Full-automatic vertical-horizontal multi-cutter combined edge cutting machine

A fully automatic and trimming machine technology, applied in the direction of stone processing tools, work accessories, manufacturing tools, etc., can solve the problems of low efficiency, long processing period, laborious and laborious, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

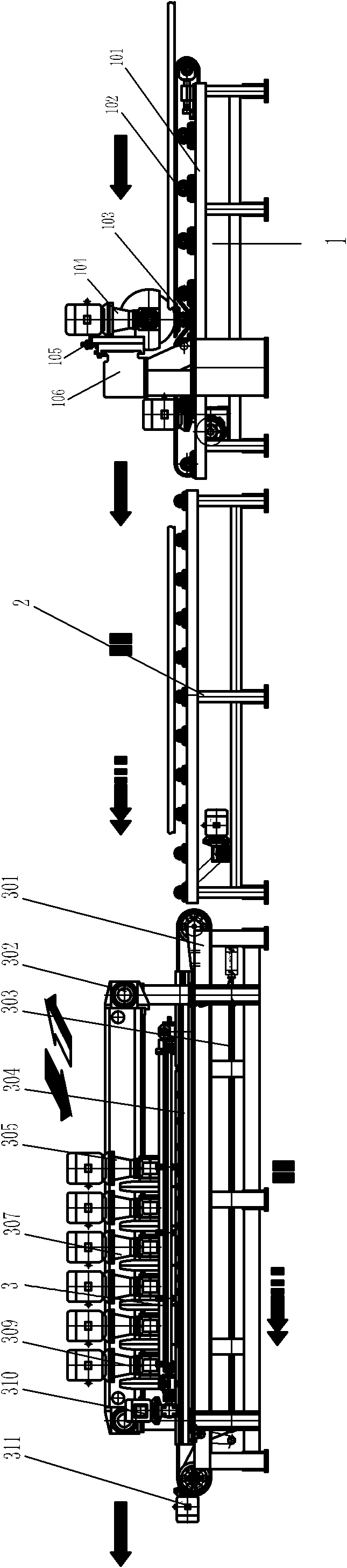

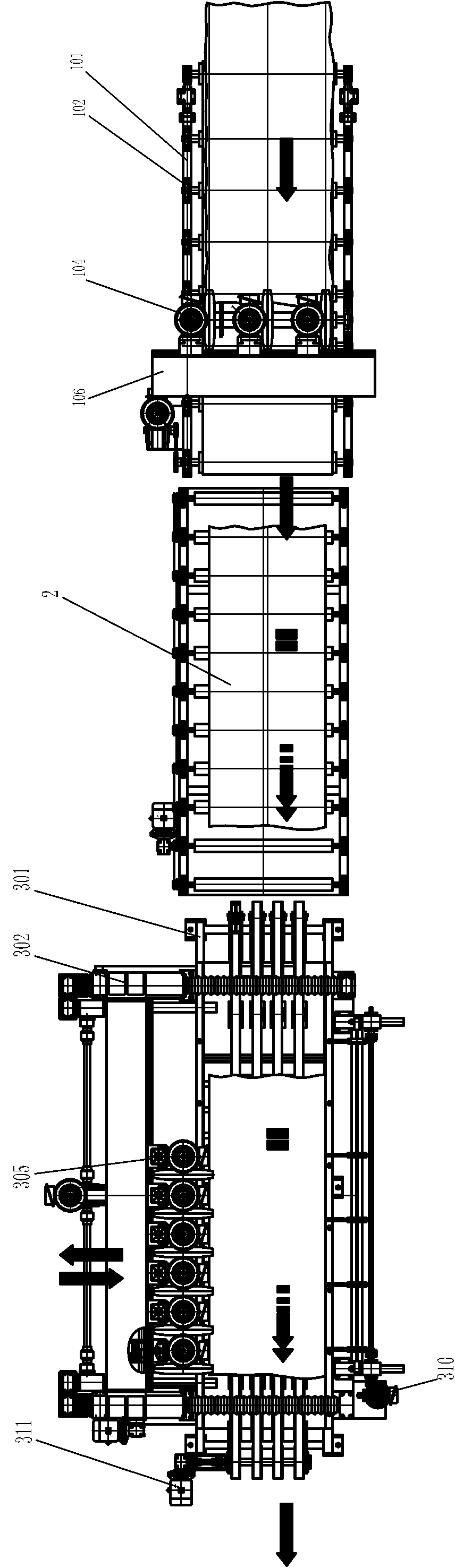

[0055] A fully automatic vertical and horizontal multi-cutting head combination trimming machine board edge trimming machine, such as figure 1 , 2 As shown, it includes: a longitudinal edge fixing machine 1, a plate cross-cutting machine 3, and an automatic controller. automated assembly line;

