On-line automatic tool setting and breakage detection device for minitype milling tool

An automatic tool setting and damage detection technology, which is applied in the direction of measuring/indicating equipment, metal processing machinery parts, metal processing equipment, etc., can solve the problems of size reduction, low reliability, and poor rigidity of micro tools, so as to prevent loss, Reliable measurement, fast detection of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

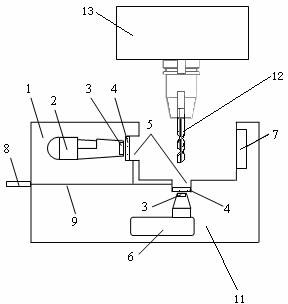

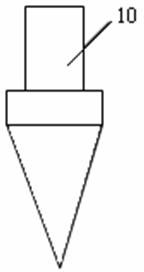

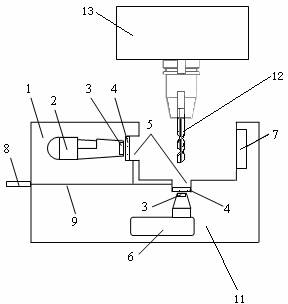

[0025] see figure 1 and figure 2 , an on-line automatic tool setting and damage detection device for micro milling cutters, comprising a housing 1, a device base 11, a tool optical detection system, a centralized control system and a tool wear alarm system, the device base 11 is fixedly installed on a machine tool with a tool 12 On the working table, the tool optical detection system is installed in the equipment cavity formed by the housing 1 and the device base 11. The tool optical detection system is fixed and installed on the device base 11 through the device bracket. The tool optical detection system is an area array image sensor system, the image data signal output end of the tool optical detection system is connected to the signal receiving end of the centralized control system, and the alarm command signal output end of the centralized control system is connected to the signal receiving end of the tool wear alarm system, which is characterized in that: the housing 1 ...

Embodiment 2

[0039] The technical solution of this embodiment is basically the same as that of Embodiment 1, the difference is that:

[0040] In this embodiment, the diffuse reflection backlight light source 7 is a strobe light source. Because the rotation speed of the micro milling cutter is very fast, the diffuse reflection backlight light source 7 can adopt a strobe light source to ensure that the image has good clarity.

Embodiment 3

[0042] The technical solutions of this embodiment are basically the same as those of Embodiment 1 and Embodiment 2, except that:

[0043] In this embodiment, the ring light source 3 is a strobe light source. Since the rotation speed of the micro-milling cutter is very fast, the ring light source 3 can adopt a stroboscopic light source to further ensure that the image has good clarity.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com