Glass fine grinding machine and grinding control method thereof

A technology for fine grinding machines and glass, which is applied to grinding automatic control devices, grinding machine parts, grinding/polishing equipment, etc. It can solve the problems of poor waterproof performance, complex trajectory design, and low work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Specific embodiments of the present invention are described with reference to the above drawings.

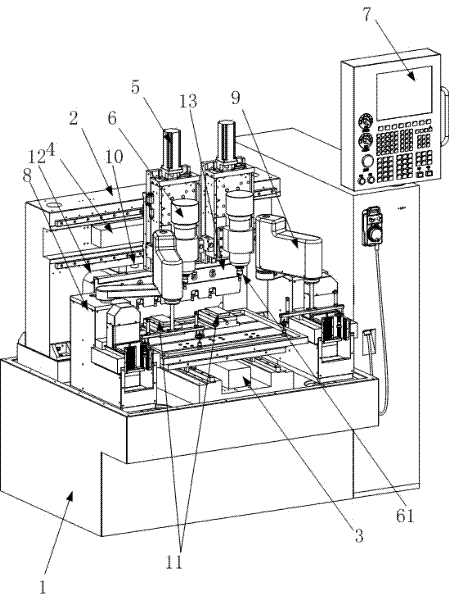

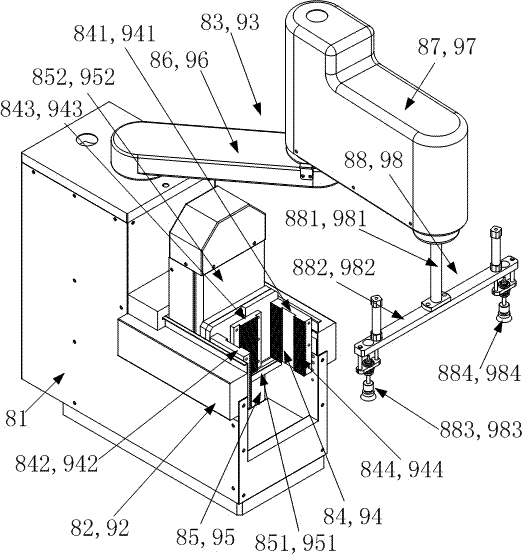

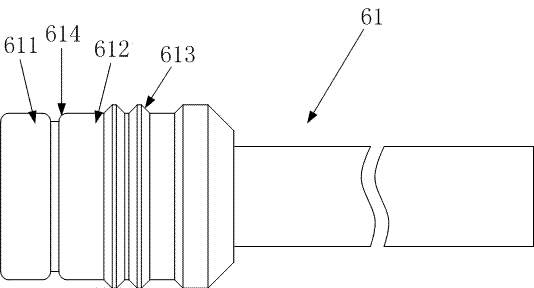

[0015] Depend on figure 1 It can be seen from the figure that this glass refiner includes a frame 1, a working platform 11 arranged on the frame 1, and a processing mechanism support 2, and a Y-axis adjustment mechanism 3 is arranged between the frame 1 and the working platform 11. The refiner also includes an X-axis adjustment mechanism 4 arranged on the processing mechanism support 2, a Z-axis feed mechanism 5 arranged on the X-axis adjustment mechanism 4, and a Z-axis feed mechanism arranged on the Z-axis feed mechanism 5. The grinding unit 6 and the control system 7 that controls the work of the above-mentioned various parts. The control system 7 is an industrial computer control system. The grinding unit 6 includes a tool holder 62 and a tool 61 clamped on the tool holder 62. The Y The shaft adjustment mechanism 3 is a linear motor drive mechanism, and the linear mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com