Motorcycle frame rigidity performance test device

A test device, motorcycle technology, applied in the direction of measurement device, vehicle test, machine/structural component test, etc., can solve the problems of unfavorable new products, permanent deformation, difficult working conditions, etc., to solve the problem of frame strength and The needs of stiffness performance test evaluation, the effect of simple and reasonable structure and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

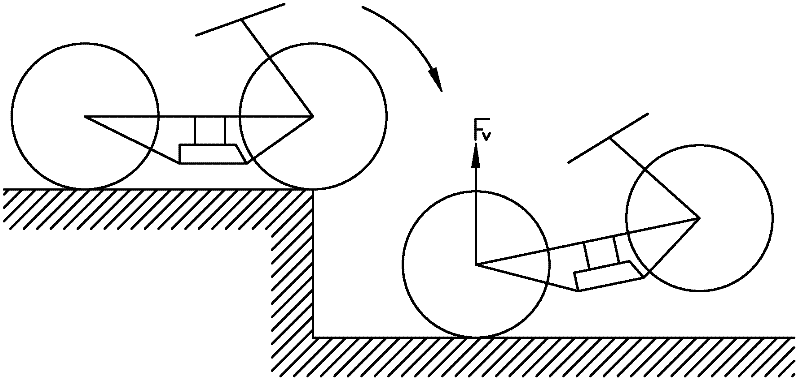

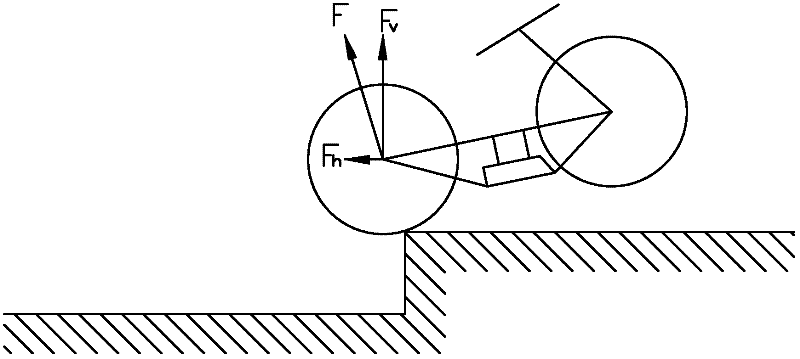

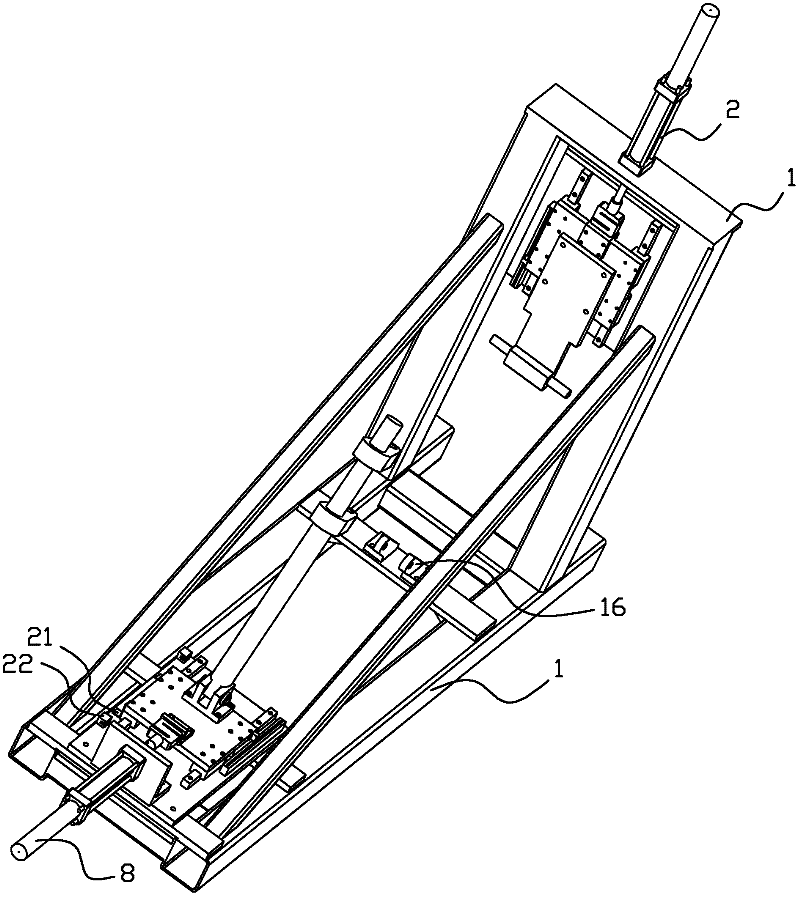

[0026] refer to Figure 3~Figure 9 , a motorcycle frame stiffness performance testing device of the present invention, which comprises a base 1, a vertical pressure cylinder 2 is fixed on the vertical frame of the base 1, and the vertical pressure cylinder 2 is used to generate a motorcycle frame 24 to be tested. The road simulates the vertical pressure; the end of the piston rod of the vertical pressure cylinder 2 is connected with the rear pressure plate seat 4 for directly applying the simulated vertical pressure to the motorcycle support 24, preferably, the vertical pressure cylinder 2 is connected with the rear pressure plate seat 4 through the vertical pressure sensor 3 , the vertical pressure sensor 3 is fixedly connected on the rear platen seat 4 through the vertical sensor support 31; the simulated vertical pressure produced by the vertical pressure cylinder 2 is transmitted to the rear beam 241 of the motorcycle frame 24 through the rear platen seat 4, and the rear pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com