A structured sawing wire

A technology of sawing wire and hacksaw, applied in the field of structured sawing wire, can solve the problems of absence of cavities or protrusions, limited sawing effect, serious abrasive wear effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

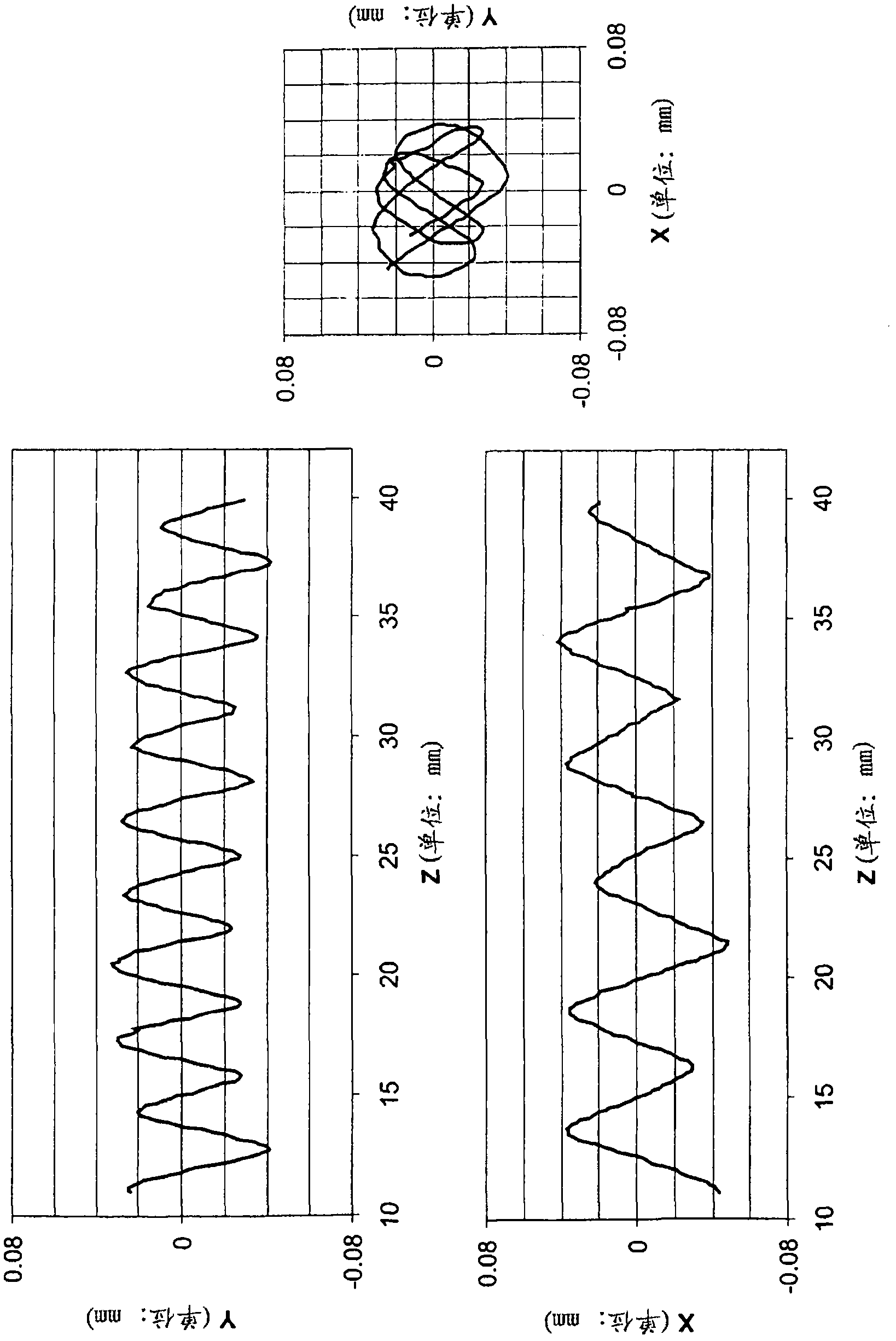

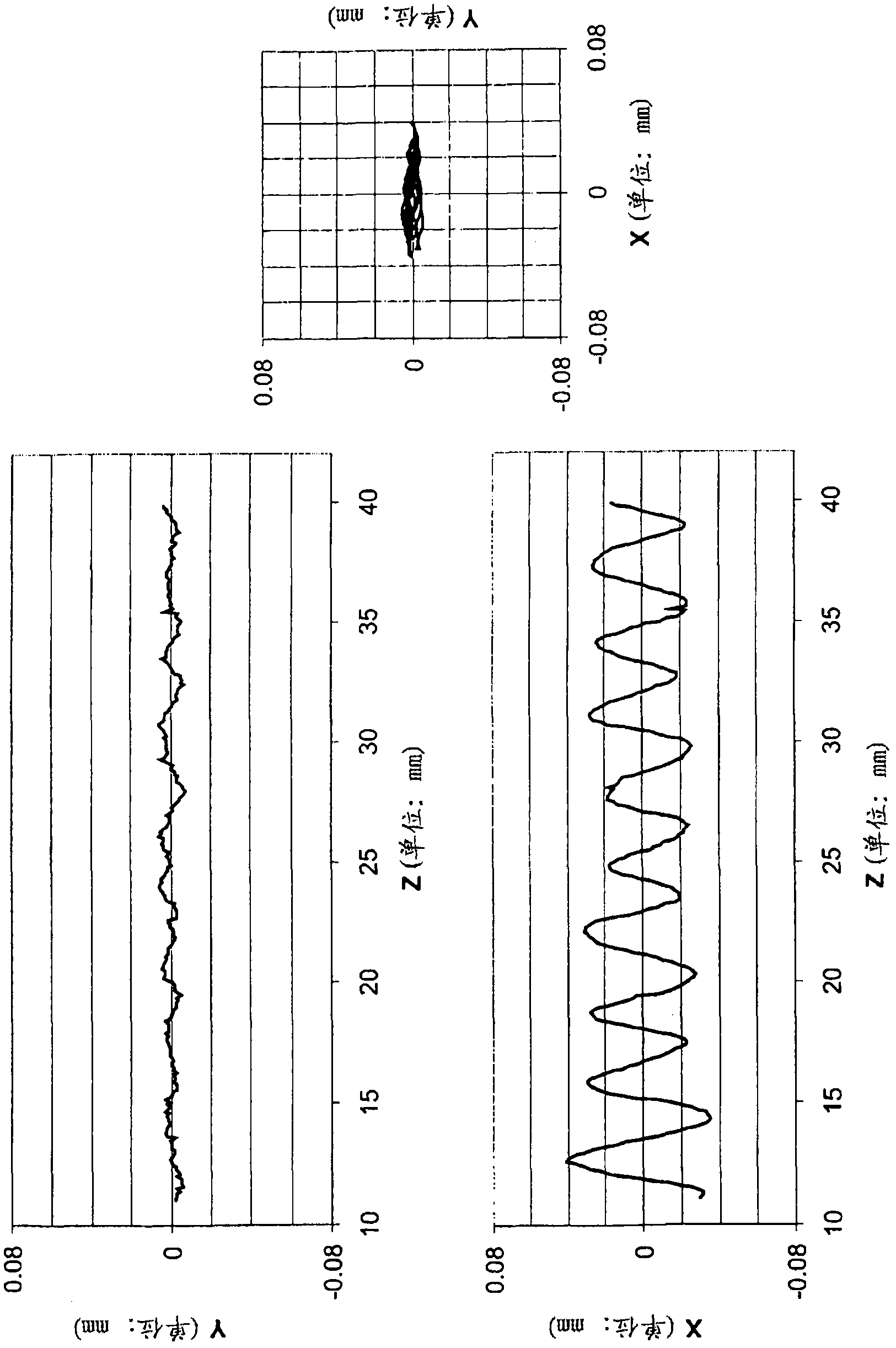

[0082] Figure 1a The shape of a prior art structured saw wire as described in WO2006 / 067062 is shown. The saw wire is circular with a diameter of 0.25 mm. As described in the penultimate third paragraph on page 8, the saw wire is scanned three-dimensionally, and these three figures show three projections of the saw wire center on the YZ, YX, and XZ planes. The wire has been rotated about the Z axis so that the projection clearly shows waves in two mutually perpendicular bending directions. The waveform on the YZ plane clearly shows a wavelength of about 3.0mm, while the projection on the XZ plane shows a longer wavelength of about 5.2mm. The half-amplitude of the waveform is about 0.04mm, making the diameter of the entire circumscribed cylinder of the wire about 0.33mm. This wire is hereinafter referred to as reference wire "Ref".

[0083] Contrary to Figure 3 in WO2006 / 067062, the projection of the thus shaped saw wire on the XY plane shows a Lissajous figure (not a cros...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com