Pneumatic tire and manufacturing method of pneumatic tire

A technology of pneumatic tires and tires, which is applied to tire parts, tires, tire edges, etc., can solve problems such as tire uniformity deterioration, and achieve the effects of maintaining uniformity, suppressing stress concentration, and uniform weight balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

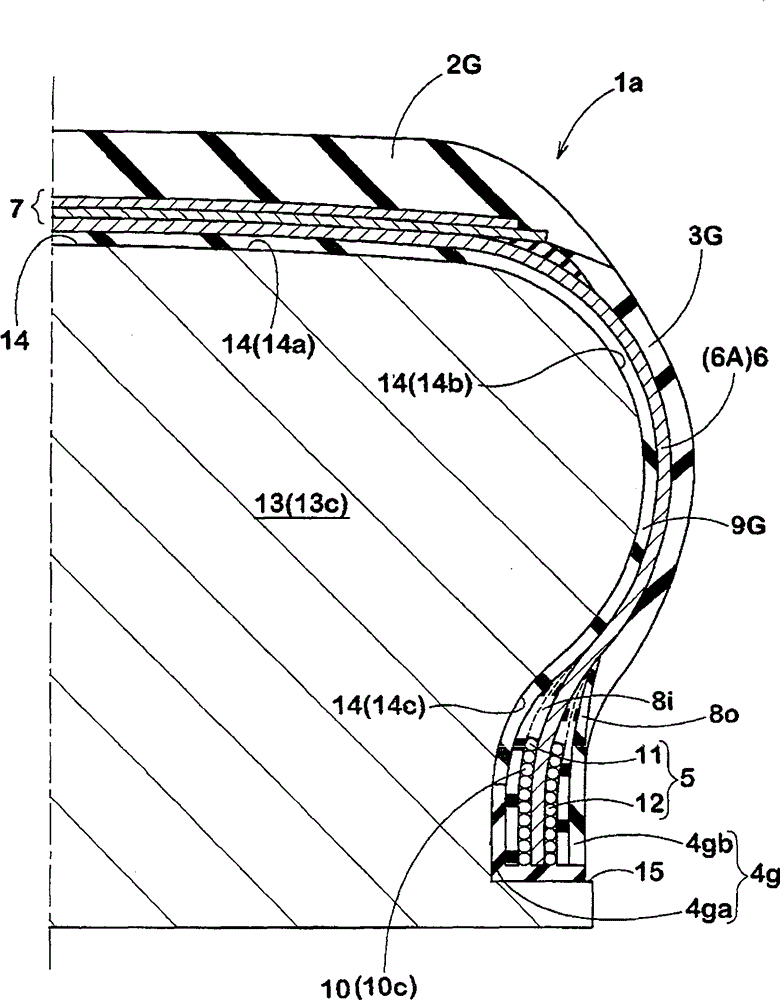

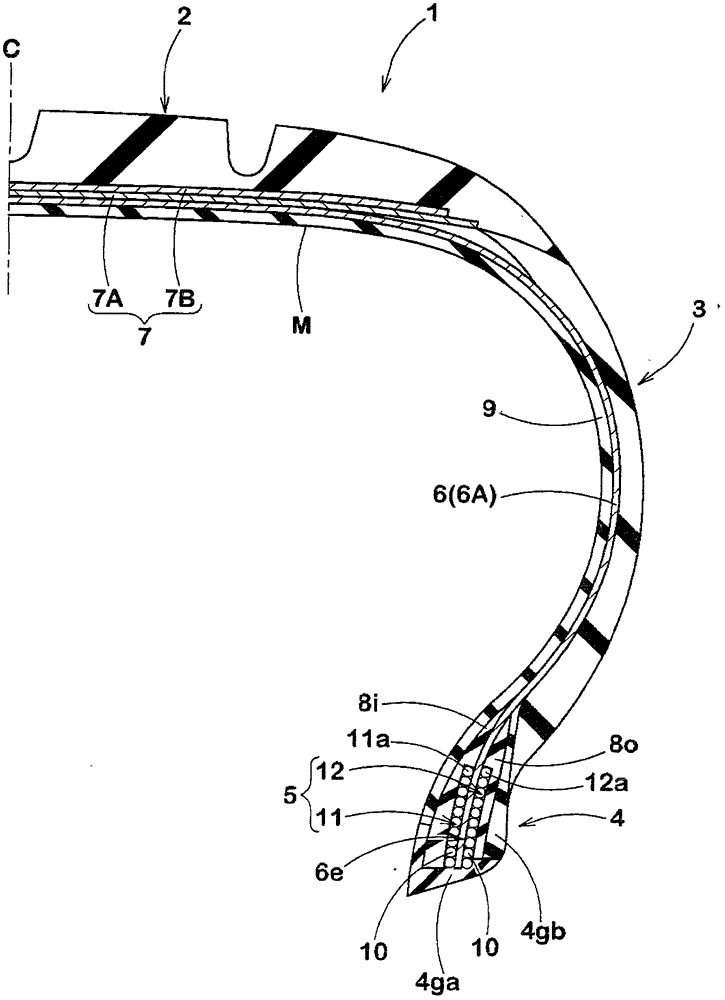

[0048] In order to confirm the effect of the present invention, by using Figure 4 A tire having a bead core according to the invention with the core shown and Figure 5 The conventional tires having bead cores shown in (a) and (b) were vulcanized to produce pneumatic tires, and the hydraulic pressure and uniformity tests were carried out. The main common specifications are as follows.

[0049] Carcass ply number: 1 piece

[0050] Carcass Cord Material: Polyester

[0051] Carcass cord angle: 88° (to tire equator)

[0052] Number of belt plies: 2 pieces

[0053] Belt Cord Material: Steel

[0054] Belt cord angle: +28°, -28° (to tire equator)

[0055] Rubber hardness of bead wire: 80 degrees

[0056] Wire Material of Bead Wire: Steel

[0057] Tire size: 195 / 65R15

[0058]

[0059] Each test tire rim was assembled to a 6.0JJ×15 rim, and water was filled into the tire cavity from the valve, and the breaking water pressure when the bead core was broken was measured five t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com