Method for improving mechanical property of FSW (friction stir welding) magnesium alloy joint

A friction stir and magnesium alloy technology, which is applied in welding equipment, non-electric welding equipment, metal processing equipment, etc., can solve the problems of reducing the mechanical properties of magnesium alloy friction stir welding joints and low joint strength, and achieves easy promotion, low cost, The method is simple and effective

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

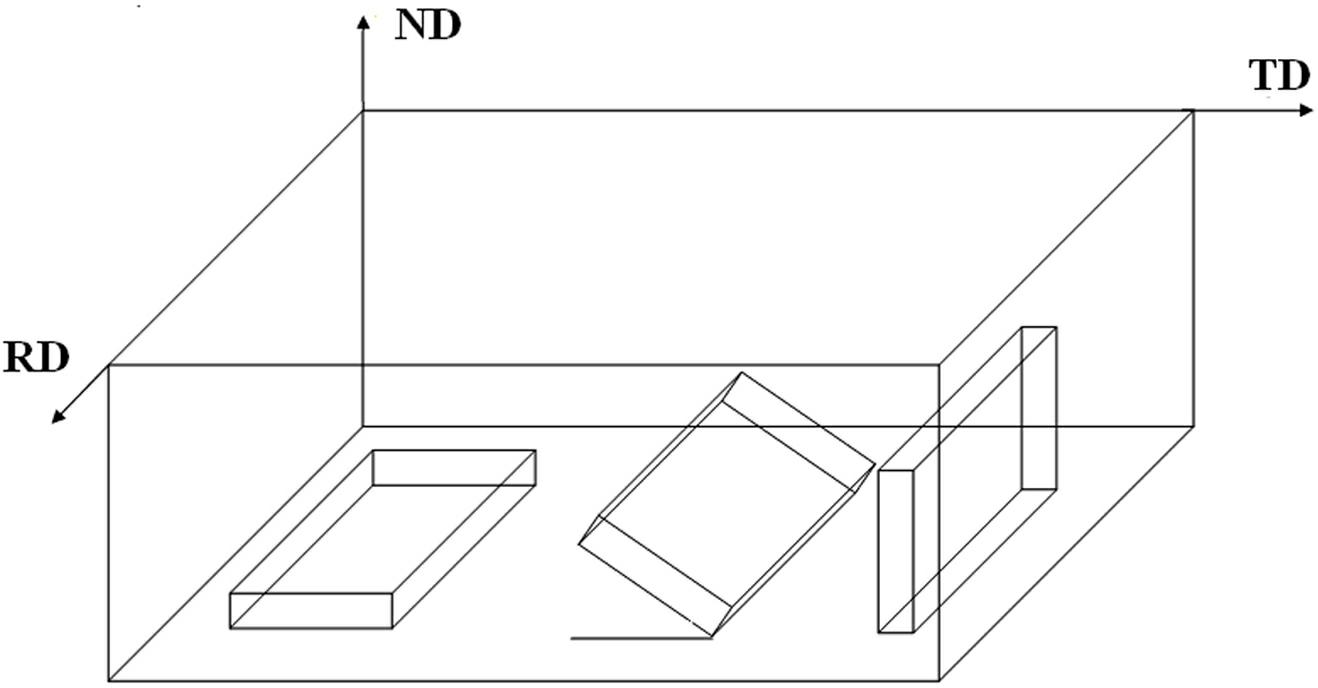

[0034] Select the AZ31 magnesium alloy plate 1 after rolling and finishing the grain orientation, the angle between its grain orientation and the horizontal plane of the magnesium alloy plate is 90 degrees, and the cut magnesium alloy plate 1 and the horizontal plane are 0 degrees, and the AZ31 magnesium alloy plate is obtained 2. Two pieces of AZ31 magnesium alloy plates 2 with a thickness of 6.0 mm were welded in a butt joint manner by friction stir welding. The diameter of the shoulder is 15 mm, the diameter of the stirring pin is 5 mm, the length is 5.7 mm, and the welding speed is 600 mm / min. The stirring head rotation speed was 1600 rpm. After testing, the welded magnesium alloy plate joints obtain a maximum tensile strength of 241Mpa, which is almost as strong as the base metal (243Mpa). The fracture occurs in the base material, and the welding bonding efficiency is 100%. The maximum elongation is 20.5%, which is less than the maximum elongation of the base metal, which...

Embodiment 2

[0036] Select the AZ31 magnesium alloy plate 1 after rolling and finishing the grain orientation, the angle between its grain orientation and the horizontal plane of the magnesium alloy plate is 90 degrees, and the angle between the cut magnesium alloy plate 1 and the horizontal plane is 45 degrees, and the AZ31 magnesium alloy plate is obtained 2. Two pieces of AZ31 magnesium alloy plates 2 with a thickness of 6.0 mm were welded in a butt joint manner by friction stir welding. The diameter of the shoulder is 15 mm, the diameter of the stirring pin is 5 mm, and the length is 5.7 mm. The welding speed is 600 mm / min, and the rotation speed of the stirring head is 1600 rpm. After testing, the maximum tensile strength obtained by the welded magnesium alloy plate joint is 212 Mpa, which is greater than the strength of the base metal (204 Mpa), the fracture occurs in the base metal, and the welding bonding efficiency is 100%. The maximum elongation is 35.5%, which is slightly lower ...

Embodiment 3

[0038] Select the AZ31 magnesium alloy plate 1 after rolling and finishing the grain orientation, the angle between its grain orientation and the horizontal plane of the magnesium alloy plate is 90 degrees, and the cut magnesium alloy plate 1 and the horizontal plane are 90 degrees, and the AZ31 magnesium alloy plate is obtained 2. Two pieces of AZ31 magnesium alloy plates 2 with a thickness of 6.0 mm were welded in a butt-joint manner by the friction stir welding method. The diameter of the shoulder is 15 mm, the diameter of the stirring pin is 5 mm, and the length is 5.7 mm. The welding speed is 600 mm / min, and the rotation speed of the stirring head is 1600 rpm. After testing, the maximum tensile strength obtained by the welded magnesium alloy sheet joint is 245 Mpa, which is slightly lower than the base metal strength (265 Mpa). The fracture occurs at the junction of the stirring zone and the thermomechanical affected zone on the forward side of the joint, and the welding b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com