Design method of rhombic grid hole hot air grate sand core

A design method and grid hole technology, applied in the direction of cores, casting molding equipment, metal processing equipment, etc., can solve the difficulties in the processing and production of diamond-shaped core templates, the lack of versatility of hot blast furnace grate templates, and difficulty in meeting production requirements, etc. problem, to achieve the effect of low production cost, lower difficulty requirements, and control dumping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The specific implementation manner of the present invention will be described in detail below in conjunction with the accompanying drawings.

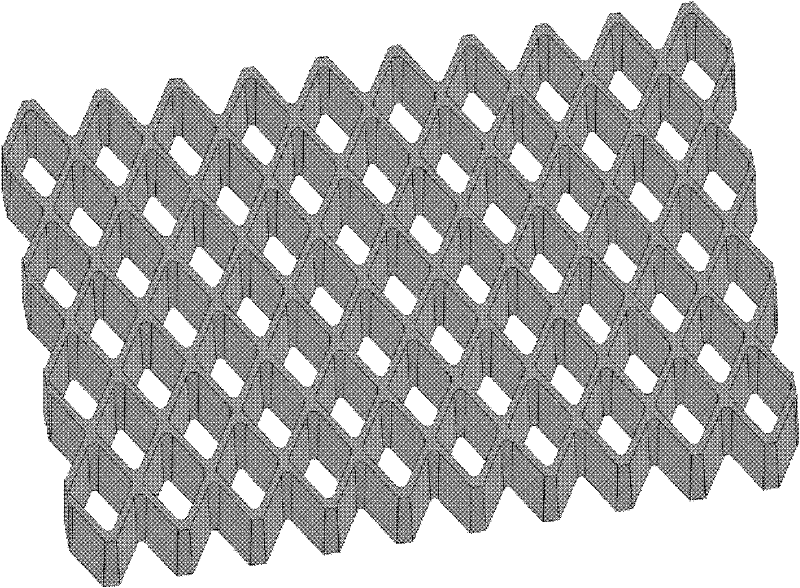

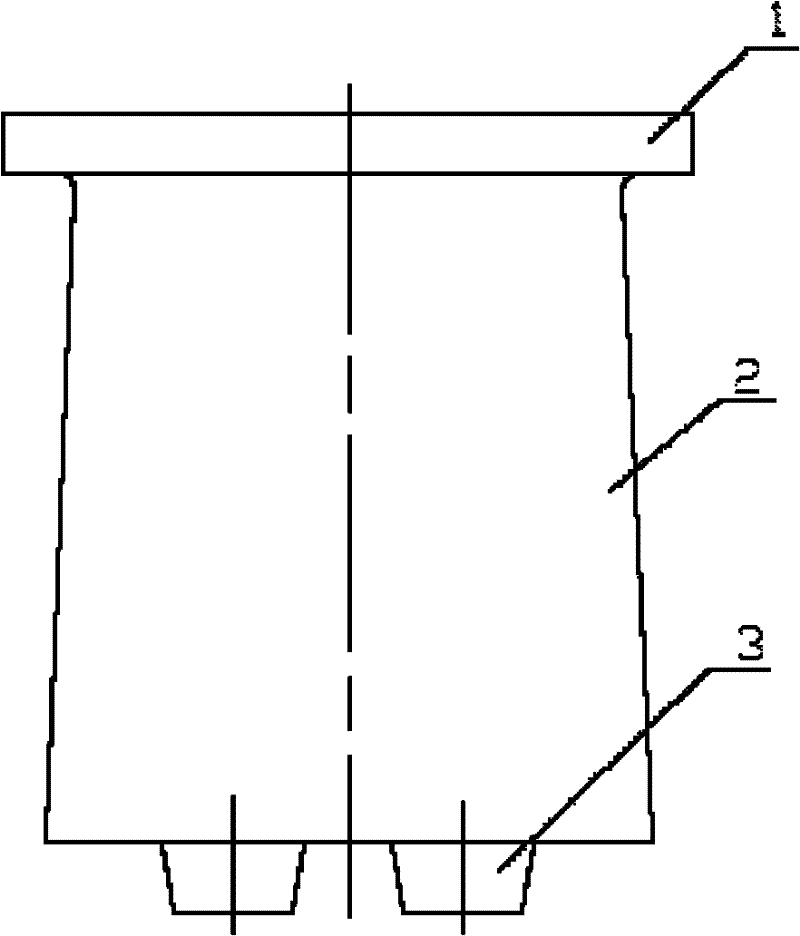

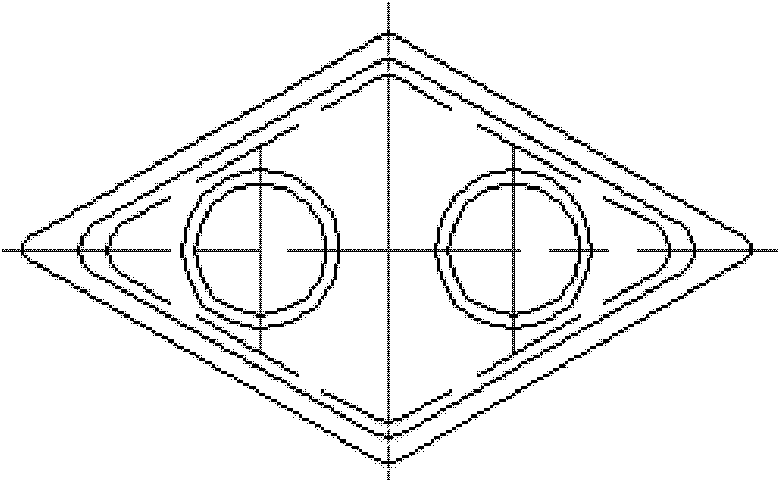

[0017] See figure 2 , image 3 , hot air grate sand core with rhombus grid holes, consisting of a plurality of sand core units, each sand core unit includes a lower core head 3, an upper core head 1, and a sand core body 2, and the lower core head 3 is double-conical truncated cone The core head, the sand core body 2 and the upper core head 1 are all diamond-shaped sand cores that combine two regular triangles into a whole; the lower core head 3 corresponds to the center of gravity of the two regular triangles of the upper core head 1 respectively. See figure 1 , is a hot blast furnace grate casting with rhombus mesh holes produced by hot air grate sand cores with rhombus mesh holes. Correspondingly, the core head sample of the porous core positioning general formwork used for modeling is also designed in the shape of a trunc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com