simulate the conveying process of the actual production of the product in the etching process, and actually executes the production etching program, which can effectively simulate the situation that the product is polluted by fine dust in the etching reaction chamber during the actual production .

[0019] The following is to disclose preferred embodiments of the present invention, and please refer to the accompanying drawings for a detailed description. Before carrying out the method for detecting the dynamic fine dust pollution state of the etching reaction chamber disclosed in the present invention, the product is placed in a defect inspection machine to check the amount of fine dust. If the amount of fine particles on the product exceeds a certain value, there will be problems with the product. And the product is placed in a scanning electron microscope (Scanning Electron Microscope, SEM) to check the state of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com