Straw and mushroom matrix compression forming machine

A molding machine and mushroom technology, which is applied to material molding presses, presses, manufacturing tools, etc., can solve the problems of small unit volume, high cost, large mushroom shed area, etc., and achieves simple and compact structure, cost saving, The effect of saving manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

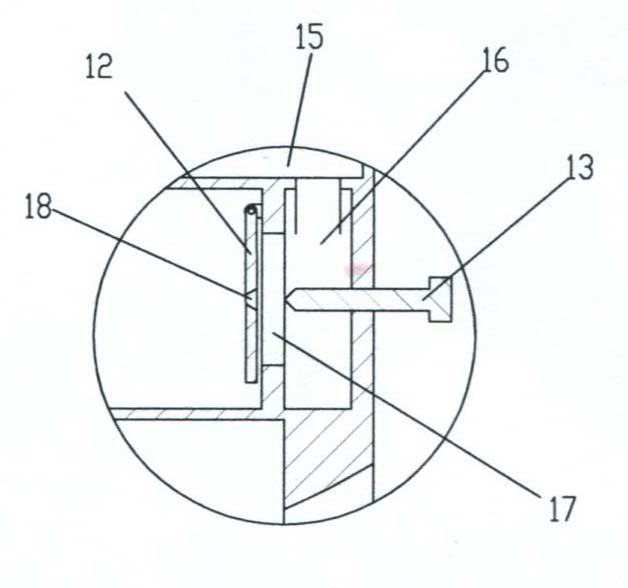

[0015] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0016] Structure of the present invention:

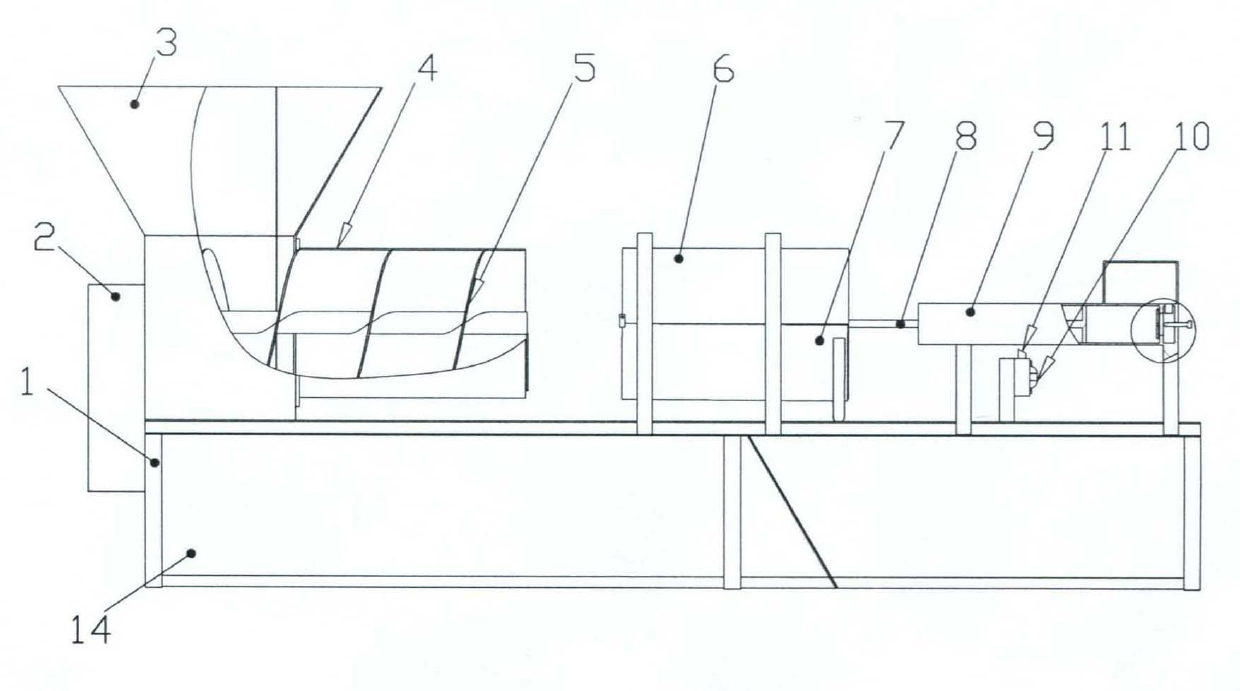

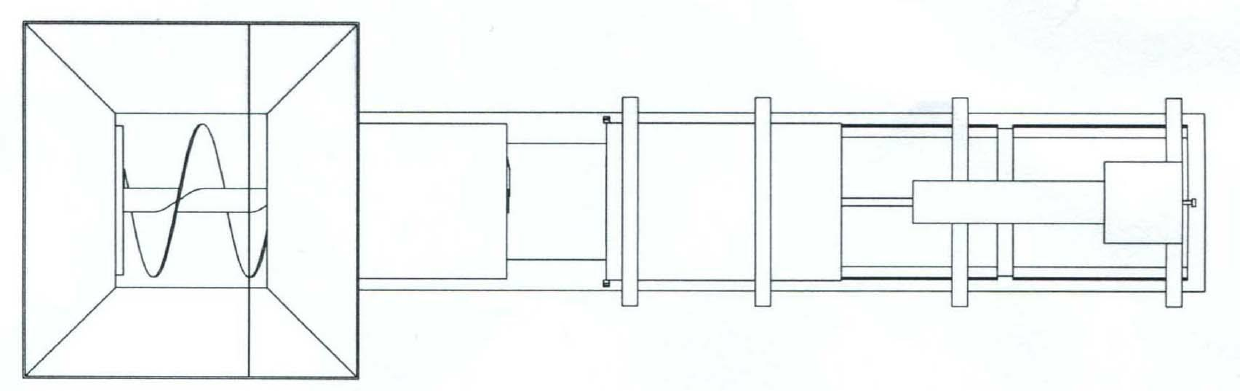

[0017] figure 1 As shown, the straw mushroom matrix compression molding machine is mainly composed of four parts: base I, discharger II, compactor III and mold IV. One end of the base 1 is installed into the raw material hopper and the discharger The part of the compactor is installed at the end of the other end, and the guide rail in the middle of the frame I is equipped with a mold that can move back and forth.

[0018] figure 1 and figure 2 As shown, the machine base I is a rectangular welded structure, and a sliding track is arranged on the upper part of the machine base I; the mold is set on the sliding track. A baffle 14 is provided outside the base I.

[0019] The discharger II includes a belt cover, a power transmission device 2, a hopper 3, a discharge cylinder 4 and a spiral core 5, the hopper 3 is instal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com