Assembly tool for connecting rod caps of engines

An engine connecting rod and assembly tooling technology, which is applied in the direction of manufacturing tools, workpiece clamping devices, hand-held tools, etc., can solve the problems of difficult manual assembly operations and narrow assembly space of connecting rod covers, so as to save cycle time and reduce production Cost, the effect of ensuring the reliability of the work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

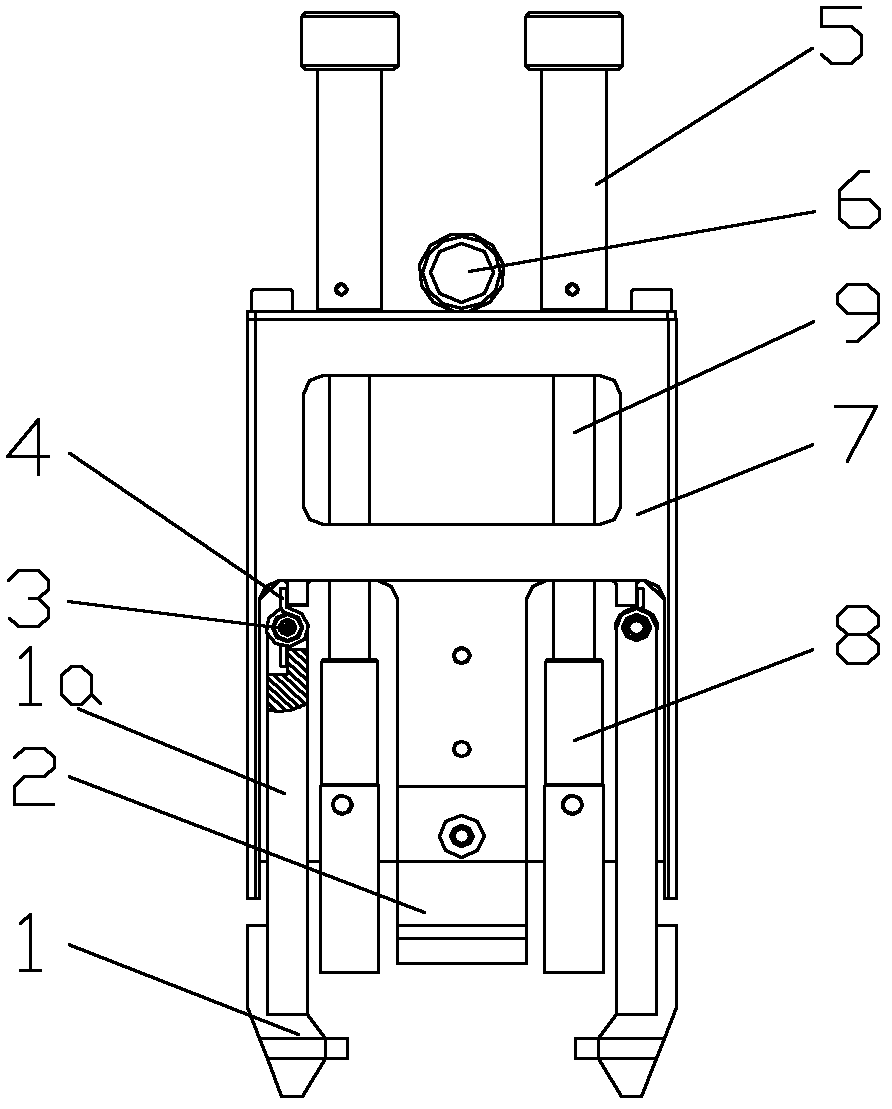

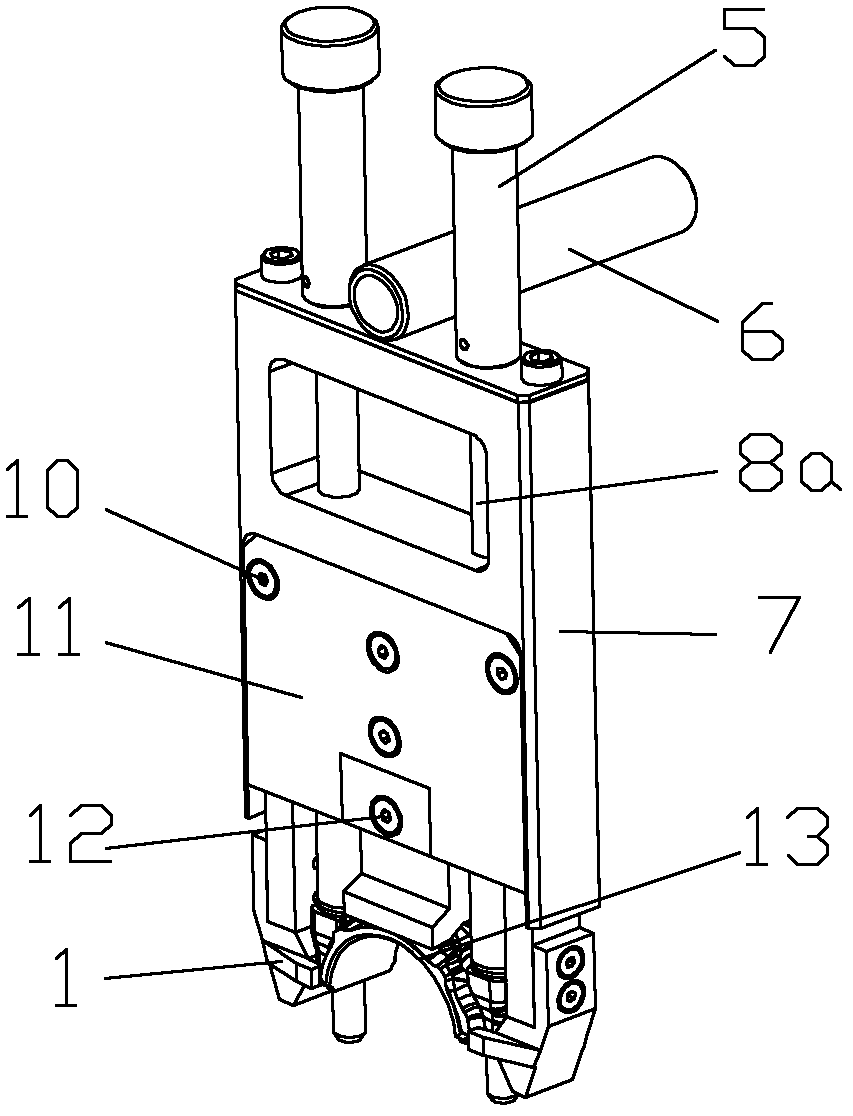

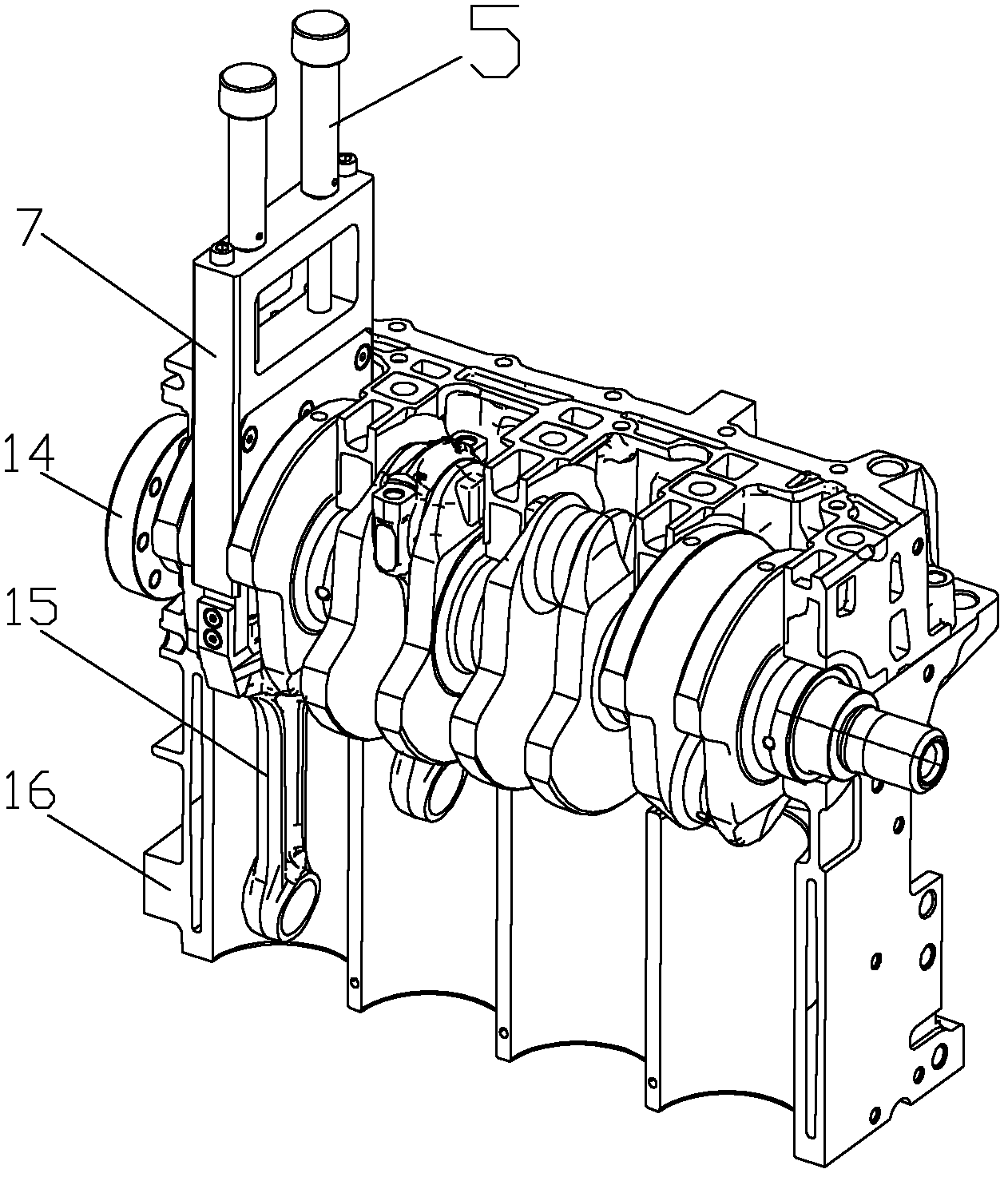

[0021] figure 1 It is a structural schematic diagram of the present invention, figure 2 It is a schematic diagram of the three-dimensional structure of the present invention, image 3 It is a schematic structural diagram of the installation process of the present invention, as shown in the figure: the engine connecting rod cover assembly tooling of this embodiment includes a frame 7, a clamping mechanism and a pretensioning mechanism arranged on the frame;

[0022] The clamping mechanism at least includes a jaw assembly for clamping and placing the connecting rod cover at a position corresponding to the installation position of the connecting rod; the pre-tightening mechanism at least includes a sleeve for pre-tightening the connecting bolts of the connecting rod cover 8. The length of the applying rod 9 of the sleeve 8 is at least longer than the crank of the crankshaft 14, that is, when the connecting rod is at the top dead center, the applying rod can extend out of the cr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com