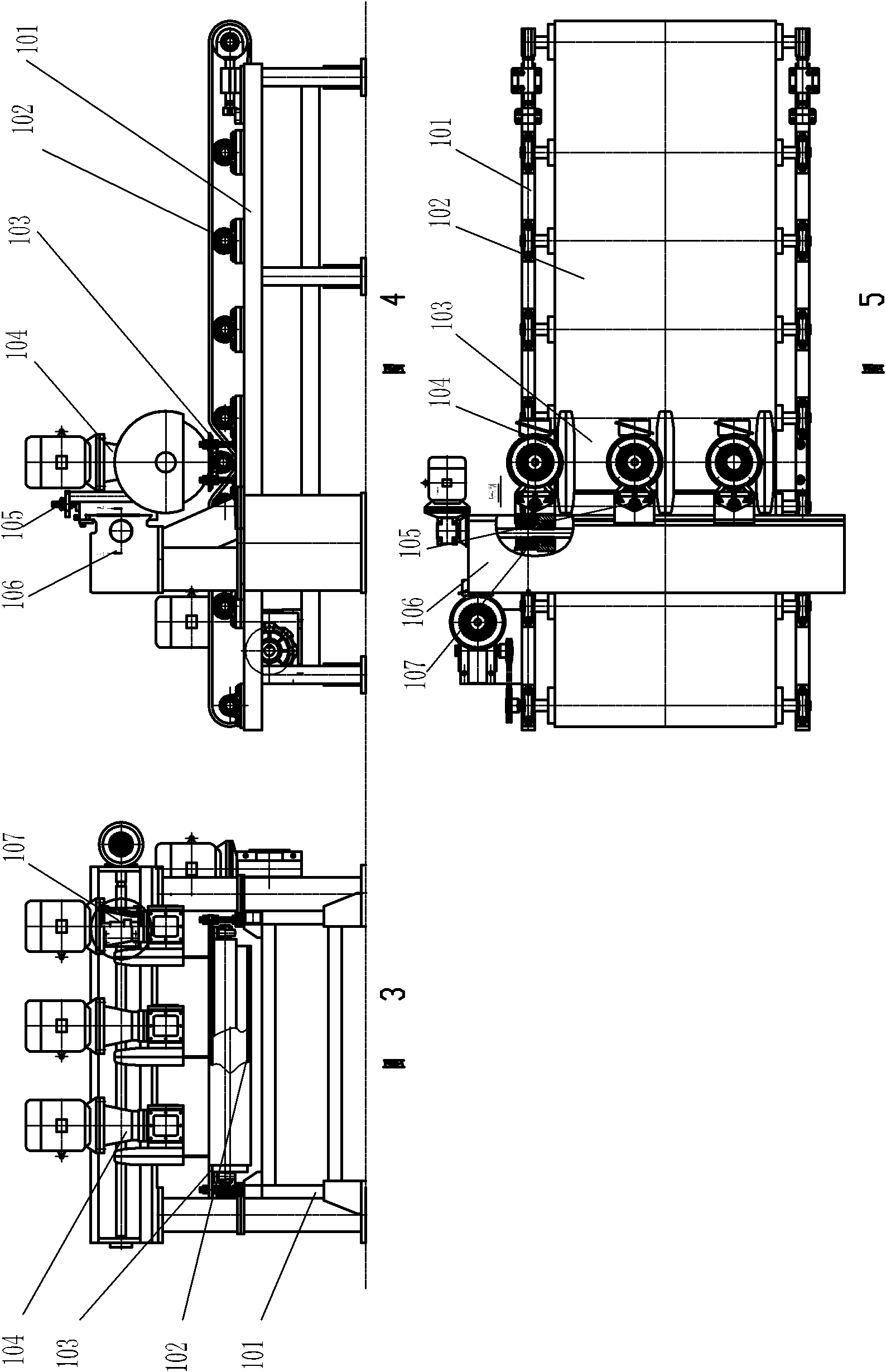

[0056] Described longitudinal edge fixing machine 1 is as Figure 3-5 , Figure 9-11 As shown: it is composed of the following components: frame 101 of vertical edge fixing machine, plate conveyor belt 102, independent cutting machine power head 103, independent cutting machine power head height adjustment device 105, independent cutting machine power head beam 106, independent cutting machine The horizontal adjustment device 107 of the power head or the pneumatic horizontal adjustment device 108 of the independent cutting machine power head, and the above-mentioned board conveyor belt 102 cutting board support and conveyor belt avoidance device 103 .

[0057] The frame 101 of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com