Method for statically mixing raw materials for banding production line of sandwich panel

A sandwich panel and production line technology, applied in the direction of mixing methods, mixers, chemical instruments and methods, etc., can solve the problems of blocking discharge pipes, etc., and achieve the effect of fine cells and balanced and stable chemical reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

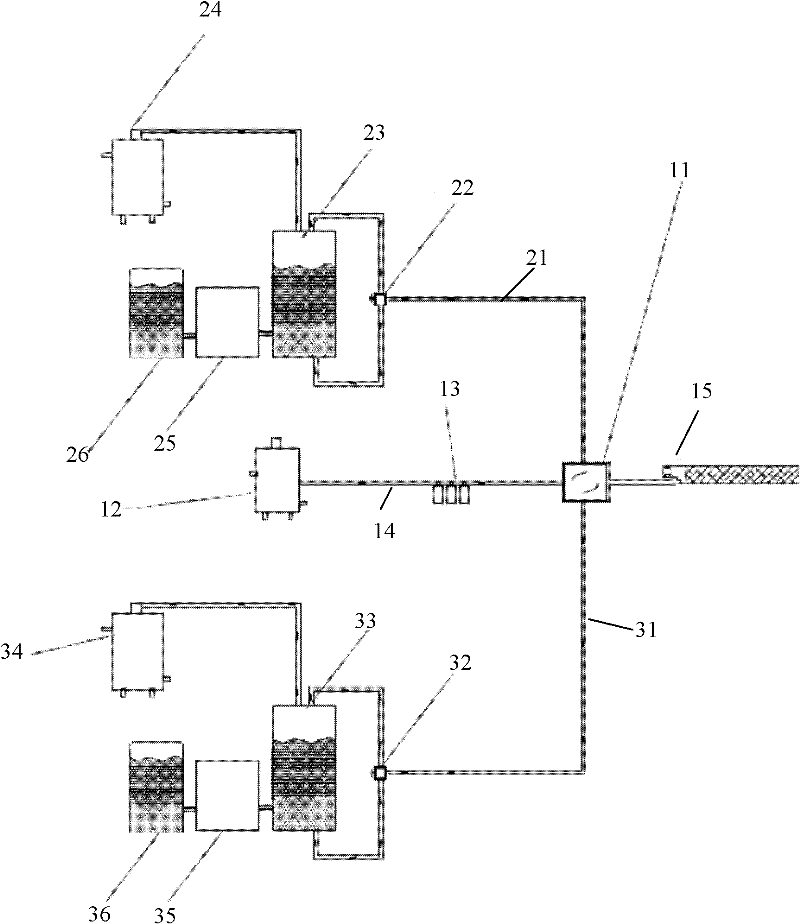

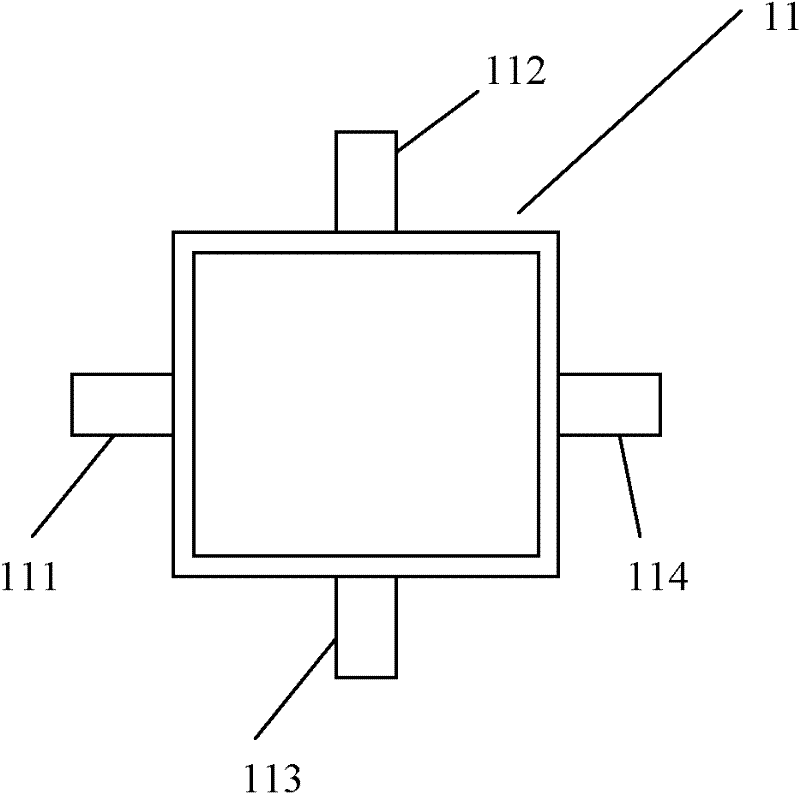

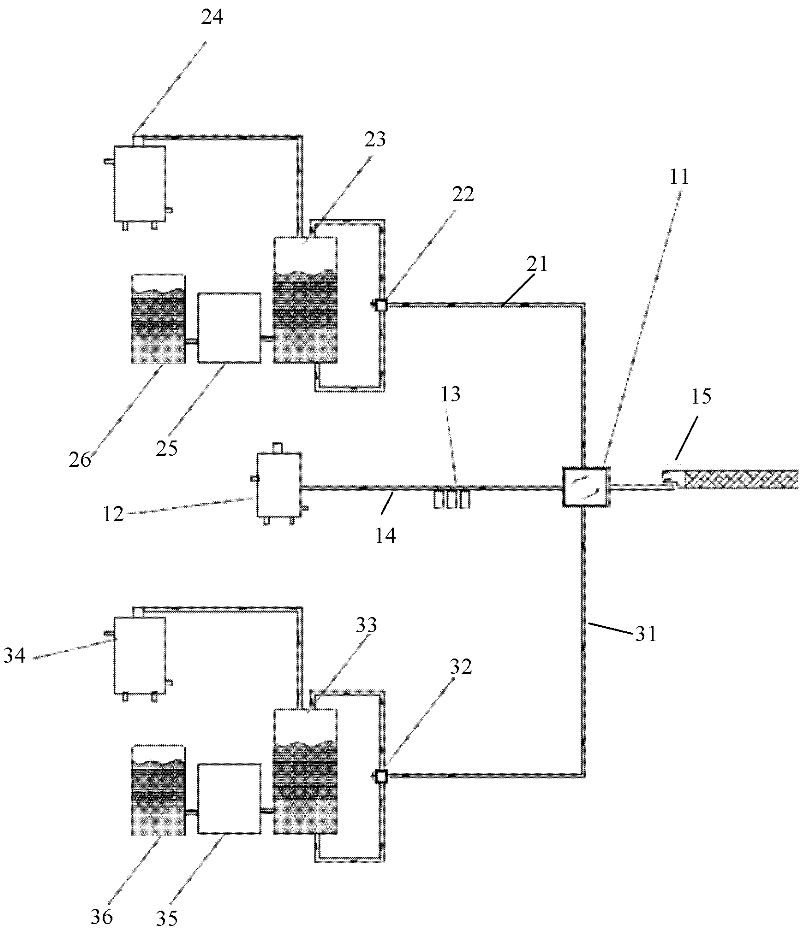

[0014] Such as figure 1 As shown, the static mixing device according to the embodiment of the present invention is arranged on both sides of the sandwich panel edge banding production line, figure 1 Taking the left side as an example, the working principle of the left and right sides is the same, including the raw material mixer 11, the air compressor 12, the air filter 13, and the air pipeline 14, the outlet of the raw material mixer 11 and the sandwich panel The position of sealing edge 15 is corresponding.

[0015] In addition, it also includes a first raw material pipeline 21, which communicates with the feeding pipeline of the first raw material tank 23 through a tee 22, and the first raw material tank 23 pumps the first raw material 26 into the raw material tank through the material pump 25, and passes the first raw material The air compressor 24 sends compressed gas into the first raw material tank, and sends the raw materials in the tank into the raw material mixer. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com